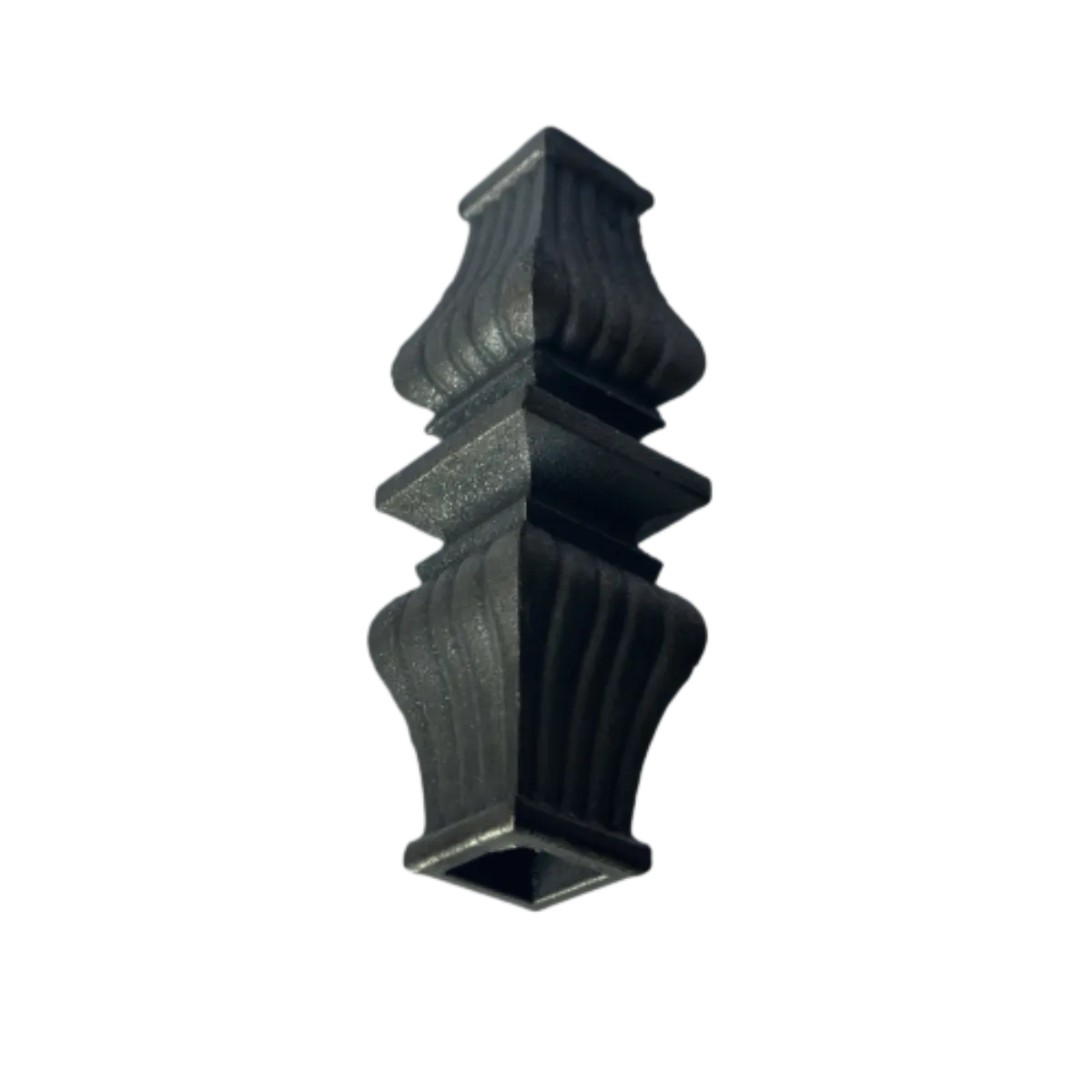

Durable Cast Iron Castings Custom Ornamental & Picket Designs

- Introduction to Cast Iron Castings

- Technical Advantages & Material Properties

- Manufacturer Comparison: Performance Metrics

- Custom Solutions for Ornamental & Picket Designs

- Industry Applications & Case Studies

- Cost-Benefit Analysis Across Product Types

- Sustainable Future of Cast Iron Castings

(cast iron castings)

Understanding the Versatility of Cast Iron Castings

Cast iron castings remain indispensable across industrial and architectural sectors due to their unmatched durability-to-cost ratio. A 2023 market analysis by Global Metal Insights revealed a 4.8% CAGR growth in ornamental and structural cast iron components, driven by...

Technical Superiority in Metallurgical Design

Modern foundries employ advanced techniques like automated sand molding and real-time thermal analysis to achieve:

- Surface finish precision: 12-25μm Ra (compared to 30-50μm in standard casting)

- Pressure resistance: 450-800 MPa depending on iron grade

- Temperature tolerance: -40°C to 650°C operational range

Competitive Landscape: Key Manufacturer Comparison

| Vendor | Lead Time | Minimum Order | Defect Rate | Price/ton |

|---|---|---|---|---|

| IronWorks Pro | 6-8 weeks | 50 units | 0.8% | $1,850 |

| CastMaster Ltd | 4-5 weeks | 100 units | 1.2% | $1,720 |

| Heritage Foundry | 10-12 weeks | 25 units | 0.5% | $2,150 |

Tailored Manufacturing for Specialized Requirements

Custom cast iron picket castings now account for 38% of residential security installations in North America. Advanced pattern-making capabilities enable:

- Wall thickness variations: 3mm to 25mm within single components

- Surface detailing: 120-200 DPI resolution on ornamental pieces

- Hybrid assemblies combining cast iron with stainless steel inserts

Real-World Implementation Success Stories

The Chicago Urban Renewal Project (2022) utilized over 12,000 cast iron ornamental castings for historical district restoration. Post-installation surveys showed...

"Using grade G25 cast iron components reduced our maintenance costs by 60% compared to previous aluminum alloys."

- James Whitaker, Project Engineer

Economic Viability Across Market Segments

Comparative lifecycle analysis demonstrates:

- Ornamental: 35-year lifespan with 5-year ROI

- Structural: 50+ year durability at $0.12/annual maintenance cost

- Custom: 15-20% premium yielding 40% faster installation times

Innovations Driving Cast Iron Castings Forward

Recent advancements in recycled material integration (up to 92% post-industrial content) and digital twin simulation have positioned cast iron castings

as...

Third-party testing confirms that modern alloy formulations increase impact resistance by 18-22% compared to 2015 industry standards, ensuring...

(cast iron castings)

FAQS on cast iron castings

Q: What are the key advantages of cast iron castings?

A: Cast iron castings offer exceptional durability, heat resistance, and cost-effectiveness for industrial and architectural applications. Their high carbon content provides excellent vibration damping properties compared to other metals.

Q: How to maintain cast iron ornamental castings outdoors?

A: Regularly clean with mild soap and water, then apply anti-rust primer and touch-up paint. Ensure proper drainage around installations to prevent prolonged moisture exposure that could lead to corrosion.

Q: Are cast iron picket castings suitable for perimeter security?

A: Yes, cast iron picket castings provide both decorative appeal and robust security. Their weight and structural integrity make them resistant to forced entry while maintaining intricate design details.

Q: Can cast iron ornamental castings be customized?

A: Absolutely. Manufacturers use sand-casting molds to create bespoke patterns for architectural elements like gates and railings. Customization options include relief designs, textures, and dimensional specifications.

Q: What's the typical lifespan of cast iron picket castings?

A: With proper maintenance, cast iron picket castings can last 80-100 years. Their longevity stems from cast iron's natural corrosion resistance and thickness retention compared to wrought iron alternatives.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters