wrought iron manufacturers

The Rise of Wrought Iron Manufacturers A Testament to Craftsmanship and Innovation

Wrought iron, renowned for its malleability, strength, and aesthetic appeal, has been a favored material in construction and craftsmanship since ancient times. Today, the production of wrought iron is experiencing a renaissance, with an increasing number of manufacturers embracing traditional methods while integrating modern technologies. This article explores the significance of wrought iron manufacturers, their processes, and the growing demand for wrought iron products in contemporary society.

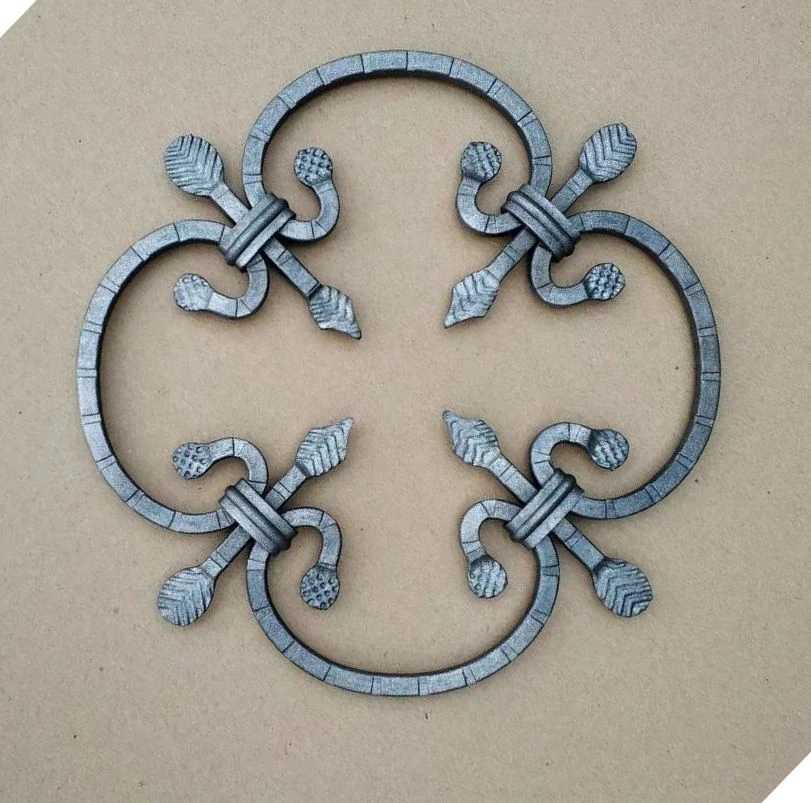

Historically, wrought iron has been used in various applications, from architectural features and ornamental designs to tools and agricultural implements. It is characterized by its fibrous structure, which makes it less brittle than cast iron and gives it superior workability. The process of producing wrought iron involves heating and hammering the iron to remove impurities and create a more ductile form. This method, often referred to as “forging,” allows artisans to create intricate designs that showcase their craftsmanship.

In recent years, the rise of wrought iron manufacturers has been driven by several factors. One of the primary reasons is the renewed interest in artisanal and handmade products. In an era dominated by mass production, consumers are increasingly seeking unique, high-quality items that reflect their personal taste and style. Wrought iron products, such as gates, railings, and furniture, fit this niche perfectly, offering not only durability but also an aesthetic charm that can enhance any space.

Moreover, the versatility of wrought iron makes it a sought-after material in both residential and commercial applications. Architects and designers appreciate its strength and adaptability, allowing them to create structures that are both functional and visually striking. From elegantly designed outdoor furniture to sturdy yet stylish stair railings, wrought iron can be tailored to suit a variety of design concepts. The ability to customize wrought iron products to meet specific client needs further solidifies its appeal in today’s market.

wrought iron manufacturers

As environmental consciousness grows, many wrought iron manufacturers are also adopting sustainable practices. Wrought iron is often recycled, reducing the need for raw materials and minimizing production waste. Many manufacturers source their iron from recycled materials, promoting a circular economy while delivering high-quality products. This commitment to sustainability resonates with consumers, who are increasingly inclined to support brands that prioritize eco-friendly practices.

Another driving force behind the contemporary resurgence of wrought iron is the integration of technology into traditional manufacturing processes. Advanced techniques such as CNC machining and laser cutting enable manufacturers to produce intricate designs with precision and efficiency. These technological advancements do not diminish the charm of wrought iron; instead, they enhance its accessibility and affordability. As a result, a broader audience can appreciate and utilize wrought iron in their projects.

In addition to traditional architectural applications, wrought iron has found its way into the art world. Many artisans and sculptors use wrought iron to create stunning pieces that serve as both functional items and works of art. This crossover between craftsmanship and artistry showcases the material’s inherent beauty and versatility, further sparking interest in wrought iron products.

Wrought iron manufacturers collaborate with architects, designers, and builders to create customized solutions that not only meet structural requirements but also enhance aesthetic value. As urban landscapes evolve, the demand for unique, durable, and visually appealing materials like wrought iron continues to grow. This trend signifies a shift towards a more personalized experience in design and construction, where the uniqueness of each project is celebrated.

In conclusion, the revival of wrought iron manufacturers reflects a broader societal trend towards craftsmanship, sustainability, and personalization. By blending traditional forging methods with modern technology, these manufacturers are breathing new life into an age-old material. As consumers increasingly seek distinctive and durable products, the future of wrought iron looks promising, with its unmatched beauty and versatility set to leave a lasting legacy in design and architecture for generations to come.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters