Sliding Wheel Cost Analysis for Optimal Purchasing Decisions

Understanding the Pricing of Sliding Wheels A Comprehensive Overview

In the world of machinery and equipment, the sliding wheel is a critical component that often gets overlooked. Yet, it plays a significant role in a wide range of applications, from manufacturing systems to everyday consumer products. Understanding the pricing of sliding wheels involves exploring various factors that influence their costs, the materials used in their fabrication, the type of applications they serve, and the market dynamics that govern their availability.

The Basics of Sliding Wheels

Sliding wheels are designed to facilitate movement by reducing friction between surfaces. They are commonly found in applications such as conveyor belts, carts, and various machinery. The functionality of these wheels is largely determined by their design, materials, and construction methods. The quality of a sliding wheel can greatly affect the efficiency and longevity of the equipment in which it is used.

Factors Influencing Pricing

1. Material Composition The type of material used to manufacture sliding wheels plays a crucial role in determining their price. Common materials include plastic, metal, rubber, and various composites. For instance, wheels made from high-density polyethylene tend to be more affordable, while those crafted from durable metals like aluminum or steel can be considerably pricier due to their enhanced strength and longevity.

2. Design Specifications The complexity of the wheel's design can also affect its price. More intricate designs that include features like bearings, custom sizes, or specialized tread patterns require more advanced manufacturing processes and expertise, leading to higher costs. In contrast, standard, off-the-shelf options tend to be more economical.

3. Volume and Demand Pricing is significantly influenced by market demand and production volume. In scenarios where sliding wheels are produced in bulk, economies of scale can reduce manufacturing costs, enabling manufacturers to offer competitive pricing. Conversely, niche applications with lower demand may result in higher prices due to limited production runs.

4. Brand Reputation Established brands that have built a reputation for quality and reliability often command higher prices. Clients in industries where safety and durability are paramount may be willing to pay a premium for well-known brands to ensure they receive a product that meets stringent quality standards.

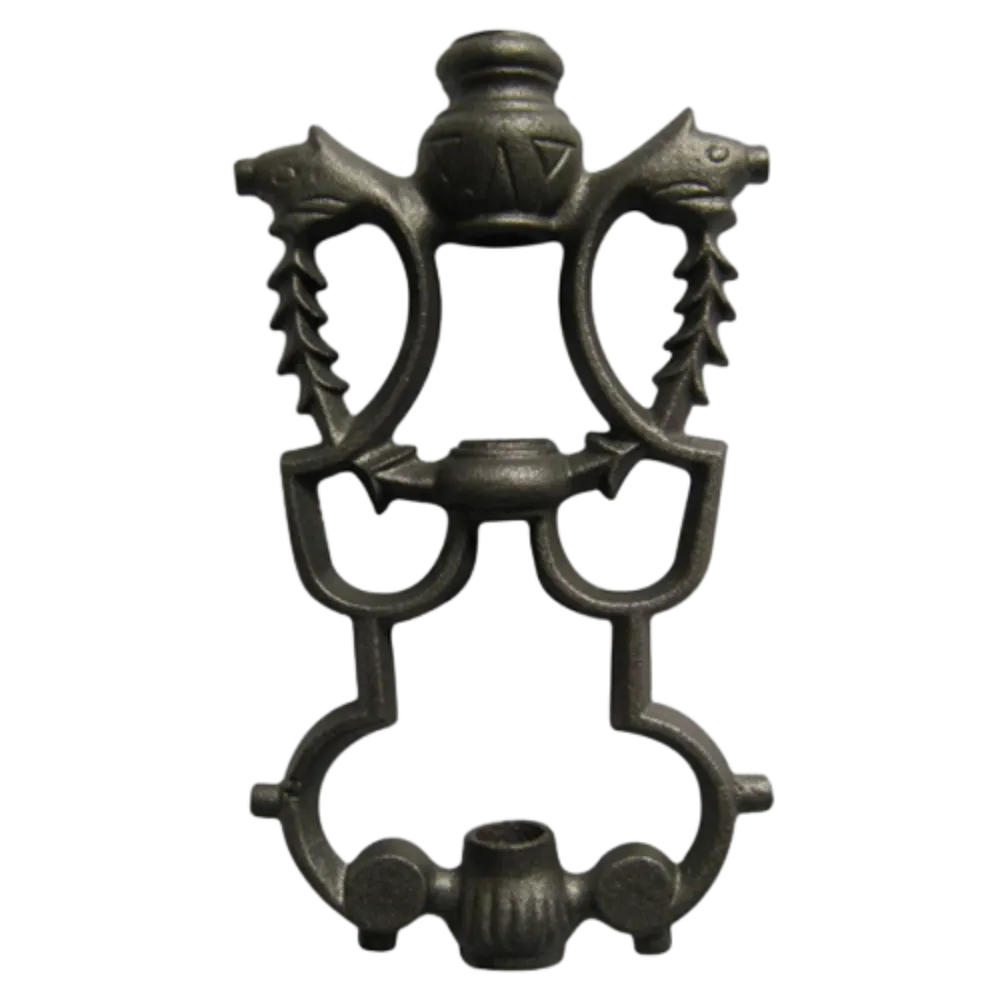

sliding wheel price

5. Customization and Specialization Many industries require specialized sliding wheels tailored to specific applications. Customization can significantly increase the cost due to the additional design and manufacturing processes involved. Businesses aiming to optimize performance or meet unique operational needs may choose to invest in these specialized solutions.

Comparative Pricing Analysis

To get a clearer picture of sliding wheel pricing, it’s useful to conduct a comparative analysis. For instance, standard polypropylene sliding wheels may cost around $1-$5 each in bulk orders, while heavy-duty stainless steel wheels can range from $15 to $50 or more per unit, depending on size and load capacity. In specialized applications, such as aerospace or medical equipment, prices can soar significantly higher, easily reaching hundreds of dollars due to the stringent regulatory requirements and performance standards.

Market Trends

The sliding wheel market is subject to various trends that can impact pricing. The rise of automation in manufacturing, for instance, has increased the demand for high-quality, durable sliding wheels that can withstand continuous operation. Additionally, advancements in materials technology have led to the introduction of wheels that offer enhanced performance, albeit often at a higher price point.

Environmental considerations are also becoming a significant factor. Manufacturers are increasingly focusing on sustainable practices, leading to a rise in demand for eco-friendly materials. While this shift is positive for the environment, it may also lead to increased costs as companies invest in research and development for sustainable products.

Conclusion

In conclusion, the pricing of sliding wheels is a multifaceted issue influenced by various factors such as material composition, design specifications, market demand, and customization. Understanding these dynamics can help businesses make informed purchasing decisions, ensuring they select the right product for their needs without overspending. As the market continues to evolve, staying updated on trends and innovations will be crucial for both manufacturers and consumers to optimize their operations and investments in sliding wheel technology.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters