Comparing Wrought Iron and Cast Iron for Structural and Decorative Uses

Wrought Iron vs. Cast Iron Understanding the Differences

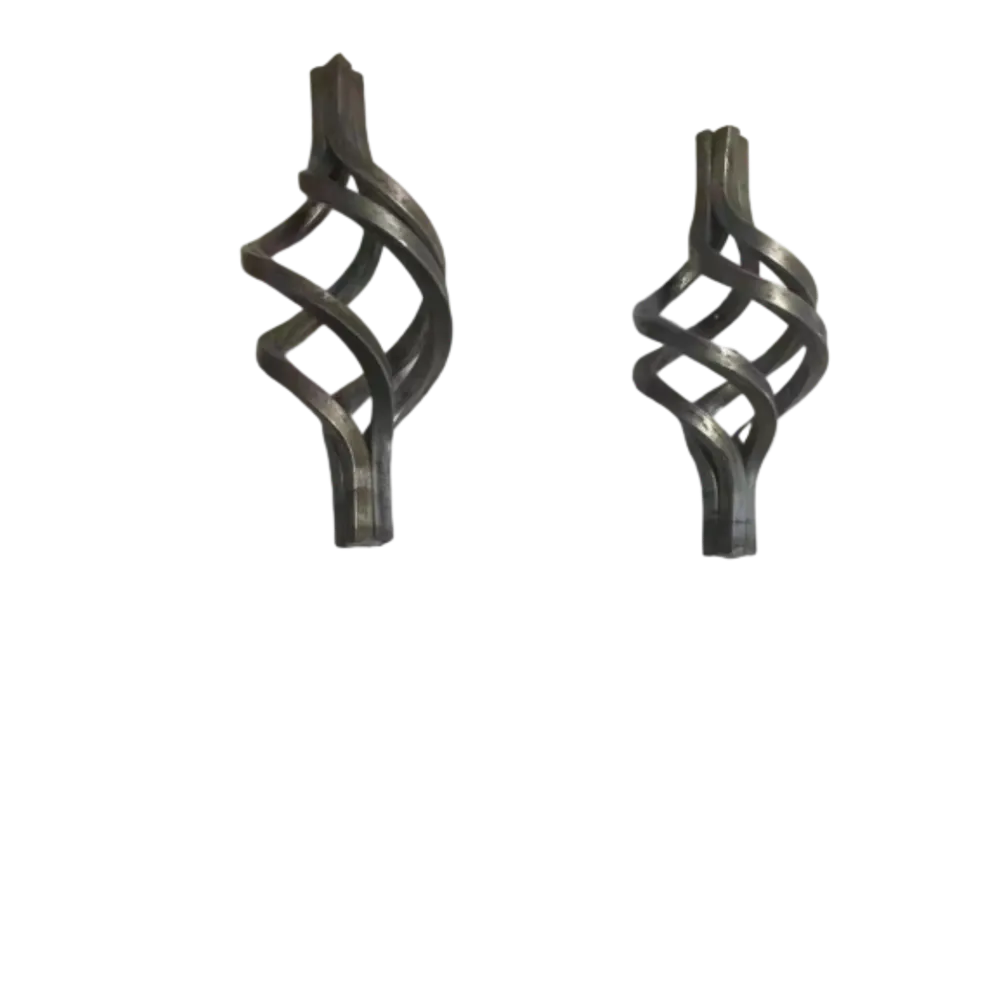

When it comes to iron products, two significant types often come to mind wrought iron and cast iron. Both materials have played crucial roles throughout history in construction, manufacturing, and decorative arts. While they may seem similar at first glance, there are distinct differences between them that can affect their usage and characteristics.

Wrought Iron vs

. Cast Iron Understanding the DifferencesOn the other hand, cast iron is produced by melting iron, along with a higher carbon content (generally between 2% to 4%), and pouring it into molds. This process allows for the creation of complex shapes and sizes that cannot be achieved with wrought iron. Cast iron is known for its excellent castability and is widely used in products like cookware, pipes, and machinery components. Its structure can vary based on the type of cast iron being produced, with gray cast iron and ductile (or nodular) cast iron being among the most common varieties.

wrought iron vs iron

One of the most significant differences between wrought iron and cast iron is their mechanical properties. Due to its low carbon content and the manner in which it is processed, wrought iron exhibits superior tensile strength and ductility compared to cast iron. This means that wrought iron can withstand greater tension and can be bent without breaking, making it ideal for applications requiring strong, resilient materials. In contrast, cast iron is more brittle, which means it can crack or break under excessive stress, making it less suitable for load-bearing structures.

In terms of corrosion resistance, wrought iron has an advantage due to its fibrous nature, which allows it to develop a protective layer of rust when exposed to moisture and air. This layer helps prevent further corrosion, making wrought iron a durable choice for outdoor applications. Cast iron, while also relatively resistant to corrosion, may require additional protective coatings or treatments, especially in harsh environments.

In summary, both wrought iron and cast iron have unique properties that make them suitable for different applications. Wrought iron is valued for its malleability, toughness, and aesthetic appeal, making it ideal for decorative structures and items requiring flexibility. In contrast, cast iron is prized for its ability to be molded into intricate shapes and its durability in heavy-duty applications. Understanding these differences can help individuals make informed decisions when selecting the right type of iron for their specific needs. Whether for artistic endeavors or industrial use, both wrought iron and cast iron continue to be valuable materials in modern manufacturing and design.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters