rusting wrought iron

Rusting Wrought Iron Causes, Effects, and Prevention

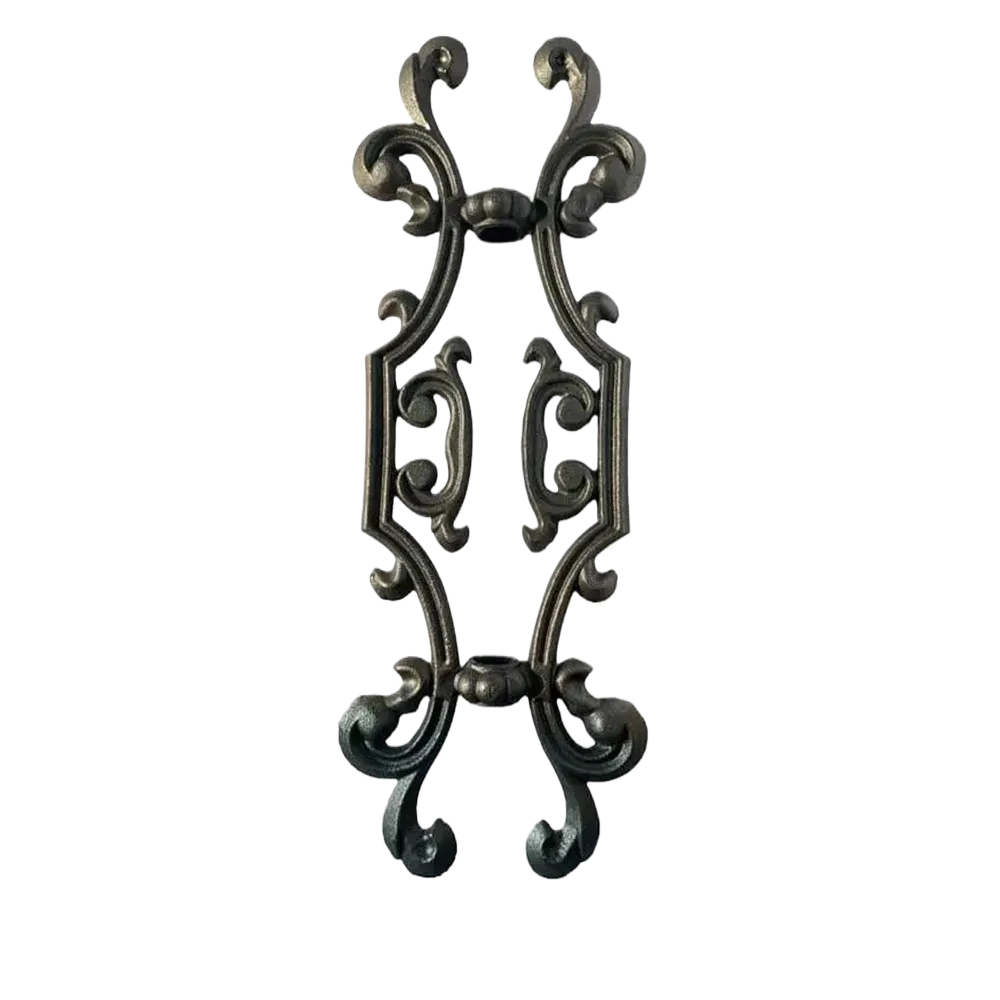

Wrought iron, known for its malleability and tensile strength, has long been utilized in various construction and decorative applications. However, its susceptibility to rusting remains a significant concern for both artisans and engineers. Rusting, or the corrosion of iron, is a chemical process that occurs when iron reacts with oxygen in the presence of moisture. Understanding the causes and effects of rusting wrought iron, as well as methods of prevention, is essential for preserving its integrity and appearance.

The primary factor contributing to the rusting of wrought iron is moisture. This can stem from direct exposure to rain, humidity in the air, or even condensation. When these elements come into contact with the iron, they initiate a series of electrochemical reactions that lead to oxidation. This process transforms the iron into iron oxide, commonly known as rust, which manifests as a reddish-brown flaky substance. Besides moisture, other environmental factors such as salt from seawater or de-icing agents used on roads can accelerate rusting. These substances can increase the corrosive effect on wrought iron, posing a greater threat in coastal areas or during winter months.

rusting wrought iron

The effects of rusting wrought iron can be both aesthetic and structural. Visually, rust can significantly diminish the beauty of wrought iron, which is often used for decorative purposes like gates, railings, and furniture. The flaky, discolored appearance of rusted iron is unattractive and can detract from the craftsmanship of the piece. Structurally, rust can weaken wrought iron over time, leading to potential failure of load-bearing structures. Corrosion can create vulnerabilities, leading to cracks and eventual breakage, which can pose safety risks, particularly in architectural applications.

Preventing rust on wrought iron requires a proactive approach. First and foremost, applying protective coatings is crucial. Paint, galvanization, and specialized corrosion-resistant coatings can create a barrier between the iron and environmental factors. These coatings should be maintained regularly, as they can wear down over time. Additionally, keeping wrought iron structures clean and free of moisture can help reduce rust formation. Regular inspections can also aid in early detection of rust, allowing for timely intervention before extensive damage occurs.

In conclusion, while wrought iron is renowned for its strength and versatility, it remains vulnerable to rust. Understanding the causes of corrosion and its detrimental effects is essential for ensuring the longevity of wrought iron structures and artworks. Through proper care, protective measures, and regular maintenance, it is possible to preserve the beauty and integrity of wrought iron, making it a lasting choice for various applications. Emphasizing prevention will not only enhance the lifespan of these creations but also uphold their aesthetic value within our environments.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters