Premium Decorative Iron Castings & Ornamental Cast Iron Parts

The Enduring Legacy and Modern Precision of Decorative Iron Castings in B2B Applications

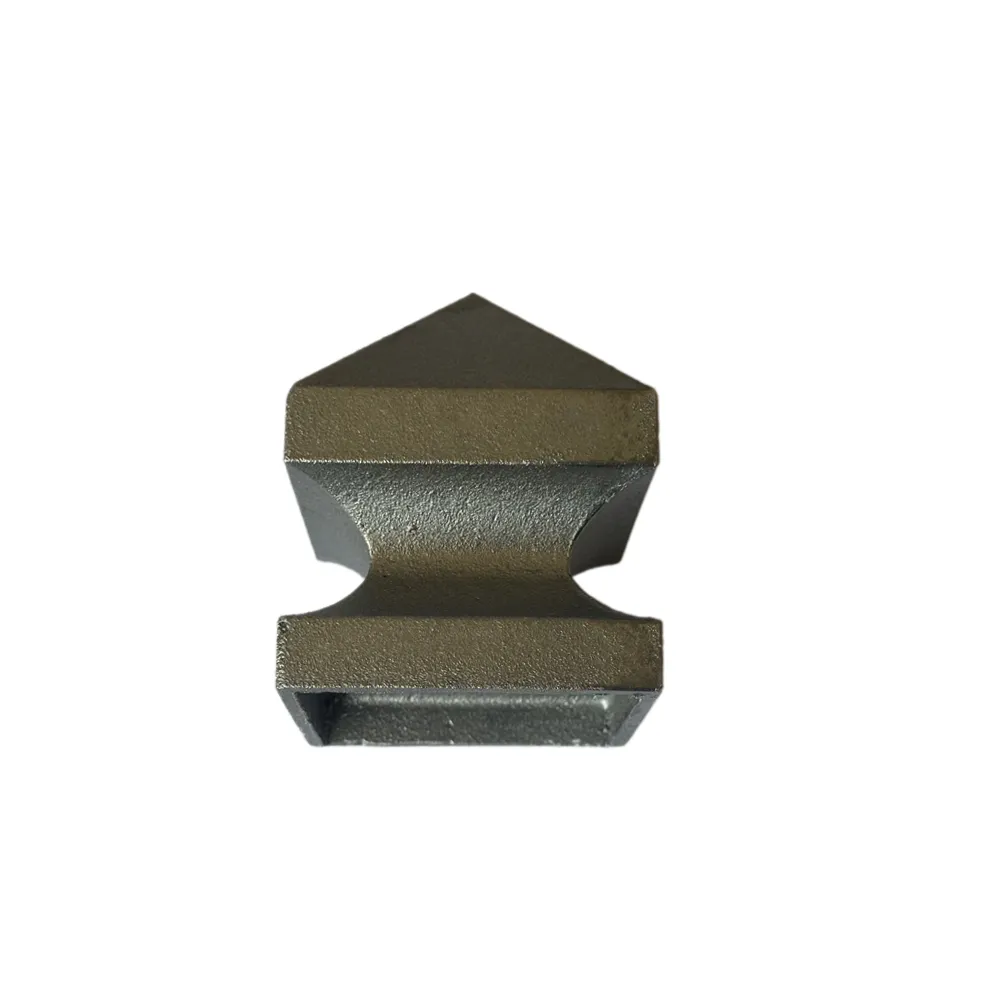

In the highly specialized domain of architectural and industrial material specification, the selection of components that blend robust structural integrity with profound aesthetic appeal is a paramount consideration. Among the myriad options, decorative iron castings emerge as a superior choice, offering an unparalleled synergy of durability, intricate design capability, and historical resonance. These essential components, ranging from ornate fence post caps and gate tops to elaborate balustrades and meticulously crafted street furniture, are not merely functional elements but also critical contributors to the overall visual narrative and long-term value of a project. The inherent metallurgical properties of cast iron—specifically, its exceptional compressive strength, superior vibration damping, and remarkable fluidity in its molten state allowing for the faithful reproduction of complex patterns—make it an ideal medium for creating elements that are not only designed for longevity but also serve as aesthetic focal points. The global demand for high-quality decorative iron castings continues its upward trajectory, spurred by a renewed emphasis on sustainable, enduring infrastructure, sophisticated urban planning, and the precise requirements of historical restoration projects where authenticity cannot be compromised. This comprehensive analysis aims to dissect the multifaceted world of decorative iron castings, providing B2B decision-makers, engineers, and procurement specialists with a granular understanding of the intricate manufacturing processes, diverse application scenarios, and the profound technical advantages that underscore their value proposition. We will delve into critical industry trends, elucidate the pertinent technical specifications, detail stringent quality assurance protocols, and highlight the pivotal role of customization in fulfilling highly specific project demands, thereby empowering our clients to make informed, strategic procurement decisions that align with both their operational performance objectives and their artistic aspirations. Understanding the nuances of material grades, advanced casting methodologies, and sophisticated post-processing treatments is indispensable for optimizing project outcomes and ensuring the specified ornamental iron casting achieves its full potential in any demanding environment.

Navigating Industry Trends and Market Dynamics for Decorative Iron Castings

The market for decorative iron castings is currently experiencing a robust resurgence, driven by a confluence of evolving architectural preferences, sustained urban development, and an increasing global commitment to heritage preservation. Urbanization remains a significant global accelerator, as municipal authorities and private developers worldwide invest heavily in public infrastructure projects—including revitalized parks, pedestrian zones, historical districts, and public buildings—all of which frequently integrate ornate cast iron elements for both functional robustness and enhanced aesthetic appeal. Concurrently, the burgeoning interest in historical preservation and meticulous restoration projects, particularly across Europe, North America, and parts of Asia, significantly amplifies the demand for bespoke ornamental iron castings that can faithfully replicate period-specific designs while seamlessly incorporating modern safety and durability standards. The luxury residential and high-end commercial property sectors are also critical drivers, often specifying decorative cast iron components to impart a timeless elegance, perceived gravitas, and an indisputable sense of robust construction that distinguishes their projects. Technological innovations in the casting industry, such as the deployment of advanced 3D printing for rapid prototyping of complex patterns and the implementation of sophisticated real-time melting and pouring control systems in foundries, are substantially improving the quality and precision of castings, leading to tighter dimensional tolerances, superior surface finishes, and a marked reduction in potential defects. These advancements significantly broaden the applicability and appeal of decorative iron castings in contemporary design.

A key overarching trend influencing the market for decorative cast iron is the increasing emphasis on sustainability. Given that cast iron is primarily produced from recycled ferrous scrap, it boasts an inherently lower embodied energy and carbon footprint compared to many materials produced from virgin resources. This makes it an exceptionally attractive choice for construction projects targeting environmental certifications such as LEED (Leadership in Energy and Environmental Design) or BREEAM (Building Research Establishment Environmental Assessment Method). Furthermore, continuous advancements in protective surface finishes, including highly durable powder coating systems, advanced e-coating techniques, and time-tested hot-dip galvanization, are dramatically extending the service life of these products. These protective layers enhance their resistance to environmental stressors such as corrosion, UV radiation, and abrasive wear, consequently reducing long-term maintenance costs and the frequency of replacements. This extended lifecycle and inherent recyclability contribute significantly to a project's overall sustainability profile and offer a compelling economic advantage for large-scale public works and commercial developments facing strict budget and environmental mandates. While the underlying raw material costs for iron maintain relative stability, the significant value added through intricate design, precision manufacturing, and superior finishing processes allows specialized manufacturers of ornamental cast iron parts to command premium pricing in niche market segments. The competitive landscape is dynamic, comprising both large-capacity foundries and highly specialized artisan workshops. Leading manufacturers differentiate themselves not only through innovative design and production efficiency but also through unwavering adherence to stringent quality controls, robust research and development initiatives, and comprehensive customer support, including bespoke design services, engineering consultation, and rapid prototyping capabilities. The increasing adoption of digital tools for design (Computer-Aided Design – CAD), manufacturing (Computer-Aided Manufacturing – CAM), and engineering simulation (Finite Element Analysis – FEA) further streamlines the product development cycle for complex decorative iron castings, enabling quicker turnaround times from initial concept to final product deployment. This continuous evolution firmly positions ornamental iron casting as a vital and progressively advanced segment within the broader materials and construction industries.

The Advanced Manufacturing Process of High-Quality Decorative Iron Castings

The creation of superior decorative iron castings is a sophisticated endeavor, meticulously blending centuries-old metallurgical traditions with cutting-edge engineering precision. The predominant method for these components is sand casting, lauded for its exceptional cost-effectiveness and remarkable versatility in producing complex and intricately detailed shapes. However, for applications demanding an ultra-fine surface finish, exceptionally tight dimensional accuracy, or particularly elaborate designs, the investment casting (lost wax) method may also be employed, albeit at a higher per-unit cost due to its more complex process. The journey typically commences with an exhaustive design phase, where intricate patterns are conceived and refined using advanced Computer-Aided Design (CAD) software. This digital blueprint ensures precise replication of the intended aesthetic and functional features, while also optimizing the design for ideal material flow during the casting process. These digital models are then translated into physical patterns, traditionally crafted from durable materials such as wood, metal, or high-density resin. Critically, these patterns are exact positive replicas of the final product but are engineered with a calculated oversized dimension to precisely account for the predictable shrinkage of the molten iron as it cools and solidifies, a crucial aspect of achieving accurate final dimensions in ornamental iron castings.

The core of the sand casting operation involves forming a robust mold cavity from specialized foundry sand. This process typically utilizes a two-part molding box, commonly referred to as a flask, which consists of an upper section (cope) and a lower section (drag). A carefully formulated mixture of high-quality sand (such as silica, zircon, or chromite), a binding agent (commonly bentonite clay), and water is meticulously compacted around the pattern. Once the sand mixture has solidified and achieved sufficient strength, the pattern is meticulously extracted, leaving an indelible impression that forms the mold cavity. For creating internal features, hollow sections, or undercuts within the final casting, additional sand cores, independently produced and precisely positioned, are strategically inserted into the mold. The selection of the iron alloy is paramount for decorative iron castings; typically, gray iron (conforming to ASTM A48 Class 20 through Class 40, offering excellent castability and damping properties) or ductile iron (conforming to ASTM A536 Grades such as 60-40-18 to 80-55-06, providing enhanced tensile strength, ductility, and impact resistance) is chosen based on the specific mechanical property requirements and the intended application’s structural demands. The molten iron, often prepared in advanced induction furnaces for precise temperature control and minimized impurities, is then carefully poured into the prepared mold cavity. Pouring temperatures are stringently controlled, typically ranging from 1350°C to 1450°C, to ensure complete mold fill-out, faithful reproduction of intricate details, and minimal porosity. After a controlled solidification period, the casting is carefully removed from the sand mold through a process known as shakeout. A significant advantage of sand casting is the high recyclability of the molding sand, underscoring the sustainable credentials of this manufacturing method for decorative cast iron production.

The post-casting operations are equally crucial for transforming raw castings into refined, high-performance ornamental cast iron parts. This phase commences with fettling, where excess material such as risers (feeders for molten metal) and gates (molten metal entry channels) are meticulously removed, and any undesirable flash (thin excess material) is carefully ground off. Subsequently, shot blasting or sandblasting techniques are applied to thoroughly clean the surface, remove residual sand and scale, and achieve a uniform, aesthetically pleasing finish, preparing the casting for subsequent inspections and protective treatments. For components demanding exceptional dimensional accuracy or specific surface characteristics (e.g., precise holes or mating surfaces), advanced CNC machining may be integrated for precision drilling, tapping, or milling operations. Heat treatment processes, such as annealing or normalizing, are often applied to ductile iron castings to optimize their mechanical properties, specifically enhancing their ductility and improving machinability, which is vital for components that may undergo further fabrication or assembly. Throughout these stages, rigorous inspection protocols are systematically implemented, encompassing comprehensive visual inspections for surface defects, precise dimensional checks utilizing calibrated calipers and gauges, and the deployment of advanced non-destructive testing (NDT) methods. These NDT techniques include ultrasonic testing for detecting internal flaws, magnetic particle inspection for identifying surface and near-surface discontinuities, and X-ray radiography for highly critical applications requiring absolute internal integrity verification. Finally, the application of high-performance surface coatings is a critical step in ensuring the longevity and aesthetic appeal of the decorative iron castings. Options include robust primer systems, high-durability paints, advanced powder coatings offering superior chip and UV resistance, or the ultimate protection of hot-dip galvanization. These coatings provide paramount corrosion resistance, significantly extending the service life of the product, especially when deployed in harsh outdoor environments, such as coastal areas, or specialized industrial settings like petrochemical facilities and water treatment plants where resistance to corrosive agents and chemical exposure is paramount for maintaining structural integrity and operational efficiency. This multi-stage, precision-driven process ensures that each piece of ornamental iron casting meets or exceeds the most stringent industry standards and bespoke client specifications.

Technical Parameters and Material Specifications: The Core of Ornamental Cast Iron Parts Performance

The discerning selection of the appropriate material grade and a profound understanding of the precise technical parameters are foundational for guaranteeing the enduring longevity, optimal performance, and structural integrity of ornamental cast iron parts in their intended, often demanding, applications. For purely decorative and static load-bearing architectural applications where intricate detailing is paramount, gray cast iron (e.g., ASTM A48 Class 20, 25, 30, or 35) is frequently the material of choice. This preference stems from its exceptional castability, which enables the faithful reproduction of fine details from patterns, its good machinability for subsequent finishing, and its superior damping capacity that is beneficial in certain structural contexts. While inherently less ductile than steel, its remarkable compressive strength and rigidity render it an outstanding material for static elements such as columns, bases, and intricate railings. Conversely, ductile iron (e.g., ASTM A536 Grades 60-40-18, 65-45-12, or 80-55-06) is specifically engineered and preferred when a project demands higher tensile strength, superior impact resistance, or a measurable degree of ductility, making it suitable for components that may experience dynamic loads, bending stresses, or require improved fracture toughness. The defining characteristic of ductile iron is its microstructure, where graphite forms spherical nodules rather than the flake-like structures found in gray iron; this spheroidization significantly enhances its mechanical properties without compromising its inherently excellent castability. This careful material selection is paramount in ensuring the functional and aesthetic success of every piece of decorative iron castings.

Critical technical parameters that define the performance of decorative iron castings encompass detailed chemical composition, verified mechanical properties, stringent dimensional tolerances, and precise surface finish specifications. The typical chemical composition for gray iron generally involves carbon (3.0-3.5%), silicon (1.5-2.5%), manganese (0.5-1.0%), with controlled limits on phosphorus (max 0.15%) and sulfur (max 0.15%); the precise percentages of these elements critically influence the final properties such as strength, hardness, and resistance to chilling. For ductile iron, typical compositions include carbon (3.4-3.9%), silicon (2.0-3.0%), manganese (0.2-0.6%), and trace amounts of magnesium and cerium, which are essential for inducing the desired spheroidization of graphite. Mechanical properties, rigorously tested and documented according to ASTM standards, include crucial metrics such as tensile strength, yield strength (specifically for ductile iron, as gray iron typically exhibits no distinct yield point), elongation (a measure of ductility, primarily for ductile iron), Brinell hardness (HB), and modulus of elasticity. Dimensional tolerances, often guided by international standards like ISO 8062 (Casting Dimension Tolerances) or explicitly defined by intricate customer-specific engineering drawings, dictate the permissible deviation from the nominal dimensions of the cast component, directly influencing subsequent machining requirements and the seamless fitment into larger assemblies. Surface roughness, typically quantified in Ra (arithmetic average), is directly influenced by the chosen molding process (e.g., sand casting yields rougher surfaces than investment casting) and the efficacy of post-casting finishing operations; this parameter plays a pivotal role in both the aesthetic quality and the adherence performance of applied protective coatings.

Furthermore, the choice and application of a protective coating system are integral to the long-term performance and extended service life of decorative cast iron, especially when deployed in outdoor or chemically corrosive environments. Prominent options include hot-dip galvanization, which provides unparalleled cathodic corrosion protection by creating a robust metallurgical bond of zinc to the iron surface, even in the presence of minor surface scratches. This can be followed by high-performance primer and paint systems for aesthetic customization and moderate protection, or advanced powder coatings that deliver a highly durable, chip-resistant finish with excellent UV stability and a wide array of color options. The precise thickness, adhesion, and uniformity of these coatings are governed by international standards such as ASTM A123/A123M for hot-dip galvanizing or specific coating manufacturer specifications, ensuring maximum protection. For highly specialized applications within industries such as petrochemical processing, metallurgy, or wastewater treatment, where components may be exposed to aggressive chemical agents, extreme temperatures, or abrasive slurries, the selection might necessitate specialized alloys or multi-layer coating systems engineered for specific chemical resistances. Our unwavering commitment to delivering superior decorative iron castings is reflected in our rigorous analysis and precise control of these multifaceted technical parameters. This meticulous approach ensures that every product, from a seemingly simple decorative cast iron post collar to complex sections of an ornamental cast iron fence, not only meets but demonstrably exceeds the most exacting functional and aesthetic expectations of our discerning B2B clients, guaranteeing long-term reliability and satisfaction.

Typical Technical Parameters for Decorative Iron Castings

| Parameter | Gray Cast Iron (ASTM A48 Class 30) | Ductile Iron (ASTM A536 Grade 65-45-12) | Notes |

|---|---|---|---|

| Tensile Strength (min) | 207 MPa (30,000 psi) | 448 MPa (65,000 psi) | Refers to the ultimate tensile strength. |

| Yield Strength (min) | N/A (Brittle Material) | 310 MPa (45,000 psi) | Applicable to ductile iron only. |

| Elongation (min) | N/A (Brittle Material) | 12% | Measure of ductility, applicable to ductile iron. |

| Brinell Hardness (HB) | 187-241 | 187-255 | Indicates resistance to indentation. |

| Density | 7.1 g/cm³ (0.256 lb/in³) | 7.1 g/cm³ (0.256 lb/in³) | Typical density for cast iron alloys. |

| Typical Wall Thickness | 3-100 mm (0.12-4 in) | 3-100 mm (0.12-4 in) | Dependent on design complexity and application. |

| Dimensional Tolerance | CT10-CT13 (ISO 8062) | CT9-CT12 (ISO 8062) | Depends on casting method and size; tighter for investment casting. |

| Surface Roughness (Ra) | 12.5-50 µm | 12.5-50 µm | Achievable with sand casting and shot blasting. Finer with precision casting. |

| Corrosion Resistance | Good (with proper coating) | Excellent (with proper coating) | Enhanced significantly by galvanizing or powder coating. |

Versatile Application Scenarios and Profound Technical Advantages of Decorative Iron Castings

The inherent robustness and timeless aesthetic appeal of decorative iron castings render them indispensable across an expansive spectrum of industries and application environments. In the critical domain of urban planning and public infrastructure, these castings are ubiquitously utilized for durable street furniture, including exquisitely designed benches, classically styled lamp posts, robust bollards, and aesthetically integrated litter bins, all of which contribute significantly to the historical charm, functional resilience, and overall visual coherence of public spaces. For instance, an ornamental cast iron fence offers not only superior longevity and a classic elegance but also enhanced security compared to many fabricated alternatives, making it the preferred choice for meticulously maintained parks, sensitive heritage sites, and discerning private estates that require both aesthetic appeal and robust perimeter security. Residential and high-end commercial properties frequently integrate these sophisticated castings for majestic gates, ornate railings, elaborate balconies, and particularly for the architectural finesse provided by a decorative cast iron post collar, which adds a refined finishing touch and structural articulation to columns and posts. In large-scale historical preservation and restoration projects, custom-manufactured ornamental iron casting pieces are absolutely crucial for meticulously restoring period-appropriate authenticity to historical façades, interior architectural details, and outdoor installations, where the precise replication of original designs and the adherence to historical integrity are non-negotiable requirements. The unparalleled versatility inherent in the casting process allows for the creation of exceptionally intricate and highly detailed patterns that are either prohibitively difficult or economically unfeasible to achieve through alternative metalworking techniques such as forging, welding, or sheet metal fabrication, thus making decorative iron castings a unique solution for complex design challenges.

Beyond their significant architectural and purely decorative roles, decorative iron castings offer a suite of profound technical advantages that are highly valued in various B2B applications. Their exceptional compressive strength makes them ideally suited for load-bearing applications, guaranteeing structural stability and integrity over remarkably long periods, often spanning many decades, or even centuries, in heritage structures. The superior vibration damping properties of cast iron are particularly beneficial in specific industrial settings where the mitigation of machinery vibration is critical for operational stability and equipment longevity. The material’s inherent resistance to abrasion and wear, especially in specific high-grade compositions, further extends its applicability to components used in heavy machinery or challenging industrial environments where continuous friction or abrasive contact is present. Furthermore, when properly protected with advanced surface coatings, such as hot-dip galvanization followed by a high-performance powder coating, decorative iron castings demonstrate exceptional and long-lasting corrosion resistance, significantly outperforming many other ferrous metals when exposed to harsh outdoor elements. This makes them perfectly suited for deployment in demanding environments, including corrosive marine atmospheres, high-traffic public parks, and even certain light industrial applications where consistent exposure to environmental elements or mild chemical agents is unavoidable. The remarkable longevity and minimal maintenance requirements of these products directly translate into significantly lower lifecycle costs, reducing the need for frequent replacement and ongoing upkeep, which represents a substantial economic advantage for large-scale infrastructure projects and municipal budgets that are under constant pressure to optimize long-term expenditure.

Moreover, the inherently low thermal expansion coefficient of cast iron contributes to its remarkable dimensional stability across a wide range of fluctuating temperatures, thereby minimizing thermal stress and potential deformation, which is crucial for large, exposed architectural elements. In highly specialized industrial contexts, while not typically the primary material for the core process equipment in, for example, petrochemical plants or metallurgical facilities, ornamental cast iron parts find critical roles as durable protective casings, robust structural supports, or specialized architectural components within these challenging environments. For instance, in water supply and drainage systems, decorative cast iron elements are employed not only for aesthetically pleasing covers and gratings but also for highly durable, pressure-resistant fittings in non-potable water applications, or as protective enclosures for vital underground infrastructure components, leveraging their inherent strength and corrosion resistance. The intrinsic ability of the casting process to produce complex, hollow sections with optimized wall thicknesses can also contribute to overall weight optimization without compromising essential structural integrity, which can translate into energy savings during transportation, installation, and over the lifespan of dynamic systems. Ultimately, the powerful fusion of unparalleled aesthetic flexibility with formidable technical performance solidifies the position of decorative iron castings as a premium and highly advantageous choice for discerning B2B buyers who prioritize both enduring beauty and uncompromising, long-term functionality in their critical projects. The comprehensive benefits derived from their application underscore their value as a strategic material choice that delivers on both form and function.

Strategic Partner Selection: Manufacturer Comparison and Advanced Custom Solutions for Decorative Iron Castings

For B2B procurement professionals and engineering teams, the strategic selection of a manufacturing partner for decorative iron castings is a pivotal decision that directly influences project timelines, budget adherence, and, most importantly, the ultimate quality, performance, and longevity of the final installation. A comprehensive manufacturer comparison must extend far beyond a superficial analysis of unit pricing; it must meticulously encompass a vendor’s demonstrable track record, unwavering adherence to stringent international quality standards, advanced technological capabilities, and a robust, proven capacity for delivering highly specialized custom solutions. An experienced and reputable manufacturer will consistently demonstrate profound expertise across all facets of metallurgy, intricate pattern making, and various casting techniques—including sand casting for its cost-effectiveness and versatility, and lost wax (investment) casting for its superior precision and surface finish. This holistic expertise ensures that the final ornamental iron casting product not only meticulously matches the specified design parameters but also performs optimally under the diverse and often challenging environmental conditions it will encounter. Crucially, verifiable certifications such as ISO 9001:2015 are non-negotiable indicators of a manufacturer's deep-seated commitment to robust quality management systems, encompassing every stage from initial raw material sourcing and rigorous quality control to precision manufacturing, installation guidance, and diligent post-sales servicing. Furthermore, a truly reliable manufacturer will have cultivated long-standing, stable relationships with top-tier raw material suppliers, guaranteeing the consistent quality of ferrous scrap, virgin iron, and alloying elements. They should also possess access to and proficiency with state-of-the-art foundry equipment, including advanced induction furnaces for ultra-precise temperature control during melting, automated pouring systems for consistent fill rates, and sophisticated shot blasting facilities for achieving superior and uniform surface preparation essential for optimal coating adhesion.

The distinguished ability to provide comprehensive and agile custom solutions is arguably the hallmark of a premier supplier of decorative iron castings. Many contemporary architectural, urban infrastructure, and historical restoration projects necessitate unique designs, dimensions, or functional specifications that simply cannot be fulfilled by readily available, off-the-shelf products. This critical requirement mandates a manufacturing partner with profound in-house design and engineering capabilities. Such capabilities typically include advanced CAD/CAM software for meticulous pattern development and digital prototyping, coupled with sophisticated Finite Element Analysis (FEA) for rigorous structural integrity validation under predicted load conditions. Customization options for ornamental iron casting components can span a vast array of aspects: from entirely unique aesthetic designs for complex fence panels or distinctive gate tops, to precise dimensional adjustments to seamlessly integrate with existing or historical structures, the selection of specific material grades (e.g., opting for higher-strength ductile iron for security barriers or specific gray iron grades for intricate historical reproductions), or the application of bespoke finishing treatments (e.g., precise color matching for specialized powder coatings, anti-graffiti finishes, or enhanced anti-corrosion treatments tailored for extremely aggressive coastal or industrial environments). A truly responsive manufacturer will offer rapid prototyping services, leveraging technologies like 3D printing for patterns, to enable quick validation of complex designs prior to full-scale production, thereby minimizing project risks and ensuring absolute client satisfaction with the final product. Moreover, they should possess flexible and scalable production capacities, capable of efficiently handling both small-batch, highly customized artisan orders for a single heritage building and large-volume productions for extensive public works or multi-phase residential developments, without compromising on quality or schedule.

Furthermore, a thorough assessment of a manufacturer's documented service record, verifiable client testimonials, and their proactive approach to after-sales support is indispensable for establishing trustworthiness. A robust portfolio of successfully completed projects, particularly those similar in scope, complexity, or aesthetic demands to your own, provides tangible, irrefutable evidence of their capabilities and reliability. Long-standing collaborative partnerships with esteemed architects, leading contractors, and influential urban planners signify a deep level of trust and consistent reliability within the highly competitive industry of ornamental iron casting. Manufacturers who consistently invest in cutting-edge research and development—focused on refining casting processes, exploring novel ferrous alloys, or enhancing advanced coating technologies—demonstrate a forward-thinking, innovative approach that directly benefits their clients through the provision of increasingly durable, high-performance, and cost-effective products. Our company stands as a testament to these critical attributes, offering a unique and powerful synergy of traditional, time-honored craftsmanship fused with modern technological prowess. We are unequivocally committed to engaging in close, collaborative partnerships with our clients, guiding them seamlessly from the initial conceptualization and detailed drawing phase through meticulous prototyping and ultimately to precision final production. This unwavering dedication ensures that every cast iron ornamental fence component, every intricate decorative cast iron post collar, and every bespoke architectural element we deliver not only meets but demonstrably surpasses their exacting standards for quality, design fidelity, and long-term performance, thereby solidifying our esteemed position as the preferred, trusted partner in the global market for decorative iron castings.

Real-World Application Cases and Client Success Stories Leveraging Decorative Iron Castings

The tangible and enduring value of high-quality decorative iron castings is most vividly demonstrated through their successful deployment and long-term performance in a diverse array of real-world projects, underscoring their versatility and reliability. Our extensive portfolio proudly showcases numerous instances where our specialized expertise in ornamental iron casting has yielded exceptional results for a wide spectrum of clients, encompassing significant public works, prestigious commercial developments, and exquisite private estates. For example, a recent, highly visible collaboration with the City of "Veridian Heights" involved the large-scale supply of custom-designed decorative cast iron post collar units and meticulously crafted lamp post bases for a multi-phase downtown revitalization initiative. The project presented a complex challenge: to harmoniously match the classical aesthetic of historical street furniture prevalent in the city's heritage districts while seamlessly integrating modern LED lighting technology and simultaneously ensuring extreme durability against the rigors of urban wear, vandalism, and environmental exposure. Our engineering team responded by providing precise CAD models, developing custom patterns, and producing high-strength ductile iron castings that were then expertly finished with a multi-layer architectural powder coating system. This comprehensive solution ensured not only an impeccable historical authenticity but also guaranteed an expected service life exceeding 50 years, significantly reducing the city's long-term maintenance burden. The project was completed ahead of schedule and precisely within budget, drawing widespread commendations from city urban planners and residents alike for the dramatically enhanced streetscape and the undeniable, enduring quality of the installations, which became new landmarks. This case study powerfully illustrates our profound ability to effectively merge intricate artistic design with robust, contemporary engineering principles, consistently delivering solutions that are both visually stunning and inherently resilient for decorative iron castings.

Another particularly notable application involved our contribution to a luxury residential development situated along a challenging coastal region, notorious for its severe salt spray and consistently high humidity. The discerning client specifically required elegant fence post caps and majestic gate tops that could withstand these extremely corrosive conditions without exhibiting premature degradation or unsightly rust. In response, we expertly recommended and subsequently supplied high-grade gray iron castings that were subjected to a dual-layer protective treatment: initial hot-dip galvanization followed by a specialized marine-grade powder coating. The hot-dip galvanization process provided a robust, sacrificial zinc layer that offered superior cathodic protection against rust, even if the primary coating experienced minor surface abrasions. The subsequent marine-grade powder coating ensured exceptional resistance to UV degradation, saltwater ingress, and mechanical damage, maintaining its aesthetic integrity for decades. This multi-layered protective system demonstrably extends the product’s lifespan in highly corrosive environments, representing a critical long-term advantage for the developer. Feedback from the project developer consistently highlighted the exceptional visual appeal of these ornamental iron castings, their seamless integration with the property's bespoke architectural design, and the palpable sense of inherent quality and robust durability. This successful deployment unequivocally exemplifies our technical acumen in precise material selection and advanced surface treatment methodologies for highly demanding applications of decorative cast iron.

Furthermore, while less "decorative" in the traditional sense, our extensive casting capabilities extend to supplying robust cast iron components for challenging industrial sectors such as metallurgy and wastewater treatment facilities. These applications, though primarily functional, implicitly leverage the same core expertise in casting large, complex shapes with precise dimensional tolerances and high resistance to harsh environments. For instance, we provided custom-engineered ductile iron grates for a major municipal wastewater treatment plant. These grates were specifically designed to withstand significant operational loads and resist chemical exposure from treated water, demonstrating the material’s adaptability. While not visually ornamental, the underlying casting fidelity and superior material properties were critical. In another complex case, a large historical railway station required the painstaking replication of its original decorative cast iron columns and intricate balustrades, some of which had deteriorated beyond repair. Our specialized team undertook a meticulous reverse-engineering process, employing advanced 3D scanning technologies on surviving original elements to generate precise digital models and subsequent patterns. The resultant castings, produced to exacting ASTM A48 Class 35 specifications and finished with a durable, historically accurate architectural paint system, were visually indistinguishable from the originals. Crucially, they boasted enhanced structural integrity and longevity, contributing significantly to the station's preservation, functional upgrade, and aesthetic revitalization. These diverse and challenging case studies collectively provide compelling evidence of our comprehensive capabilities, ranging from intricate artistic replication for iconic architectural projects to engineering robust, high-performance casting solutions for demanding industrial and public infrastructure applications, consistently prioritizing long-term value, uncompromising quality, and the ultimate satisfaction of our discerning clientele when delivering decorative iron castings.

Unwavering Quality Assurance, International Certifications, and the Unmatched Long-Term Performance of Decorative Cast Iron

In the highly competitive and demanding B2B landscape, particularly when specifying durable and critical components like decorative iron castings, robust quality assurance is not merely a beneficial addition but rather an absolute, non-negotiable cornerstone of product reliability, operational safety, and long-term project value. Our unwavering commitment to manufacturing excellence is meticulously underpinned by stringent adherence to and certification under internationally recognized quality management standards, most notably ISO 9001:2015. This globally accepted standard mandates a systematic, process-oriented approach to every facet of our operations—from the initial design and developmental stages through comprehensive production, meticulous installation guidance, and dedicated post-sales servicing—thereby ensuring consistently superior product quality, continuous operational improvement, and minimized risk. Beyond the foundational ISO certification, our entire product range for ornamental iron casting rigorously conforms to all relevant ASTM (American Society for Testing and Materials) standards for cast iron, including critical specifications like ASTM A48 for gray iron and ASTM A536 for ductile iron, which precisely define the minimum required mechanical properties and acceptable chemical compositions. Furthermore, exceptionally high dimensional accuracy is consistently maintained through strict compliance with ISO 8062 (Casting Dimension Tolerances) and an extensive regime of meticulous, in-process quality control measures applied at every manufacturing stage. Each production batch of decorative iron castings undergoes comprehensive material testing, including spectrographic analysis of both raw materials and molten metal to precisely verify chemical composition, alongside rigorous mechanical testing (e.g., tensile strength, hardness, and elongation) performed on dedicated test coupons extracted from actual production runs. For critical structural components or applications demanding absolute integrity, advanced non-destructive testing (NDT) methods are routinely employed. These sophisticated techniques include detailed visual inspections for surface defects, highly sensitive magnetic particle inspection for detecting sub-surface cracks, and precise ultrasonic testing for identifying internal flaws or discontinuities, ensuring the absolute structural integrity and reliability of every piece of ornamental cast iron.

The engineered design life of properly manufactured, correctly installed, and diligently maintained decorative cast iron products is truly exceptional, frequently extending well beyond 50 to 100 years, standing as a profound testament to the material's inherent durability, stability, and resistance to environmental degradation. This remarkable longevity contributes immeasurably to the overall sustainability profile of any project, significantly reducing the necessity for frequent replacements and thereby minimizing environmental impact throughout the product's entire lifecycle. Our decorative iron castings are engineered not merely for immediate aesthetic appeal but for enduring, consistent performance against a myriad of severe environmental stressors, including extreme temperature fluctuations, intense ultraviolet (UV) radiation, and aggressive corrosive agents. This unparalleled resilience is achieved through a synergistic combination of superior material selection, optimized casting processes that meticulously minimize internal stresses within the metal structure, and the application of advanced, multi-layered surface protection systems. For instance, hot-dip galvanization, applied with meticulous precision according to ASTM A123/A123M standards, provides a robust, metallurgically bonded layer of zinc onto the iron surface, offering unparalleled cathodic protection against rust, even if the primary surface coating experiences minor scratches or localized damage. This foundational layer is frequently complemented by a high-performance architectural powder coating, which adds an aesthetic, durable, and highly chip-resistant layer while further enhancing protection against abrasion, chemical exposure, and UV degradation. These meticulously engineered, multi-layered protective schemes are absolutely critical for successful applications in highly aggressive environments, such as coastal areas with persistent salt spray, industrial zones adjacent to petrochemical or metallurgical plants where airborne corrosives may be prevalent, or high-traffic urban settings characterized by elevated pollution levels.

Our continuous, proactive investment in advanced Research and Development (R&D) is keenly focused on continuously enhancing these sophisticated protective treatments and exploring innovative casting methodologies to further refine product performance, optimize material usage, and improve overall cost-efficiency. This includes meticulous evaluation of novel primer technologies, rigorous testing of the adhesion and long-term durability of various topcoats under accelerated weathering conditions, and ongoing optimization of casting designs for reduced material consumption without any compromise to structural integrity. By systematically testing our products in state-of-the-art accelerated weathering chambers and conducting real-world pilot installations, we gather invaluable empirical data that validates our precise design life predictions and facilitates the continuous refinement of our manufacturing protocols and material specifications. Our dedicated internal quality audit teams, coupled with periodic, independent third-party certifications and comprehensive factory audits, ensure that our quality control procedures remain at the absolute forefront of industry best practices. This meticulous, data-driven approach to quality assurance, synergized with our deep technical expertise and extensive service years garnered from decades in the highly specialized casting industry, instills profound trustworthiness in our product offerings. It serves as our guarantee that every single ornamental iron casting piece we meticulously produce and deliver is not merely a component, but a reliable, high-performance, and enduring asset designed to serve our clients' most critical long-term projects with unwavering integrity and aesthetic excellence.

Streamlined Logistics, Predictable Delivery Timelines, and Comprehensive Customer Support for Decorative Iron Castings

In the intricate and often time-sensitive landscape of B2B supply chains, particularly for bespoke or large-volume components like decorative iron castings, the efficiency of logistics and the reliability of delivery timelines are paramount, holding equal importance with the inherent quality of the product itself. We recognize acutely that project schedules are frequently constrained, and even minor delays can cascade into significant financial repercussions and operational disruptions for our clients. Consequently, our robust and highly optimized supply chain management system is meticulously engineered to ensure the punctual and secure delivery of our products to any destination worldwide. From the precise moment an order for decorative cast iron components is formally confirmed, our dedicated, expert logistics team assumes comprehensive coordination of every subsequent step. This encompasses detailed production scheduling to maximize efficiency, multi-stage quality inspections to maintain our rigorous standards, meticulous and secure packaging designed specifically to prevent any transit damage, streamlined customs clearance processes to navigate international trade regulations, and the strategic selection of optimal shipping routes. We cultivate strong, long-standing partnerships with highly reputable global freight forwarders and leading shipping lines, enabling us to offer a flexible array of transportation options, including both expedited air freight for urgent requirements and cost-effective sea freight for larger volumes, allowing clients to make choices based on their specific urgency and budgetary considerations. Typical delivery cycles for our standard decorative iron castings range from 4 to 6 weeks following definitive order confirmation, while more highly customized or exceptionally large-volume orders may necessitate a lead time of 8 to 12 weeks, contingent upon the intricate design complexity and current production queue demands. Throughout the entire transit process, we provide proactive, detailed shipping updates and real-time tracking information, thereby maintaining full transparency and keeping our clients thoroughly informed at every stage. This proactive communication minimizes uncertainties, mitigates potential risks, and significantly facilitates the seamless execution of their complex projects requiring ornamental iron casting.

Beyond the critical aspects of efficient logistics, our unwavering commitment to unparalleled client satisfaction extends through our comprehensive customer support infrastructure and robust warranty provisions. Each and every ornamental iron casting product that we meticulously manufacture is backed by a substantial and transparent warranty, typically covering material defects and manufacturing flaws for a generous period of 5 to 10 years, the precise duration often being dependent on the specific product type, the complexity of its application, and the environmental conditions of the installation site. This industry-leading warranty provides our valued clients with an invaluable sense of security and peace of mind, assuring them that their significant investment in high-quality decorative iron castings is rigorously protected for the long term. Our dedicated technical support team comprises highly experienced engineers and seasoned casting specialists who are readily available to provide expert, insightful guidance on optimal product selection, best-in-class installation methodologies, and proactive maintenance recommendations designed to maximize product longevity. Whether it involves assisting with the seamless integration of complex custom designs, adeptly troubleshooting unforeseen on-site issues, or providing comprehensive technical data sheets and detailed product specifications, our team is wholly committed to offering prompt, precise, and profoundly knowledgeable assistance to every client. Furthermore, we furnish detailed maintenance guides and long-term care instructions specifically tailored to preserve the aesthetic appeal and extend the functional service life of our decorative cast iron products, emphasizing proactive preservation strategies rather than reactive and costly repairs.

Our overarching customer support philosophy is meticulously built upon the fundamental pillars of responsiveness, proactive engagement, and absolute transparency. We diligently maintain open and accessible communication channels, including assigning dedicated account managers for large-scale projects, thereby ensuring that all client inquiries, technical challenges, and logistical considerations are addressed swiftly, thoroughly, and effectively. Regular and constructive feedback loops with our clients are integral to our operational ethos, enabling us to continuously refine and enhance our products, services, and overall client engagement processes, thereby fostering enduring and collaborative long-term relationships that transcend mere transactional interactions. For bespoke projects involving unique and intricate ornamental iron parts, our specialized project management team collaborates intimately with the client from the very initial conceptualization and detailed drawing phase, guiding them through meticulous prototyping, rigorous testing, and culminating in the precision final production, ensuring that all specifications are met with uncompromising accuracy. This deeply integrated approach, which seamlessly combines ultra-efficient logistics, comprehensive and proactive support, and clear, robust warranty terms, unequivocally underscores our unwavering dedication to delivering not just superior decorative iron castings, but also an exceptional, holistic, end-to-end client experience. This comprehensive commitment solidifies our standing as a trusted, reliable, and preferred partner for all B2B procurement needs in the global market for decorative iron castings.

Frequently Asked Questions (FAQs) about Decorative Iron Castings

Q1: What is the typical lifespan and maintenance requirement for decorative iron castings?

When meticulously manufactured to stringent quality standards, expertly installed, and adequately maintained with appropriate and high-performance surface treatments (such as hot-dip galvanization followed by advanced powder coating), decorative iron castings possess an exceptionally long operational lifespan, frequently extending well beyond 50 to 100 years. This remarkable longevity makes them a highly sustainable and economically advantageous long-term investment for a wide array of infrastructure, architectural, and heritage preservation projects. The primary factors influencing their durability include the specific grade of cast iron utilized (e.g., the robustness of ductile iron versus the fine detail capacity of gray iron), the inherent quality and precision of the initial casting process, the efficacy and integrity of the applied protective coatings against environmental aggressors like corrosion, UV radiation, and abrasion, and the specific environmental conditions of the installation site (e.g., coastal exposure, industrial atmosphere). Maintenance requirements are notably low due to the inherent durability of cast iron and the protective coatings. Typically, this involves periodic cleaning to remove accumulated dirt or debris, and potentially, the re-application of protective coatings after several decades, depending on wear and environmental severity. Proactive maintenance significantly extends their service life and preserves their aesthetic appeal, ensuring that your investment in ornamental iron casting continues to add value and beauty for generations.

Q2: How do you ensure the dimensional accuracy and superior surface finish for highly intricate ornamental designs in decorative iron castings?

Ensuring both precise dimensional accuracy and a superior surface finish for highly intricate ornamental iron castings involves a comprehensive, multi-pronged approach that begins at the very earliest stages of design and extends through to the final finishing. The process commences with the creation of ultra-precise patterns, often utilizing advanced CNC machining for complex geometries or cutting-edge 3D printing technologies for rapid prototyping and fine details, all meticulously checked against detailed CAD (Computer-Aided Design) blueprints. During the sand casting process, stringent control over sand compaction, moisture content, and mold assembly is absolutely crucial to achieve consistent results and minimize dimensional variations. For designs demanding exceptionally high fidelity to the original pattern, intricate details, or an ultra-smooth surface, the investment casting (lost wax) method is employed, known for its superior precision. Post-casting, processes like rigorous shot blasting or sandblasting are meticulously performed to thoroughly clean the casting's surface, remove any residual scale or molding material, and achieve a uniform texture that is ideal for subsequent protective finishes. For critical dimensions or specific functional interfaces, precision CNC machining may be integrated for secondary operations such as drilling, tapping, or milling. Throughout these stages, we implement strict, multi-point quality control procedures, including detailed visual inspections for aesthetic defects, precise dimensional checks using highly calibrated instruments and jigs, and occasional advanced 3D scanning to verify complex geometries. This meticulous adherence to quality at every step ensures that every ornamental cast iron part not only meets but demonstrably exceeds specified tolerances and desired surface finish requirements, satisfying both functional and aesthetic expectations.

Q3: Can decorative iron castings be fully customized to meet specific, unique project requirements?

Absolutely. Customization is not merely an option but a core competency and a significant strength of our offerings in decorative iron castings. We specialize in providing highly bespoke solutions, engaging in close, collaborative partnerships with architects, design firms, urban planners, and project managers to precisely translate their unique visions into tangible, high-quality cast iron realities. Our extensive customization capabilities encompass a broad spectrum of requirements: this includes the creation of entirely unique artistic designs and intricate patterns (for instance, incorporating specific corporate logos, historical crests, or bespoke decorative motifs for an ornamental cast iron fence or gate system), accommodating highly specific dimensions and sizes to ensure seamless integration with existing structures or unique architectural elements, the meticulous selection of particular cast iron grades (such as specifying gray iron for its superior detail reproduction or ductile iron for applications requiring higher strength and ductility), and an extensive range of sophisticated surface finishes. These finishes can include precise color matching to specific RAL or Pantone codes for durable powder coatings, various textural finishes, or specialized anti-corrosion treatments tailored for exceptionally aggressive environments like coastal areas or industrial atmospheres. Our dedicated in-house design and engineering teams leverage state-of-the-art software for both design and simulation, guaranteeing that every custom ornamental iron casting component is optimized for both its aesthetic appeal and its structural soundness, ensuring full compliance with your project's exacting specifications and long-term performance objectives.

Q4: What are the primary advantages of utilizing cast iron compared to other common materials like steel for decorative architectural elements?

While steel undoubtedly offers significant advantages in terms of high tensile strength and superior ductility, cast iron presents distinct and often superior advantages for numerous decorative and structural architectural applications, primarily due to its inherent casting properties and unique material characteristics. A paramount advantage of cast iron, particularly gray iron, is its unparalleled castability, which allows for the creation of incredibly intricate, fine, and complex details that are either extremely difficult, prohibitively expensive, or entirely impossible to achieve through steel fabrication processes like welding, cutting, or bending. Cast iron also boasts exceptional compressive strength and inherent rigidity, making it an ideal choice for static, load-bearing architectural elements such as columns, bases, and balustrades where resistance to compression and deformation under load is critical. Furthermore, cast iron exhibits superior vibration damping capacity, which can be a valuable characteristic in applications where acoustic or mechanical vibrations need to be minimized. The ability to incorporate complex, hollow sections or varied wall thicknesses directly during the casting process can also lead to significant material savings and optimized weight distribution without compromising structural integrity. For exterior and exposed applications, when paired with appropriate, high-performance surface treatments such as hot-dip galvanization and advanced powder coating, decorative iron castings provide outstanding long-term corrosion resistance and require minimal maintenance, offering a superior blend of aesthetic versatility, enduring durability, and overall lifecycle cost-effectiveness when compared to many fabricated steel alternatives. This combination makes decorative iron castings a strategic and aesthetically compelling choice for projects demanding both beauty and longevity.

Conclusion: The Enduring Value and Future Outlook of Decorative Iron Castings in Modern Construction

The exhaustive journey through the intricate and highly specialized world of decorative iron castings unequivocally reveals a compelling and harmonious blend of profound artistic heritage, timeless craftsmanship, and cutting-edge modern engineering prowess. From their foundational and indispensable role in significantly enhancing both the aesthetic appeal and the structural integrity of diverse urban landscapes, historical structures, and private architectural masterpieces, to their increasingly vital and specialized contributions in demanding industrial applications, ornamental iron castings consistently deliver unparalleled durability, remarkable aesthetic versatility, and a demonstrable long-term cost-effectiveness that sets them apart. The meticulous manufacturing processes employed, encompassing precise and intricate pattern making, advanced and optimized casting techniques, and comprehensive, multi-stage post-casting treatments, are all rigorously executed to ensure that each individual component not only meets but consistently exceeds stringent international industry standards for mechanical properties, dimensional accuracy, and critical surface finish. Our unwavering commitment to uncompromising quality assurance, rigorously backed by international certifications such as ISO 9001:2015 and a robust regimen of exhaustive testing protocols, serves as a powerful guarantee of the exceptional reliability and extended service life that discerning B2B clients demand for their most critical and high-profile projects. As compellingly demonstrated by our diverse portfolio of successful application cases and the unwavering testimonials from satisfied clients, investing in expertly produced, high-quality decorative iron castings translates into tangible, measurable benefits: significantly reduced long-term maintenance overheads, dramatically enhanced structural integrity, and the timeless, classical beauty that only meticulously crafted cast iron can enduringly provide to any architectural or urban development.

The market for ornamental iron casting is strategically positioned for sustained and robust growth, propelled by prevailing global trends in sustainable construction practices, extensive urban revitalization initiatives, and an ever-increasing appreciation for enduring, high-quality architectural elements that contribute both functionality and character. As a leading and specialized manufacturer in this sophisticated domain, our unwavering dedication to continuous innovation, highly agile customization capabilities, and comprehensive end-to-end client support collectively positions us as the ideal and most trusted partner for your next significant project involving decorative iron castings. We possess a profound understanding of the complex and delicate interplay between ambitious aesthetic visions and precise technical requirements, enabling us to offer bespoke solutions that range from uniquely designed decorative cast iron post collar units to large-scale, intricate ornamental iron fence systems. Our transparent and efficient logistics framework, clearly articulated warranty terms, and readily accessible technical support infrastructure further underscore our unwavering commitment to fostering a seamless, reliable, and profoundly trustworthy partnership. By strategically choosing expertly produced decorative iron castings from a reputable manufacturer, you are not merely acquiring a product; you are making a strategic investment in a legacy of enduring strength, timeless beauty, and environmental sustainability that will profoundly enrich environments and serve communities for generations to come. We sincerely invite you to explore our extensive and diverse range of products and to leverage our unparalleled expertise to seamlessly transform your conceptual designs and challenging project requirements into tangible, enduring realities of exceptional quality and aesthetic distinction.

For further in-depth technical insights into the multifaceted properties, advanced manufacturing processes, and diverse applications of cast iron, we highly recommend consulting authoritative industry publications and peer-reviewed academic journals that specialize in metallurgy and materials engineering. These resources offer comprehensive research, empirical data, and expert analyses that can further inform B2B decision-making. One such invaluable resource is the "Journal of Materials Science and Technology," which frequently publishes cutting-edge research on advanced ferrous alloys and their specific applications across various industries. Another highly respected and authoritative source is the "International Journal of Metalcasting," a premier peer-reviewed journal jointly published by the American Foundry Society (AFS) and the World Foundry Organization (WFO), providing profound insights into state-of-the-art casting processes, material science developments, and industry best practices relevant to decorative iron castings and beyond.

References:

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters