Reliable Wrought Iron Suppliers for Quality Metal Fabrication and Design Solutions

Understanding Wrought Iron and Its Suppliers

Wrought iron is a malleable and ductile metal formed by the refinement of iron ore. It has been utilized for centuries in various applications, including architecture, construction, and decorative arts, due to its strength, corrosion resistance, and attractive finish. Today, wrought iron continues to play an important role in modern manufacturing, thanks to its unique properties and versatility.

When seeking wrought iron suppliers, it's crucial to understand the key characteristics of wrought iron and what to look for in a trusted supplier. Wrought iron is distinct from cast iron, as it is forged and shaped through mechanical processes. This malleability allows it to be hammered and molded into intricate shapes, making it an excellent choice for ornamental work, such as gates, railings, and furniture.

The Importance of Quality

Quality is paramount when sourcing wrought iron. The ideal wrought iron should have low carbon content and should display excellent weldability and high tensile strength. A reputable supplier will provide products that meet specific industry standards, ensuring durability and reliability in various applications. When selecting a supplier, it is beneficial to inquire about their manufacturing processes and certifications to guarantee that the wrought iron products meet international quality standards.

Variety of Products

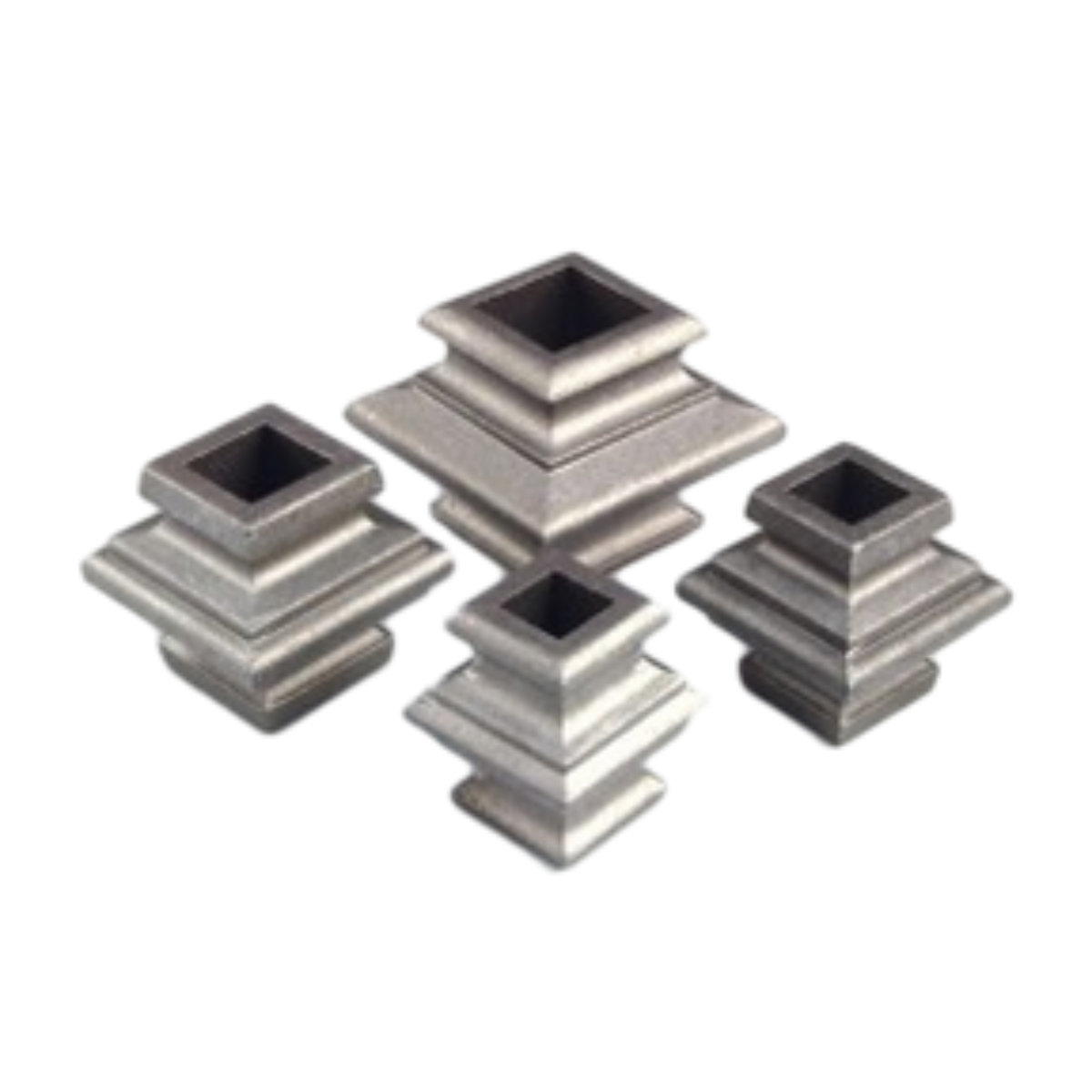

Wrought iron suppliers offer a diverse range of products, including bars, rods, sheets, and custom-designed pieces. Depending on the project requirements, clients can choose from various sizes and finishes. Some suppliers specialize in custom fabrication, allowing for tailored solutions to unique architectural designs or artistic creations. Engaging with a supplier who provides a range of products can streamline the procurement process, as clients can source multiple items from a single trusted vendor.

wrought iron suppliers

Buying Locally or Internationally

In today's globalized market, wrought iron suppliers can be found locally and internationally. Local suppliers provide the advantage of reduced shipping costs and quicker turnaround times, which is particularly beneficial for urgent projects. On the other hand, international suppliers may offer competitive pricing and a broader selection of products. When considering international suppliers, it’s essential to factor in additional considerations such as import duties, shipping logistics, and lead times.

Environmental Considerations

Sustainability is becoming increasingly important in manufacturing. Many wrought iron suppliers are adopting eco-friendly practices, such as recycling scrap metal and optimizing energy usage during production. When selecting a supplier, it may be worth exploring their commitment to sustainable practices, as this can reflect a company's overall corporate responsibility approach and impact on the environment.

Conclusion

Wrought iron continues to be a sought-after material due to its aesthetic appeal and functional characteristics. When sourcing wrought iron, potential buyers should prioritize quality, variety of products, and the supplier's sustainability practices. Whether opting for local or international suppliers, it is essential to conduct thorough research and select a partner who can meet the specific needs of the project while ensuring reliability and excellence in service. By understanding the dynamics of wrought iron suppliers, clients can make informed decisions that lead to successful project outcomes.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters