Jan . 11, 2025 09:48

Back to list

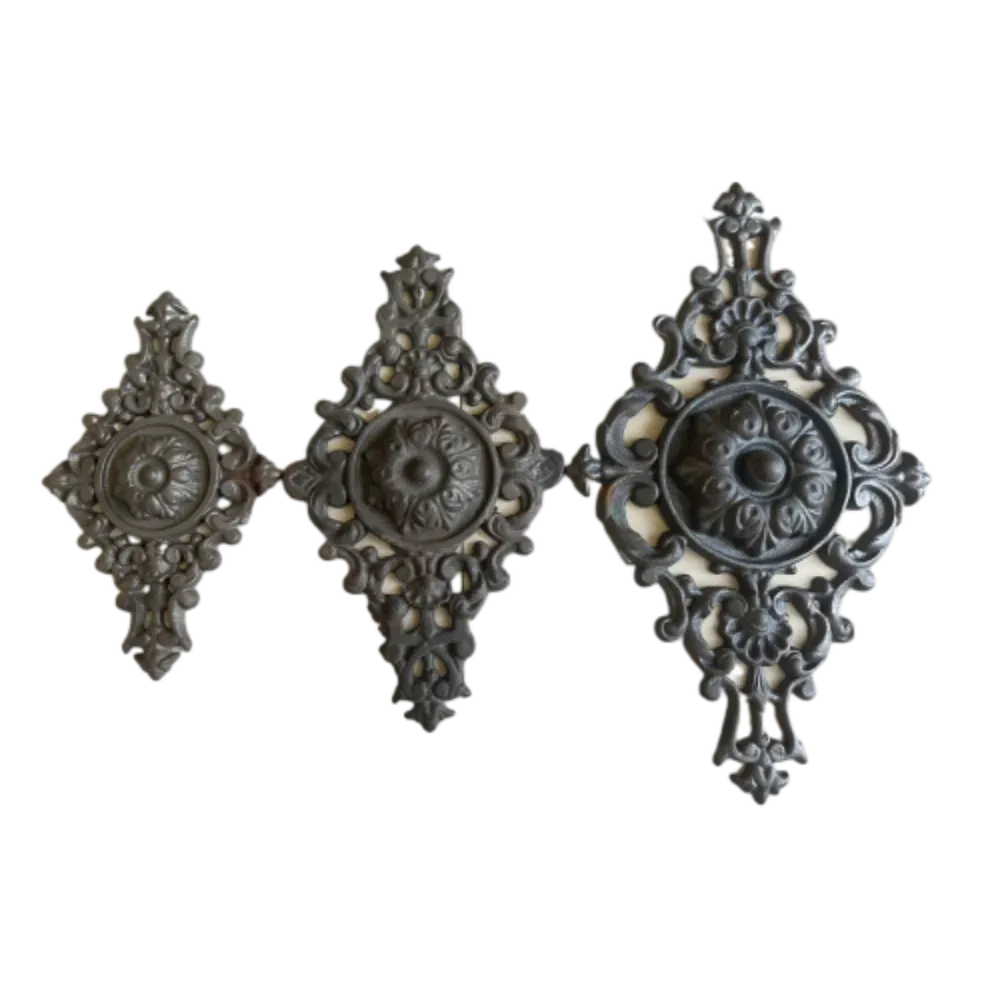

metal iron

In the realm of metallurgy and construction, metal iron continues to stand as a cornerstone material, prized for its robustness, versatility, and economic viability. The demand for iron is incessant, spanning across myriad industries such as automotive, aerospace, construction, and manufacturing. This article delves into the principal characteristics, applications, and enduring trust in metal iron, drawing from a wealth of experience and authoritative expertise in the field.

Ensuring quality in iron production and application is crucial. Meticulous processes such as smelting and refining are undertaken to eliminate impurities and augment desirable properties, aligning with strict standards set by authoritative bodies like the American Society for Testing and Materials (ASTM). These rigorous criteria ensure the metal's performance and longevity, underlining its trustworthiness in critical applications. Trust in Procurement Reliability in iron doesn't just rest on production techniques but also on the trust established in its procurement. Accredited suppliers with comprehensive ISO certifications assure quality and traceability, offering warranties and delivering materials that conform to stringent metallurgical requirements. Such assurances bolster confidence among engineers, designers, and builders, fostering a trusting relationship essential for the successful execution of projects. The Future of Iron Utilization As industries evolve, so too does the application of metal iron. With advancements in manufacturing processes, iron is becoming even more versatile. Innovations such as additive manufacturing (3D printing) with iron-based powders open up new possibilities for complex, bespoke iron components that maintain the material's strength while permitting unprecedented design freedom. Conclusion Iron’s relevance and indispensability across various domains are undisputed. Its economic viability, coupled with unmatched physical properties, cements its status as a quintessential industrial material. Guided by extensive experience, stringent quality controls, and continued innovations, iron will perpetually be woven into the fabric of industrial progress, trusted by experts and newcomers alike in their quest to build, innovate, and inspire.

Ensuring quality in iron production and application is crucial. Meticulous processes such as smelting and refining are undertaken to eliminate impurities and augment desirable properties, aligning with strict standards set by authoritative bodies like the American Society for Testing and Materials (ASTM). These rigorous criteria ensure the metal's performance and longevity, underlining its trustworthiness in critical applications. Trust in Procurement Reliability in iron doesn't just rest on production techniques but also on the trust established in its procurement. Accredited suppliers with comprehensive ISO certifications assure quality and traceability, offering warranties and delivering materials that conform to stringent metallurgical requirements. Such assurances bolster confidence among engineers, designers, and builders, fostering a trusting relationship essential for the successful execution of projects. The Future of Iron Utilization As industries evolve, so too does the application of metal iron. With advancements in manufacturing processes, iron is becoming even more versatile. Innovations such as additive manufacturing (3D printing) with iron-based powders open up new possibilities for complex, bespoke iron components that maintain the material's strength while permitting unprecedented design freedom. Conclusion Iron’s relevance and indispensability across various domains are undisputed. Its economic viability, coupled with unmatched physical properties, cements its status as a quintessential industrial material. Guided by extensive experience, stringent quality controls, and continued innovations, iron will perpetually be woven into the fabric of industrial progress, trusted by experts and newcomers alike in their quest to build, innovate, and inspire.

Prev:

Next:

Latest news

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters