wrought iron definition

Understanding Wrought Iron Definition, Characteristics, and Applications

Wrought iron is a term that often arises in discussions of metalwork, construction, and historical artifacts. Its unique properties and historical significance set it apart from other iron types, such as cast iron or steel. To better grasp the essence of wrought iron, we will explore its definition, characteristics, manufacturing process, and applications.

Definition of Wrought Iron

Wrought iron is a type of iron alloy characterized by its low carbon content, typically less than 0.08%. This distinctive composition makes it malleable and ductile, allowing it to be easily shaped and manipulated when heated. Unlike cast iron, which has a higher carbon content and is brittle, wrought iron can be worked into various forms without breaking. It is often recognized by its fibrous texture, which results from the working process that aligns the iron’s grain.

Characteristics of Wrought Iron

One of the most notable characteristics of wrought iron is its strength and resistance to corrosion. The low carbon content contributes to its flexibility and durability, making it suitable for various applications. It boasts excellent welding properties, allowing for the seamless joining of metal pieces, which is a significant advantage in construction and artistic metalwork.

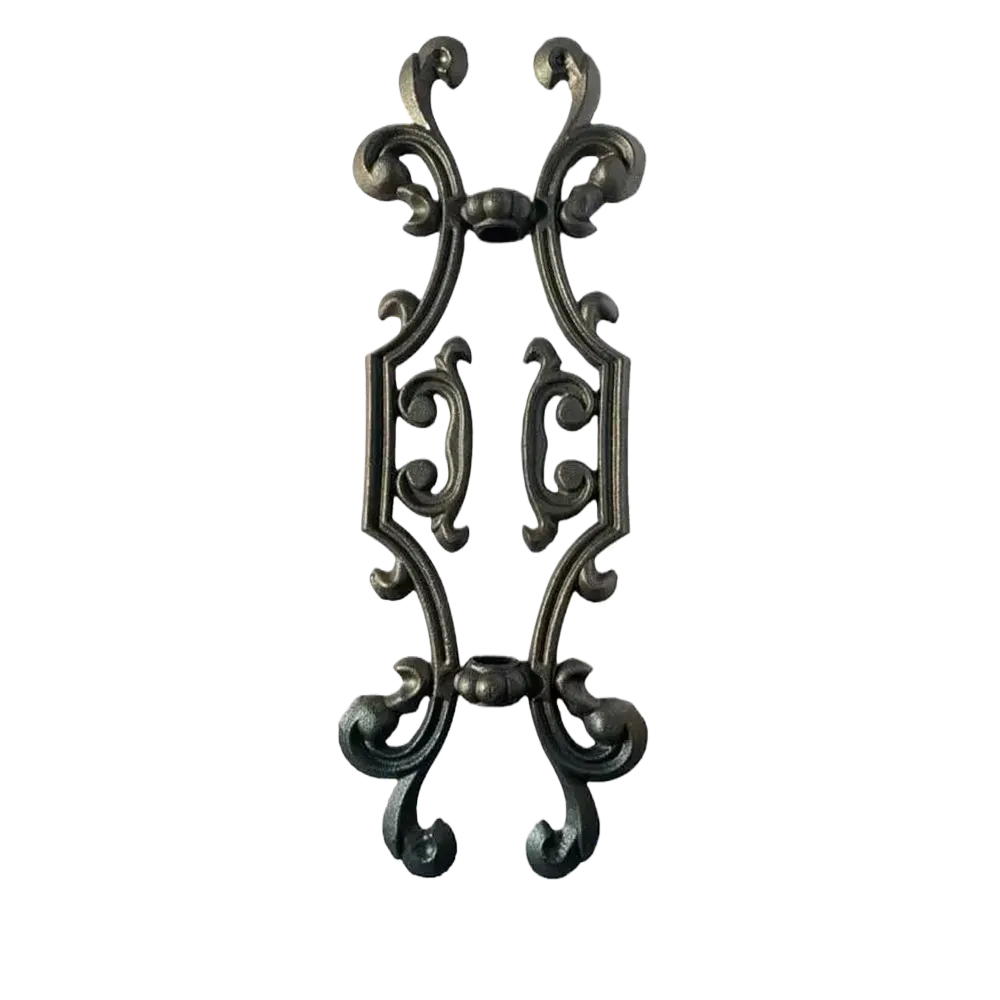

Wrought iron is also known for its aesthetic appeal. Its natural luster and ability to take on various finishes make it a preferred choice for decorative elements. The fibrous structure and surface finish can be manipulated to create intricate designs, ensuring that wrought iron remains a favored material for artists and craftsmen.

Manufacturing Process

wrought iron definition

Wrought iron is typically produced by the process of refining iron ore. The traditional method involves heating iron ore in a forge, where it is repeatedly hammered and shaped to remove impurities and excess carbon. This process results in a spongy mass known as bloom, which is then forged into bars or other shapes. Modern methods may involve using a process called puddling, where molten iron is stirred to encourage the removal of carbon and other impurities.

Despite advancements in metallurgy, the artisanal methods of producing wrought iron are still valued for their contributions to quality and craftsmanship. The combination of traditional techniques with modern technology allows for variations in composition and properties, producing wrought iron that meets specific requirements for various applications.

Applications of Wrought Iron

The versatility of wrought iron has led to its use in a wide range of applications. Historically, it was prevalent in the construction of buildings, bridges, and railings. Its strength made it ideal for structural components, while its malleability allowed for decorative elements such as scrollwork and ornamental gates.

In contemporary settings, wrought iron continues to play a significant role in architecture and design. It is commonly used for fencing, staircases, and garden furniture, providing both durability and aesthetic charm. Additionally, its timeless appeal makes it a popular choice for restoring historical buildings, ensuring that the authenticity of architecture is maintained.

Conclusion

In summary, wrought iron is a fascinating material with a rich history and unique properties. Its low carbon content, strength, flexibility, and aesthetic qualities make it an exceptional choice for various applications. Whether used in historic restorations, artistic endeavors, or modern construction, wrought iron remains a testament to the enduring nature of craftsmanship and the enduring beauty of ironwork. Understanding wrought iron not only enhances our appreciation of metalworking but also enriches our knowledge of material culture throughout history.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters