Feb . 14, 2025 03:25

Back to list

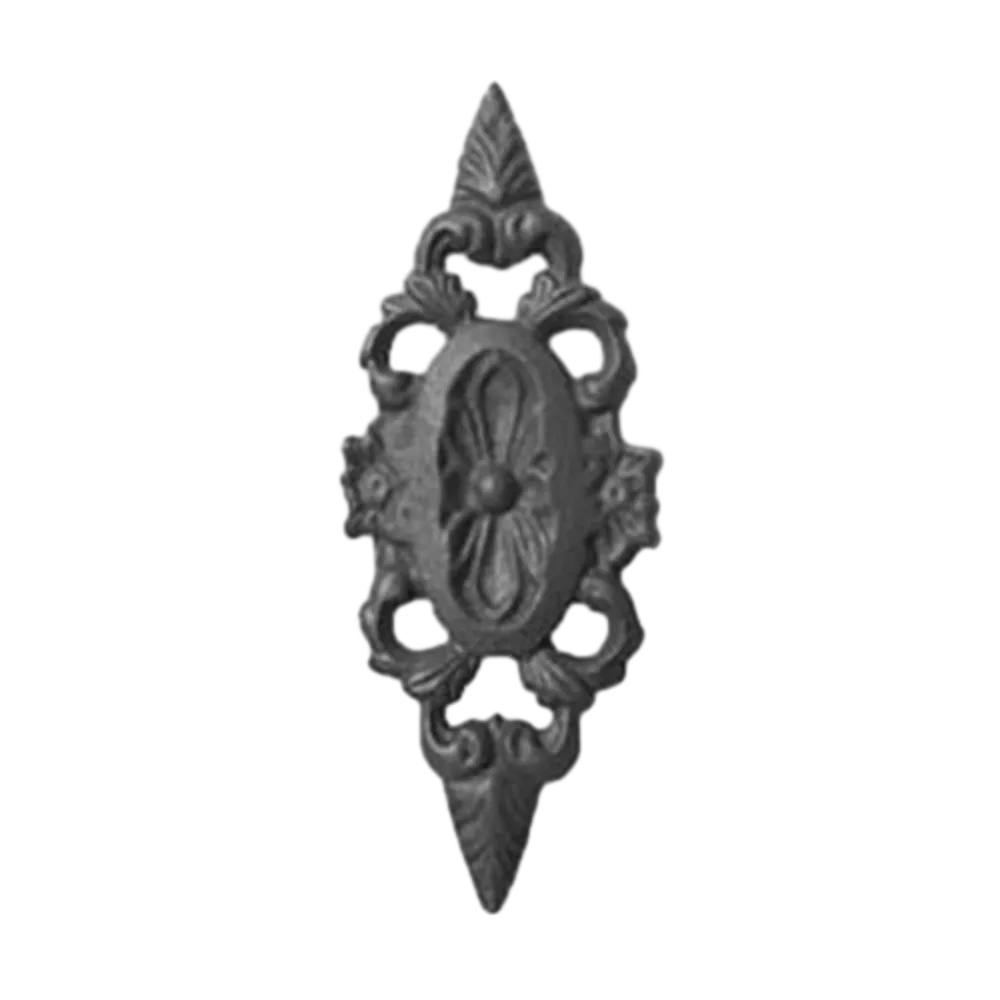

wrought iron railheads

Wrought iron parts, known for their exceptional durability and timeless aesthetic appeal, have been a staple in architectural and decorative applications for centuries. Their unique characteristics, which include easy malleability when heated and high resistance to corrosion, make them an invaluable resource in numerous sectors. As an authority in the field of wrought iron, this article aims to delve into the various applications, advantages, and considerations associated with using wrought iron parts.

For manufacturers and businesses dealing with wrought iron parts, maintaining an authoritative presence in the market relies on strict adherence to quality standards. Ensuring the purity of iron, meticulous quality control during the manufacturing process, and consistent testing for weather resistance are vital practices that uphold the part's standing as a premium product. Companies renowned for these practices earn trust and recognition within the industry and among consumers. Additionally, leveraging wrought iron parts effectively requires an understanding of market trends and consumer preferences. While traditional designs remain popular, there is a growing demand for contemporary aesthetics that incorporate wrought iron’s classic charm with modern elements. Staying ahead of these trends involves continual innovation and adapting new techniques that align with changing consumer tastes, thereby reinforcing a company's expertise and leadership in the market. Real-world experience with wrought iron parts further cements their status as a top-tier choice for construction and decoration. Many iconic structures around the world, such as the Eiffel Tower's decorative perimeter, owe their longevity and beauty to the strategic use of wrought iron. These historical examples not only illustrate the material’s capabilities but also provide a rich source of inspiration for modern applications. In conclusion, the role of wrought iron parts in the construction and decorative industries cannot be overstated. Their durability, aesthetic flexibility, and eco-friendly nature make them a universally trusted material with a deep-rooted presence in history and a future full of potential. For professionals looking to harness the full power of wrought iron in their projects, understanding its properties, maintaining high standards of production, and staying attuned to market dynamics are essential practices that ensure success and sustained authority in the field.

For manufacturers and businesses dealing with wrought iron parts, maintaining an authoritative presence in the market relies on strict adherence to quality standards. Ensuring the purity of iron, meticulous quality control during the manufacturing process, and consistent testing for weather resistance are vital practices that uphold the part's standing as a premium product. Companies renowned for these practices earn trust and recognition within the industry and among consumers. Additionally, leveraging wrought iron parts effectively requires an understanding of market trends and consumer preferences. While traditional designs remain popular, there is a growing demand for contemporary aesthetics that incorporate wrought iron’s classic charm with modern elements. Staying ahead of these trends involves continual innovation and adapting new techniques that align with changing consumer tastes, thereby reinforcing a company's expertise and leadership in the market. Real-world experience with wrought iron parts further cements their status as a top-tier choice for construction and decoration. Many iconic structures around the world, such as the Eiffel Tower's decorative perimeter, owe their longevity and beauty to the strategic use of wrought iron. These historical examples not only illustrate the material’s capabilities but also provide a rich source of inspiration for modern applications. In conclusion, the role of wrought iron parts in the construction and decorative industries cannot be overstated. Their durability, aesthetic flexibility, and eco-friendly nature make them a universally trusted material with a deep-rooted presence in history and a future full of potential. For professionals looking to harness the full power of wrought iron in their projects, understanding its properties, maintaining high standards of production, and staying attuned to market dynamics are essential practices that ensure success and sustained authority in the field.

Prev:

Next:

Latest news

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters