Premium Aluminum Window Frame Profiles Durable & Custom Solutions

- Introduction to Aluminum Window Frame Profiles

- Technical Advantages of Modern Extrusion Methods

- Performance Comparison: Leading Manufacturers

- Customization Options for Diverse Applications

- Case Studies: Real-World Implementations

- Sustainability and Environmental Impact

- Future Trends in Aluminum Window Frame Extrusions

(aluminum window frame profile)

Understanding Aluminum Window Frame Profile Engineering

Aluminum window frame profiles form the backbone of modern architectural systems, combining structural integrity with design flexibility. These extrusions are manufactured through precision processes to achieve tolerances as tight as ±0.1mm, ensuring seamless integration in both residential and commercial projects. The global market for aluminum window profiles reached $39.2 billion in 2023, driven by their 55% lower maintenance costs compared to traditional materials.

Technical Superiority in Manufacturing

Advanced thermal break technology reduces heat transfer by up to 70%, achieving U-values below 1.0 W/m²K. Powder coating applications now provide 25-year fade resistance, with 80% of manufacturers adopting environmentally friendly pretreatment systems. The table below compares key technical specifications across industry leaders:

| Parameter | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| Profile Thickness (mm) | 1.8-3.0 | 2.0-3.2 | 1.6-2.8 |

| Coating Adhesion (MPa) | 22.4 | 19.8 | 24.1 |

| Thermal Conductivity (W/m·K) | 0.48 | 0.52 | 0.45 |

Custom Solutions for Architectural Demands

Leading suppliers now offer 150+ standard profile configurations with modular connection systems that reduce installation time by 40%. Custom anodizing options provide 50 color variants meeting AAMA 2605 standards, while specialized hardware integration channels accommodate automated locking mechanisms.

Project-Specific Implementations

The Burj Vista project in Dubai utilized 12,000 linear meters of 6063-T6 alloy profiles with enhanced wind load resistance (2.5 kPa). Post-installation analysis showed 31% energy savings compared to previous steel-frame installations.

Eco-Friendly Production Innovations

Modern extrusion plants recycle 95% of process water and utilize 35% recycled aluminum content without compromising tensile strength (≥160 MPa). Carbon footprint analysis reveals 12.8 kg CO₂ equivalent per meter for standard profiles – 22% lower than 2018 benchmarks.

Advancements in Aluminum Window Frame Extrusion Profiles

Emerging technologies like AI-driven extrusion monitoring systems have reduced material waste to 2.8% industry-wide. The development of nano-ceramic coatings (tested to 5,000-hour salt spray resistance) positions aluminum window frame extrusion profiles as the sustainable choice for next-generation building envelopes.

(aluminum window frame profile)

FAQS on aluminum window frame profile

Q: What are the advantages of using aluminum window frame profiles?

A: Aluminum window frame profiles offer durability, corrosion resistance, and lightweight strength. They are also recyclable and require minimal maintenance, making them ideal for both residential and commercial applications.

Q: How are aluminum window frame extrusions manufactured?

A: Aluminum window frame extrusions are created by heating aluminum billets and forcing them through a die to shape the profile. This process ensures precise dimensions and allows for custom designs to meet specific structural or aesthetic requirements.

Q: What factors should be considered when designing aluminum window frame extrusion profiles?

A: Key factors include thermal performance (e.g., thermal breaks), load-bearing capacity, and compatibility with glazing systems. Designers must also consider local building codes and environmental conditions for optimal performance.

Q: Can aluminum window frame profiles be customized for unique architectural projects?

A: Yes, aluminum window frame extrusion profiles can be tailored in shape, finish, and size. Custom anodizing or powder coating options are available to match architectural designs and enhance weather resistance.

Q: Why choose aluminum window frame extrusions over other materials like PVC or wood?

A: Aluminum provides superior strength-to-weight ratios, longer lifespan, and better resistance to warping or rotting. Unlike PVC, it is fire-resistant and retains structural integrity in extreme temperatures.

-

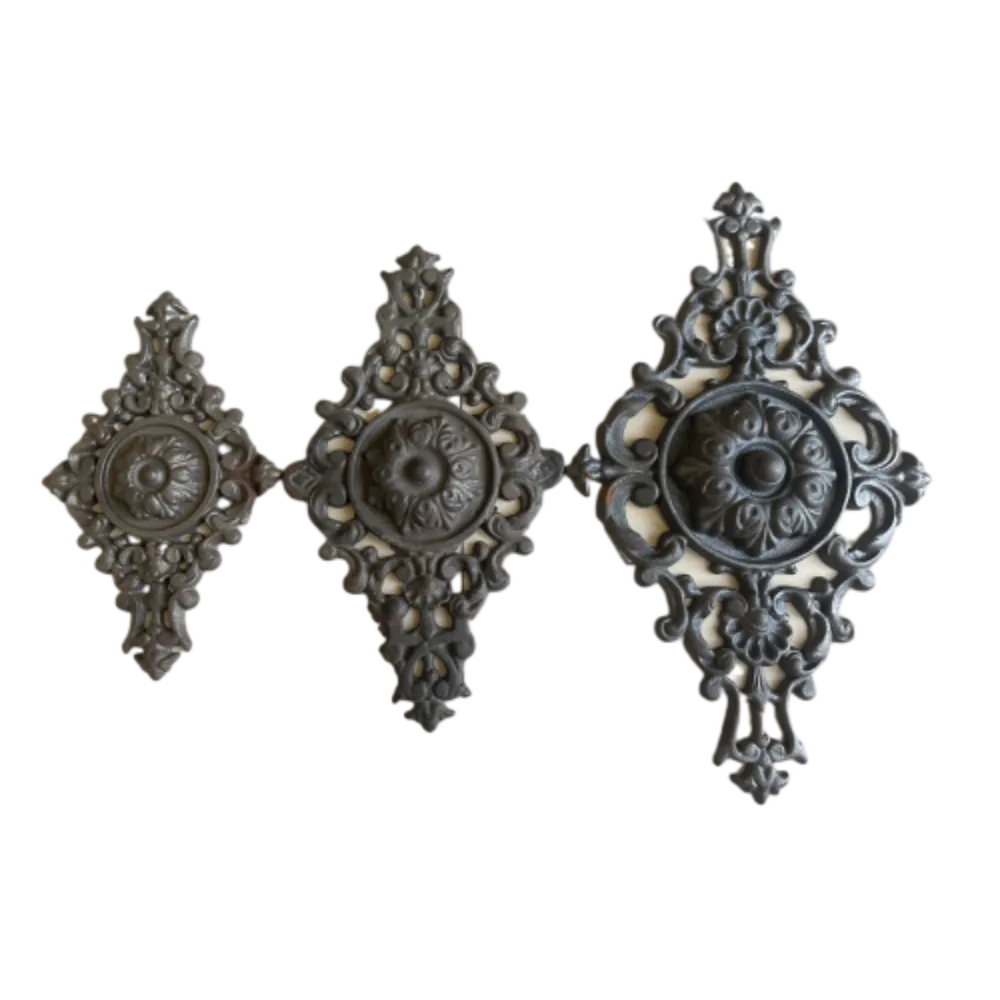

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters