Feb . 10, 2025 09:18

Back to list

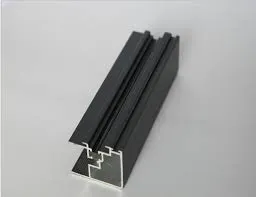

wheels in sliding doors

Sliding doors have transformed the modern architectural landscape, offering space-saving solutions and aesthetic appeal that traditional doors cannot match. However, the efficiency and longevity of sliding doors hinge significantly on the quality and condition of their wheels. In the absence of a proper wheel mechanism, even the most exquisitely designed sliding doors can become a source of daily frustration.

When considering energy efficiency, the role of sliding door wheels may not be immediately apparent, yet it is substantial. Properly functioning wheels ensure a tighter fit of doors against their frames, reducing air leaks and maintaining indoor climates effectively. This feature can contribute notably to heating and cooling efficiency, subsequently lowering energy costs. Security is another critical factor influenced by the condition of sliding door wheels. Doors that don’t close properly due to wheel malfunction can leave your property vulnerable. High-quality wheels retain the functionality of locking mechanisms and offer peace of mind by ensuring doors can be securely closed and locked. The integration of advanced technology has introduced novel improvements in sliding door wheel systems. Self-lubricating wheels or rollers with enhanced weight-bearing capacities are among the latest innovations focused on extending the lifespan and performance of sliding doors. These technological advancements are particularly beneficial in commercial applications where doors are subject to frequent and demanding use. In summary, investing in high-quality wheels for sliding doors goes beyond guaranteeing smooth sliding action. It is an investment in the durability of the door system, energy efficiency of the premises, and overall security of the property. Whether you are installing new doors or maintaining existing ones, prioritize selecting robust, suitable materials, accurate installation, and regular maintenance to ensure the continuous and effortless functioning of your sliding doors. Such an informed approach is crucial for optimizing your doors’ performance and prolonging their lifespan, embodying a smart blend of design elegance and practical functionality.

When considering energy efficiency, the role of sliding door wheels may not be immediately apparent, yet it is substantial. Properly functioning wheels ensure a tighter fit of doors against their frames, reducing air leaks and maintaining indoor climates effectively. This feature can contribute notably to heating and cooling efficiency, subsequently lowering energy costs. Security is another critical factor influenced by the condition of sliding door wheels. Doors that don’t close properly due to wheel malfunction can leave your property vulnerable. High-quality wheels retain the functionality of locking mechanisms and offer peace of mind by ensuring doors can be securely closed and locked. The integration of advanced technology has introduced novel improvements in sliding door wheel systems. Self-lubricating wheels or rollers with enhanced weight-bearing capacities are among the latest innovations focused on extending the lifespan and performance of sliding doors. These technological advancements are particularly beneficial in commercial applications where doors are subject to frequent and demanding use. In summary, investing in high-quality wheels for sliding doors goes beyond guaranteeing smooth sliding action. It is an investment in the durability of the door system, energy efficiency of the premises, and overall security of the property. Whether you are installing new doors or maintaining existing ones, prioritize selecting robust, suitable materials, accurate installation, and regular maintenance to ensure the continuous and effortless functioning of your sliding doors. Such an informed approach is crucial for optimizing your doors’ performance and prolonging their lifespan, embodying a smart blend of design elegance and practical functionality.

Prev:

Next:

Latest news

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters