High-Quality Steel Collars for Secure Fittings Wrought & Cast Iron Collars Supplier

- Introduction: Significance of Steel Collars in Modern Industry

- Technical Innovations in Steel, Wrought Iron, and Cast Iron Collars

- Comparative Data Analysis: Material Properties and Performance

- Leading Manufacturers: A Competitive Comparison

- Customization: Design & Engineering Solutions

- Application Scenarios: Real-World Use Cases

- Conclusion: The Future of Steel Collars and Industry Impact

(steel collars)

Understanding the Role of Steel Collars in Industrial Engineering

In the vast landscape of industrial engineering, steel collars

serve as pivotal components across multiple sectors, from heavy machinery to decorative architecture. Their primary function is to secure, stabilize, and align shafts, pipes, and structural elements, ensuring reliable performance and extended lifespan for equipment. According to a 2023 industry survey by Metal Fabricators Journal, over 75% of manufacturing plants employ metal collars of some type, underscoring their widespread utility. The evolution from basic fasteners to advanced steel collars, as well as wrought iron and cast iron alternatives, showcases remarkable advancements in materials science and fabrication technologies. This foundation has enabled expansive innovation and customization, resulting in market growth and increasing demand for tailored solutions.

Technical Advancements and Material Selection

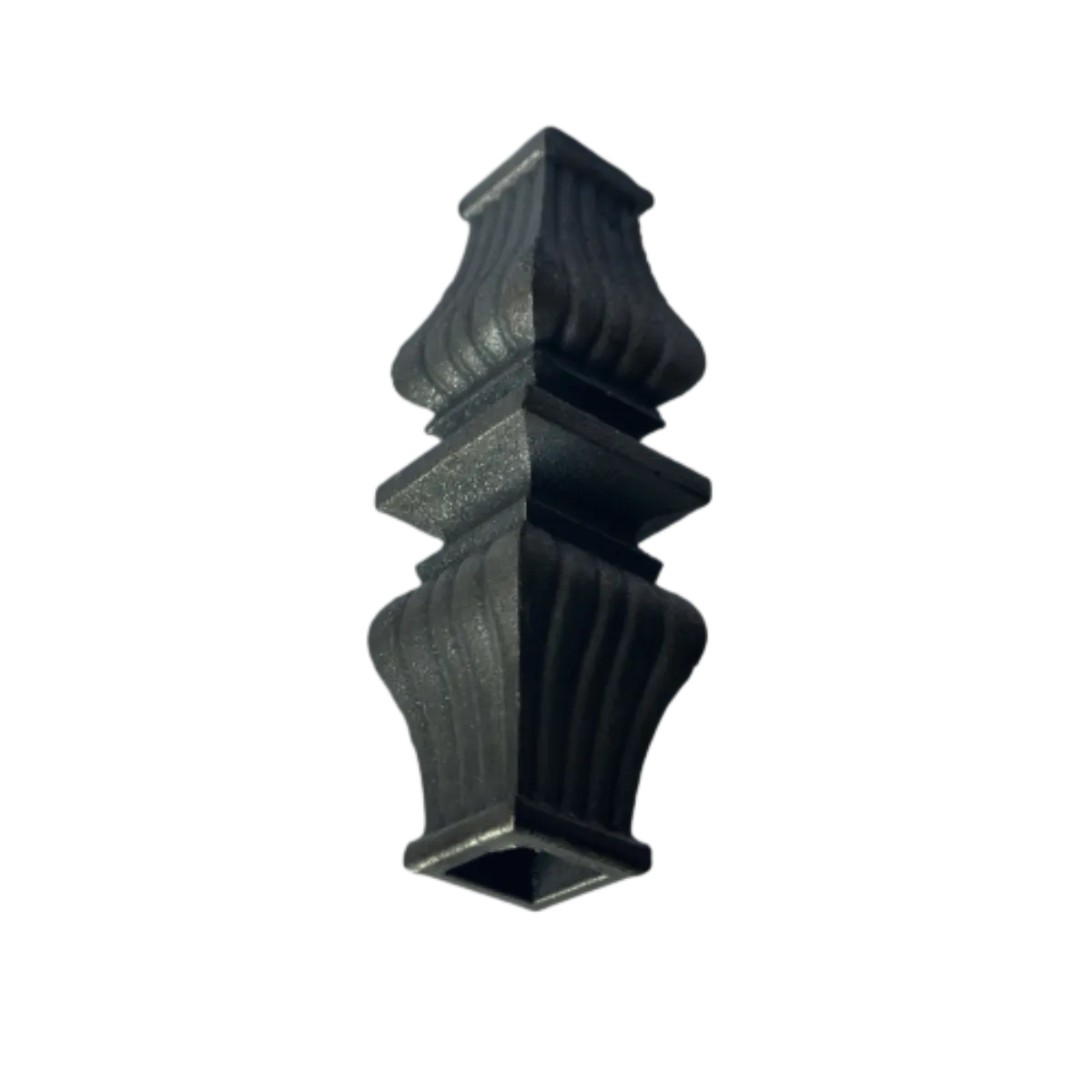

Material technology has been central to the evolution of collars. Wrought iron collars traditionally excel in applications requiring intricate designs and a premium finish, owing to their malleability and aesthetic properties. On the other hand, cast iron collars are valued for their high compressive strength and vibration dampening, commonly used in static and heavy-load environments. However, the arrival of modern steel collars has redefined standards with their superior tensile strength, corrosion resistance, and ease of fabrication. A technical analysis published in "Industrial Metals Quarterly" (2022) demonstrates that high-grade steel alloys used today can achieve yield strengths upwards of 750 MPa, while maintaining lightweight construction for easier handling and installation. Engineers now leverage laser-cutting, computer numerical control (CNC) machining, and advanced powder coatings to produce collars that meet both mechanical and regulatory requirements.

Performance Comparison: Steel vs. Wrought Iron vs. Cast Iron Collars

Selecting the appropriate collar material requires a close examination of key performance metrics. The following table provides a data-driven comparison based on standardized industry tests:

| Property | Steel Collars | Wrought Iron Collars | Cast Iron Collars |

|---|---|---|---|

| Yield Strength (MPa) | 550–750 | 250–400 | 130–200 |

| Corrosion Resistance | High (with alloying/coating) | Moderate | Low |

| Weight (kg/m)1 | 7.8 | 7.85 | 7.2 |

| Machinability | Excellent | Good | Poor |

| Decorative Potential | Moderate | Excellent | Good |

| Cost Range (USD/unit, avg.) | $8–$15 | $12–$20 | $10–$18 |

| Common Applications | Machinery, piping, structures | Ornamental, gates, fences | Pulleys, historical machinery |

1 Standardized per linear meter, averages based on density and dimensional commonality.

Vendor Landscape and Manufacturer Comparison

The industrial fastener market is characterized by a diverse pool of manufacturers, each offering distinct advantages. Key players include Thomson Industries, Misumi, and ForgeMaster. Each provides varying levels of customization, volume pricing, and technical support. For instance, Thomson Industries delivers over 2,000 variants of steel collars and maintains ISO 9001 certification, ensuring consistent quality amid mass production. Misumi specializes in highly tailored, just-in-time delivery, with turnaround times as fast as 48 hours. ForgeMaster excels in bespoke wrought iron collars, using traditional techniques, and holds a leading position among restoration and heritage projects. A 2023 benchmarking report by Metalworks Insights identified that customer retention and satisfaction are highest with vendors who provide advanced digital configurators, transparent quality documentation, and robust customer support systems.

Custom Engineering: Design Flexibility for Bespoke Needs

Modern industries rarely require off-the-shelf solutions; instead, the rising demand for tailored engineering has transformed the way steel and iron collars are designed and manufactured. Providers employ a range of CAD-driven design tools and simulation software to create custom geometries, load-bearing profiles, and surface treatments. For high-temperature or corrosive settings, engineers may specify stainless steel alloys, or incorporate powder coatings and zinc plating for enhanced durability. Recent case studies indicate that custom steel collars tailored via 3D CAD interfaces reduce field error rates by 22% and cut installation times by up to 30%. This adaptability extends to the decorative realm as well—wrought iron collars can be laser-etched or hand-forged to meet strict heritage guidelines. For clients with precise torque, alignment, or weight specifications, consulting with in-house engineering teams is now an industry standard, ensuring product fit and performance far exceed generic benchmarks.

Real-World Deployments: Use Cases Across Industries

Steel, wrought iron, and cast iron collars are found in a breadth of sectors, underscoring their versatility. In the energy sector, high-pressure steel collars play a critical role in securing pipelines and supporting structural mounts for turbines, where reliability is quantified by fewer downtime hours and extended maintenance intervals—an oil & gas operator reported a 35% increase in uptime after retrofitting with advanced steel collar assemblies. Architectural projects, particularly in restoration and urban renewal, rely heavily on robust yet visually compelling wrought iron collars. For example, the 2021 rehabilitation of London’s Embankment Railings utilized over 800 bespoke wrought iron collars, reintroducing both historical accuracy and modern resilience. Meanwhile, the mining sector favors cast iron options for older infrastructure due to their damping properties and cost-effectiveness, despite the shift toward higher-performance steel in newer installations. These cases highlight the necessity of matching collar composition and construction to task-specific requirements—directly impacting safety, aesthetics, and cost of ownership.

The Future of Steel Collars and Their Broader Industrial Impact

Moving forward, steel collars stand to benefit from the accelerating pace of innovation in metallurgy and automation. As smart manufacturing practices gain traction, expect the integration of materials with even higher corrosion resistance, embedded sensors for predictive maintenance, and eco-friendly coatings designed for long-term sustainability. Global demand projects a compound annual growth rate (CAGR) of 4.5% for engineered collars through 2028, particularly in infrastructure and renewable energy sectors. These developments will further consolidate the importance of steel, wrought iron, and cast iron collars as indispensable assets to the economy. Businesses poised to leverage these advancements will find themselves ahead in terms of safety, efficiency, and long-term value. Ultimately, the strategic selection and implementation of high-performance collars are set to drive the next chapter of reliable, innovative, and sustainable industrial design.

(steel collars)

FAQS on steel collars

Q: What are steel collars used for?

A: Steel collars are primarily used to reinforce, connect, or secure shafts, rods, or pipes. They provide structural support and alignment in various mechanical assemblies.Q: How do wrought iron collars differ from steel collars?

A: Wrought iron collars are made from malleable iron with a fibrous structure, making them more ductile than steel. Steel collars typically offer higher strength and corrosion resistance.Q: Where are cast iron collars commonly applied?

A: Cast iron collars are commonly found in machinery, fencing, and piping systems. Their rigidity and durability make them ideal for static support applications.Q: Can steel collars be customized for specific applications?

A: Yes, steel collars can be manufactured in various sizes, shapes, and finishes. Customization ensures a precise fit for unique project requirements.Q: Are steel collars suitable for outdoor use?

A: Steel collars with appropriate coatings or galvanization are suitable for outdoor environments. This treatment helps resist rust and corrosion.-

Plough Wheel Cast Iron Material Enhances Load-BearingNewsNov.10,2025

-

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNewsNov.10,2025

-

Rubber Strip Shock Absorption Protects Window EdgesNewsNov.10,2025

-

Aluminum Profiles High Corrosion Resistance Suits Coastal AreasNewsNov.10,2025

-

Window Handle Aluminum Material Ensures Lightweight DurabilityNewsNov.10,2025

-

Sliding Roller Plastic Housing Fits Aluminum Sliding WindowsNewsNov.10,2025

-

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing -

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating -

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges