what is wrought metal

Understanding Wrought Metal An Insight into its Properties and Applications

Wrought metal is a term that refers to metals that have been mechanically worked and shaped through processes such as forging, rolling, and extrusion. This work enhances the physical properties of the metal, making it stronger, more ductile, and more suitable for various applications compared to its cast counterparts. While the term may seem esoteric, its significance is paramount in various industries, from construction to jewelry making.

The Process of Wrought Metal Production

The transformation of raw metal into wrought metal involves multiple steps. Initially, the metal is extracted from ore through processes such as smelting. After purification, the metal is shaped at elevated temperatures, which allows for easier manipulation and reduces the risk of cracking. There are two primary methods of shaping hot working and cold working.

Hot working involves deforming the metal above its recrystallization temperature, which reduces the effort required for shaping and prevents hardening. This process results in a refined grain structure, enhancing the metal's strength. Cold working, on the other hand, occurs at room temperature, leading to an increase in hardness and strength due to strain hardening. Both methods contribute to the overall material properties that define wrought metals.

Properties of Wrought Metal

One of the defining characteristics of wrought metals is their superior mechanical properties. The processes involved in their production yield a finer grain structure, which significantly improves strength and ductility. For example, wrought iron, a classic example of wrought metal, is known for its toughness and malleability. Steel, particularly wrought steel, is celebrated for its versatility, enabling its use in a wide range of applications, from construction beams to intricate machinery components.

what is wrought metal

Another notable property of wrought metals is their uniformity. Unlike cast metals, which can contain imperfections or variations in composition due to the solidification process, wrought metals typically exhibit more consistent properties. This uniformity is critical in applications where predictable performance is essential, such as in structural engineering.

Applications of Wrought Metal

The applications of wrought metal are extensive and varied. In the construction industry, wrought iron and steel are staples for creating robust infrastructures, such as bridges, buildings, and railways. Their high strength-to-weight ratio makes them ideal for structural frames that require resilience against environmental stressors.

In the automotive sector, wrought metals are employed to fabricate components that can withstand high temperatures and mechanical stress while remaining lightweight. Manufacturers use wrought aluminum for engine components and frameworks due to its favorable strength-to-weight ratio and corrosion resistance.

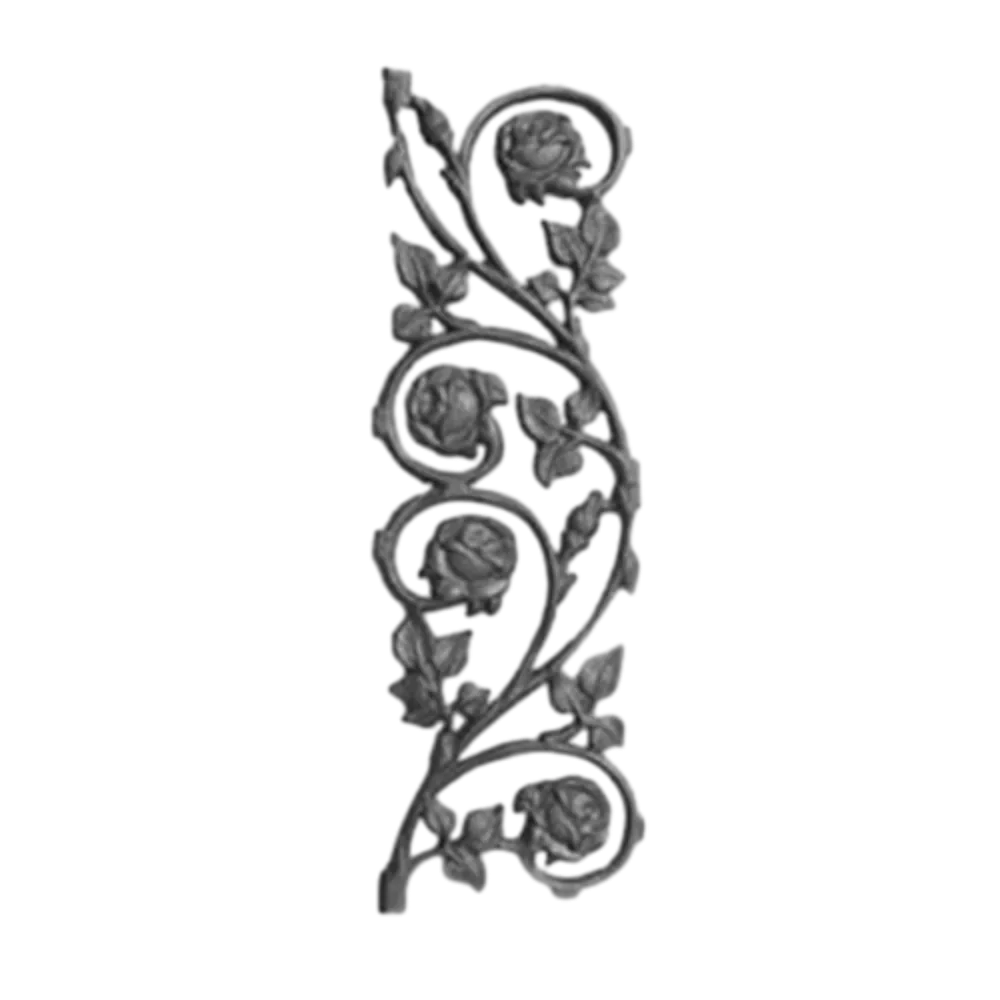

In the realm of decorative arts, wrought metals play a crucial role as well. Jewelers appreciate metals like gold and silver in their wrought forms because they can be easily shaped into intricate designs. Wrought metal is often used in artisanal creations like handmade jewelry, metalwork art, and ornamental architecture, where both aesthetic appeal and durability are desired.

Conclusion

Wrought metal is a vital material that plays an instrumental role across various industries. Its superior properties, resulting from procedural attributes and mechanical working techniques, make it a preferred choice for both functional and decorative applications. As technology advances, the techniques for creating wrought metals continue to evolve, leading to innovative applications that meet the demands of modern engineering and artistry. Understanding wrought metal not only enhances our appreciation for these materials but also highlights their importance in shaping the world around us.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters