Premium Sliding Window Rollers: Smooth & Durable Glide

Main Keywords: sliding window roller, roller door rollers, sliding door track rollers, sliding door rollers

1. Industry Overview & Market Trends

The sliding window roller family—encompassing roller door rollers, sliding door track rollers, and sliding door rollers—is at the core of modern architectural movement systems. Driven by surging demands in smart infrastructure, energy-efficient buildings, and heavy-industry automation, the market for these rollers is forecasted to grow at a CAGR of 6.2% from 2023 to 2028 (MarketsandMarkets, 2023).

- Asia-Pacific: Fastest growth due to construction and public infrastructure boom.

- OEMs & EPCs: Demand for highly durable, low-maintenance, and precision components.

- Composite & Stainless Materials: Accelerated adoption in corrosive and outdoor applications.

2. Technical Data & Product Specification Visuals

To meet the requirements of distinct industries, each sliding window roller features tightly controlled dimensions, advanced surface treatment, and precise bearing integration.

| Product Type | Picture | Material | Diameter (mm) | Load Capacity (kg) | Finish | Industry Standard |

|---|---|---|---|---|---|---|

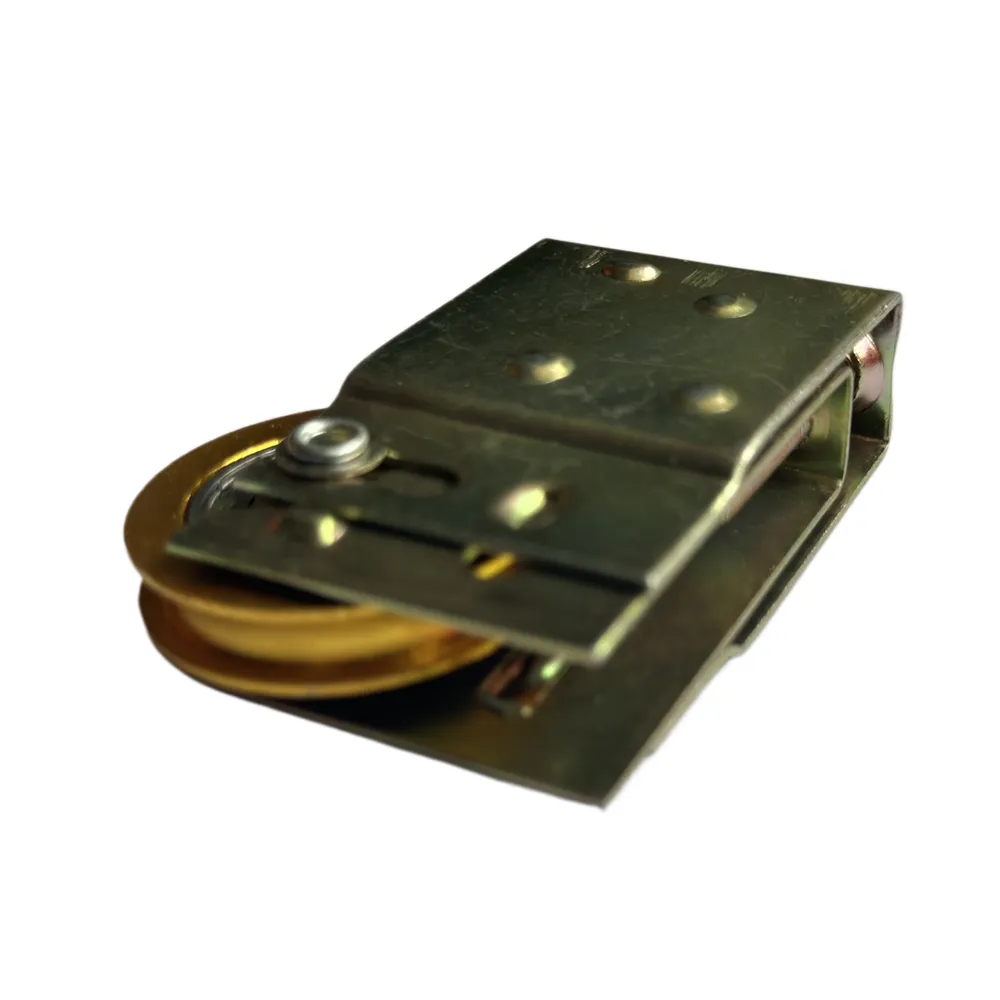

| Sliding Window Roller |

|

Stainless Steel/Alloy Carbon | 23–72 | 80–350 | Mirror Zinc/Chrome | ISO 9001:2015 |

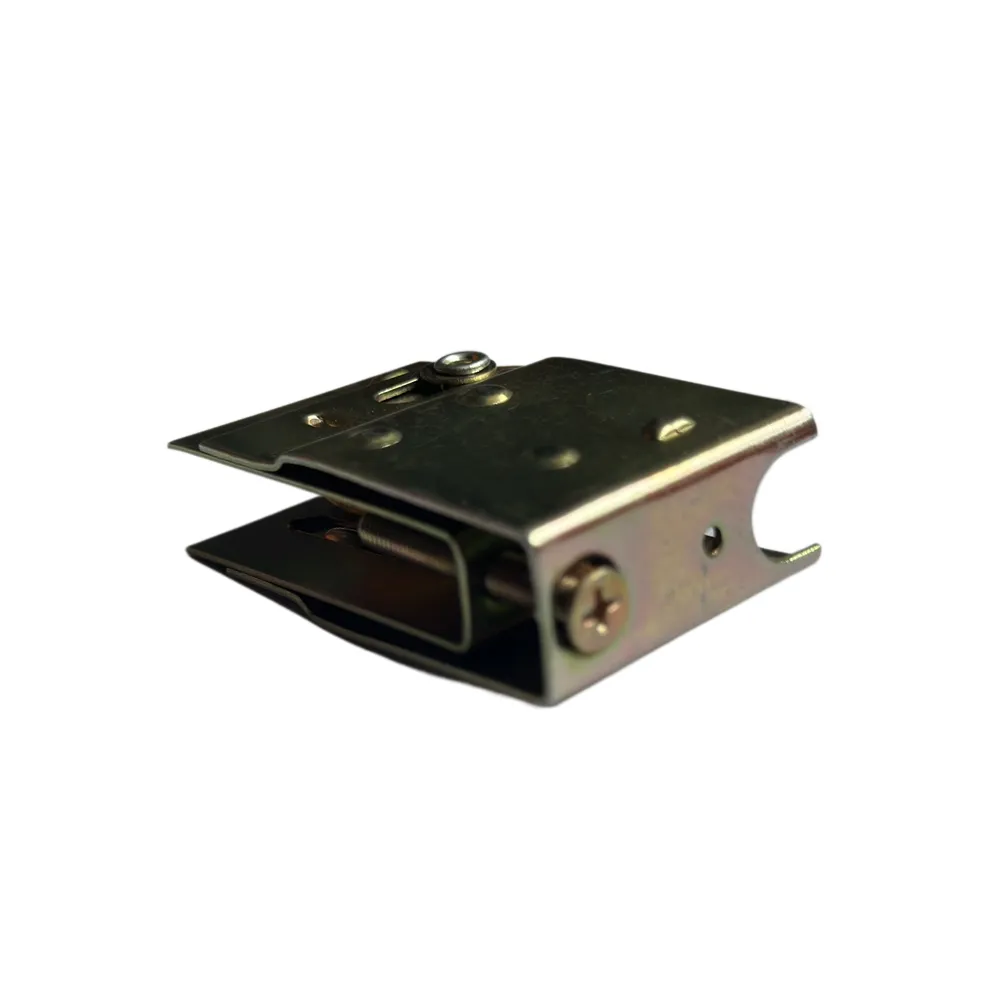

| Roller Door Rollers |

|

Galvanized Iron | 32–76 | 110–580 | Electroplated | ANSI/BHMA A156.14 |

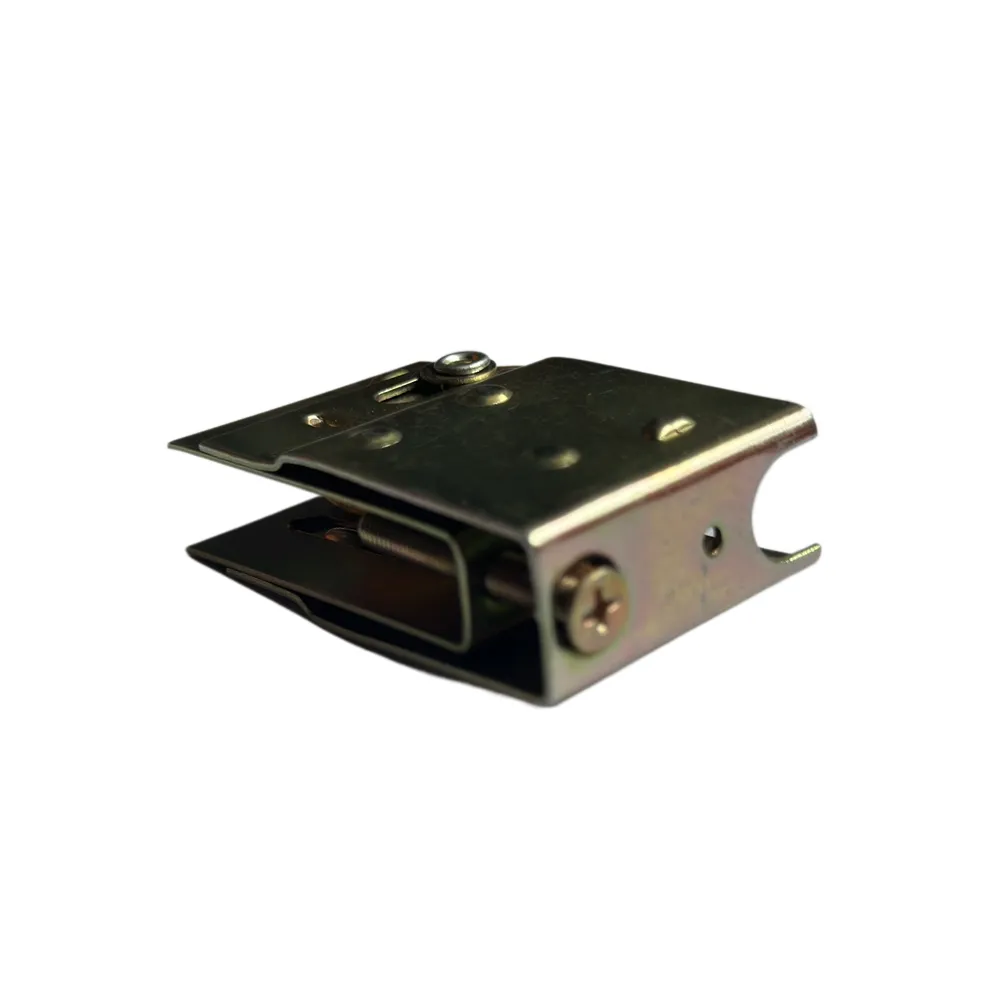

| Sliding Door Track Rollers |

|

Carbon Steel, Nylon Composite | 40–85 | 90–700 | HDG/Black Oxide | ISO 2768, EN 1527 |

3. Manufacturing Process Unveiled

-

Raw Material Selection

Utilizing premium alloy steel, stainless steel, or engineered nylon—graded to meet ISO 683 metallurgical purity standards. -

Precision Casting/Die Forging

Components are precision-cast or drop-forged for maximum structural integrity and uniform grain. -

CNC Finishing

High-speed CNC machines apply meticulous tolerances (IT7–IT10 range) and provide surface roughness Ra ≤ 0.8μm. -

Surface Treatment

Finished parts undergo zinc/chrome plating, HDG, or anodizing as per ASTM B633/ISO 4042 for >500 hours salt spray life. -

Bearing Assembly

POM/steel bearings press-fitted for ultra-smooth movement, FSQ-checked for run-out ≤ 0.03mm. -

Final QC & Certification

Every sliding window roller is tested to load, concentricity and lifecycle >130,000 cycles (DIN EN 1527 standard).

- Material Cert: All batches traceable, 100% PMI (Positive Material Identification).

- Quality: ISO 9001:2015, ongoing PPAP Level 3 validation for automotive/OEM partners.

- Longevity: Designed for minimum 100,000 cycles @ rated load.

- Corrosion Resistance: Salt spray ≥ 500h (ASTM B117); options for double-sealed bearings.

- Customization: OEM/ODM logo, packaging & technical parameters to client spec.

4. Performance Data Visualization

5. Manufacturer Comparison: Data-Driven Table

| Manufacturer | Main Product | Material Options | Certification | Global Partner | Lead Time (days) |

|---|---|---|---|---|---|

| TIJ Iron Casting (China) | Sliding Roller | Stainless, Carbon Steel, Nylon | ISO 9001, SGS | Sinopec, ABB | 7–25 |

| Dorma Kaba (DE/CH) | Sliding Door Rollers | Steel, Aluminum | CE, ISO 9001 | Siemens, Lendlease | 14–45 |

| Hettich (Germany) | Roller Door Rollers | Stainless, ABS | ISO 14001 | Hafele, IKEA | 10–32 |

| Stanley (USA) | Sliding Window Roller | Zinc-plated Steel | ANSI/BHMA | GE, Ford | 18–60 |

6. Custom Engineering & Application Excellence

Popular Segments: Heavy-duty telescopic sliding window roller for metallurgy, corrosion-proof sliding door rollers for marine/offshore, self-lubricating roller for petrochemical pipelines.

Case Study: Petrochemical Facility, Singapore

- Issue: Standard steel rollers failed after 18 months due to chloride vapor corrosion.

- Solution: TIJ Iron supplied duplex stainless sliding window rollers (ISO 9227/ASTM G85 tested), life >5 years maintenance-free.

- Result: Maintenance downtime reduced 80%, TCO savings ~USD 16,000 p.a.; see client testimonial (details).

Case Study: Metro Rail Station, India

- Customization: Fire-certified sliding door rollers with double-shielded deep groove bearings (EN 45545 compliant).

- Outcome: Zero failure in 1.2M cycles; station access reliability >99.98%.

7. Typical Application Scenarios

- Commercial Architecture: Sliding façade/wall systems, energy-saving window solutions.

- Industrial Plants: Heavy machinery doors, automation rail guides using sliding window roller for precise alignment.

- Water Treatment: Sliding window rollers in corrosion-prone clarifier mechanisms.

- Metro & Railway: Platform barrier/partition doors, emergency egress systems.

- Marine & Offshore: Salt-resistant, self-lubricating sliding door rollers.

8. Quality, Certification & Testing

Testing:

- Salt Spray Test: ASTM B117 ≥ 500h

- Wear Resistance: ≤0.2 mm loss after 120K cycles @rated load

- Dynamic Run-out: ≤0.03 mm

- Cert Traceability: All batches traceable to melt number; third-party reports available

9. Delivery, Warranty & Customer Support Details

- Lead Time: Standard 7–25 days ex works (custom projects depend on order volume and process complexity).

- Warranty: 2-5 years (app-configurable), includes replacement for premature wear/defect.

- Support: 24/7 email & hotline support; free pre-sales technical consulting; on-site installation support for major OEM partners.

- Spare Parts: Stocked for major components; fast-ship within 4–7 business days.

- Documentation: Full COA, COC, test reports; RoHS/REACH upon request.

10. FAQ About Sliding Window Rollers & Related Products

- 1. What are the standard materials used in making sliding window roller?

- Typical materials include stainless steel (304/316) for corrosion-prone environments, carbon alloy steel for high load, and reinforced nylon composites for quiet and lightweight applications.

- 2. How do I select the correct specification for my roller door rollers?

- Match load rating, ambient conditions (humidity/chemicals), groove profile (U/V), and required certifications (ISO/ANSI). For high frequency or public safety, request manufacturers’ cycle test data and compliance certificates.

- 3. Which standards govern the design and safety of sliding door track rollers?

- Key standards include ISO 9001 (quality), EN 1527 (function & endurance), ANSI/BHMA A156.14 (USA doors), and optional ROHS/REACH for eco compliance.

- 4. How is a sliding window roller installed and maintained?

- Installation generally follows OEM mounting diagrams (supplied). Maintenance requires periodic cleaning, lubrication (if steel), or check for debris/track distortion for all types. Replacement cycle: every 3–7 years depending on application.

- 5. What is the typical service life of a high-end sliding window roller?

- Under standard load and conditions, quality sliding window roller products last 100,000-200,000 operational cycles, translating to 5–8 years in industrial use, per EN 1527 test protocols.

- 6. Can I order custom-designed sliding door rollers for a unique application?

- Yes. Provide blueprints or working sketches; manufacturers can accommodate groove/track profiles, coating colors, bearing types, and branding. OEM/ODM services are standard for bulk orders.

- 7. Which certifications should I request for safety-critical environments?

- For transport, pharma, or fire-resistance contexts: EN 1527, ISO 9001, CE Marking, and optionally UL, FDA (food equipment).

11. Conclusion: The Future of Sliding Window Roller Technology

As buildings and industrial solutions become ever more demanding, investment in high-precision, certified sliding window roller technology will define the next benchmarks for reliability and operational efficiency. Competition will revolve around smart material integration, longer service cycles, and environmental certifications.

Embrace data-driven purchasing—demand lifecycle test proofs, certifications, and transparent manufacturer credentials for every sliding window roller or sliding door rollers project.

- ISO.org: ISO 9001:2015 Quality Management Systems

- EN 1527: Sliding Doors and Partition Systems (BS EN 1527:2019)

- MarketsandMarkets: Global Building Hardware Market Insights

- HardwareSource Forum: Door and Window Hardware Discussions

- Door & Hardware Journal: Industry Innovations, Testing & Safety

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters