varf forjat

Understanding Varf Forjat A Glimpse into Forged Steel and Its Applications

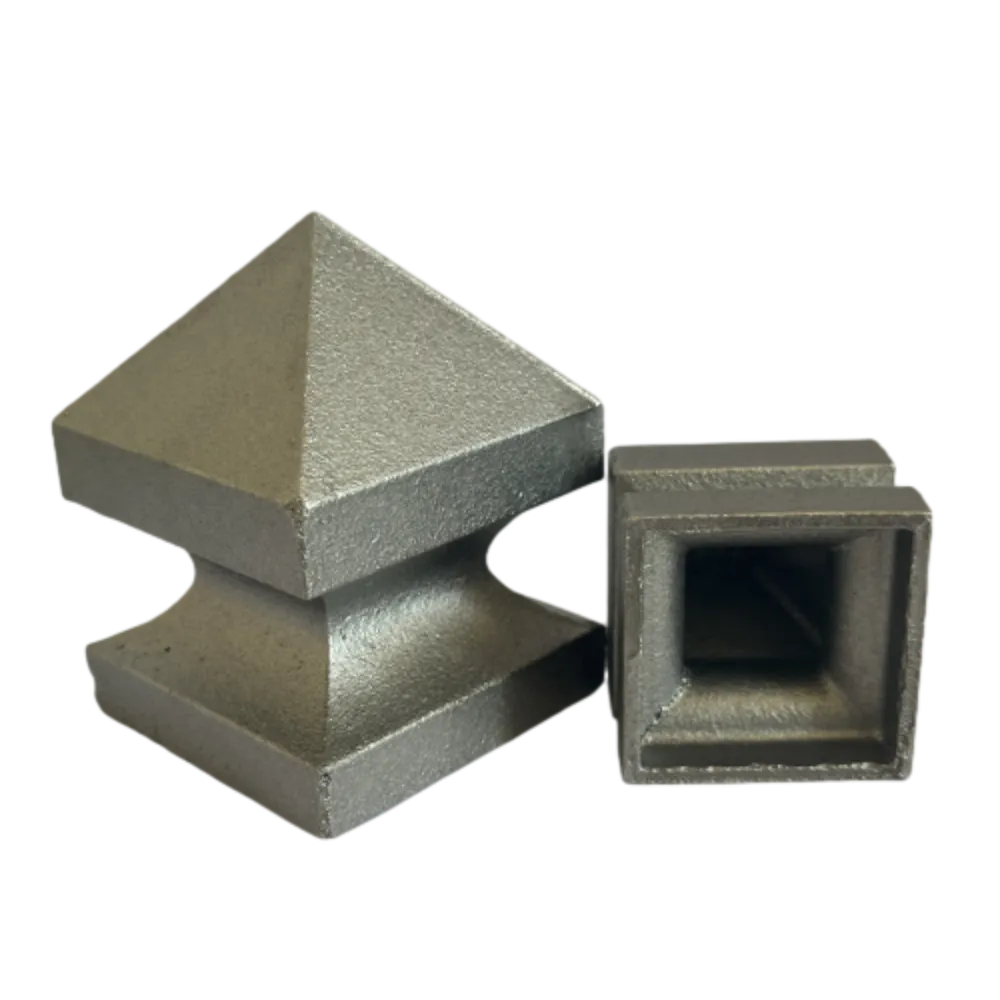

In the realm of metallurgy and industrial manufacturing, the term varf forjat which translates to forged steel in English, holds significant importance. Forged steel is a form of metalworking that involves the deformation of metal into desired shapes through the application of compressive forces. This process not only enhances the mechanical properties of steel but also expands its applications in various industries. This article delves into the characteristics, advantages, production processes, and common uses of forged steel.

Characteristics of Forged Steel

Forged steel is renowned for its superior strength and durability compared to other forms of steel. The forging process encourages grain refinement, which significantly enhances the mechanical properties of the steel. This results in greater tensile strength, increased impact resistance, and excellent fatigue resistance. The controlled deforming process reduces the likelihood of defects, ensuring that the finished product is more uniform in structure and performance.

Another defining characteristic of forged steel is its ability to withstand high pressures and temperatures. This makes it particularly suitable for use in high-stress environments where reliability is paramount. Additionally, the forging process can create complex shapes and intricate designs, allowing for versatility in applications across different sectors.

Advantages of Forged Steel

There are several advantages to using forged steel over cast or machined steel. First and foremost is its strength. The forging process aligns the grain structure of the steel, resulting in improved mechanical properties. This enhanced strength-to-weight ratio allows for the use of lighter components without compromising on performance.

Furthermore, forged steel exhibits superior toughness and ductility, enabling it to absorb impact without cracking. This is particularly beneficial in applications where sudden loads or shocks may occur. In addition, because forged components are less susceptible to defects and stress concentrations, they often offer greater longevity under operational conditions.

The cost-effectiveness of forged steel is another significant advantage. While the upfront tooling and production costs may be higher, the reduced failure rates and improved durability lead to lower lifecycle costs. Users can benefit from fewer replacements and maintenance efforts, ultimately leading to cost savings in the long term.

varf forjat

Production Process of Forged Steel

The production of forged steel typically involves several key steps, which can vary depending on the specific requirements of the final product. The process begins with the selection of the appropriate steel grade. Common materials used include carbon steel, alloy steel, and stainless steel.

Once the raw material is selected, it is heated to a suitable temperature to soften the metal—this is known as the forging temperature. The heated metal is then shaped using various forging methods, including open-die forging, closed-die forging, and ring rolling, to achieve the desired shape and dimensions. Each method offers unique advantages and is chosen based on the specific requirements of the component being produced.

After forging, the components may undergo additional processes such as heat treatment, machining, and surface finishing to enhance their properties and prepare them for final use. Heat treatment can further improve strength and hardness, making the forged pieces suitable for demanding applications.

Applications of Forged Steel

The applications of forged steel are extensive and varied, making it an integral component across multiple industries. In the automotive sector, forged steel parts are commonly found in crankshafts, connecting rods, and gears, where strength and durability are critical. Additionally, the aerospace industry employs forged steel in components like landing gears and turbine blades, where reliability is paramount.

Furthermore, the construction industry utilizes forged steel for rebar and structural components due to its ability to withstand heavy loads. In the energy sector, forged steel plays a crucial role in the production of valves, pipes, and fittings for oil, gas, and other energy applications.

Conclusion

In conclusion, varf forjat, or forged steel, represents a sophisticated technology that enhances the properties and usability of steel in numerous applications. Its strength, durability, and versatility make it a preferred choice in various industries, from automotive to aerospace and construction. As technology advances and industries evolve, the demand for forged steel is likely to grow, solidifying its position as a vital material in modern engineering and manufacturing. Understanding the intricacies of forged steel allows professionals to appreciate its capabilities and make informed decisions regarding its use in specific applications.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters