Thermal Insulated Aluminum Profiles for Enhanced Energy Efficiency and Performance

Understanding Thermal Break Aluminum Profiles A Key to Energy Efficiency and Performance

In the realm of modern construction and architecture, thermal break aluminum profiles have emerged as a pivotal component in enhancing the energy efficiency and performance of buildings. With a growing emphasis on sustainability and energy conservation, these innovative profiles offer a solution that effectively bridges the gap between design and functionality. This article delves into the concept, benefits, and applications of thermal break aluminum profiles.

What are Thermal Break Aluminum Profiles?

Thermal break aluminum profiles are specially designed extrusions that include a non-conductive material inserted between the inner and outer sections of the aluminum framework. This non-conductive barrier is typically composed of polyamide or other insulating materials. The purpose of this thermal break is to minimize the transfer of heat and cold, making these profiles ideal for windows, doors, and curtain walls.

By disrupting the direct path of thermal conductivity, these profiles help maintain a stable indoor temperature, reducing the demand for heating and cooling systems. This not only enhances comfort but also contributes significantly to energy savings.

Benefits of Thermal Break Aluminum Profiles

1. Improved Energy Efficiency One of the primary benefits of thermal break aluminum profiles is their ability to improve a building's energy efficiency. By reducing thermal bridging—where heat escapes or enters through conductive materials—these profiles help maintain the desired interior climate, ultimately lowering energy bills.

2. Enhanced Comfort With improved thermal insulation, spaces within buildings stay more comfortable throughout the year. This prevents cold drafts in the winter and reduces the soaring temperatures often experienced during summer. Consequently, the need for heating and cooling is significantly minimized.

3. Condensation Control Thermal break profiles also help in controlling condensation. By reducing the surface temperature of the interior side of the aluminum frames, the likelihood of moisture buildup and its associated issues—such as mold and damage—are substantially reduced.

4. Aesthetic Flexibility In addition to their functionality, thermal break aluminum profiles allow for a variety of design choices. They can be crafted to fit diverse architectural styles, modern or traditional, while still providing superior energy performance.

thermal break aluminum profile

5. Durability and Low Maintenance Aluminum is known for its robustness and longevity. When combined with thermal break technology, these profiles are resistant to wear and tear caused by weather, ensuring that they maintain their performance and appearance over time with minimal maintenance.

6. Sustainability Many manufacturers of thermal break aluminum profiles adhere to sustainable practices, using recycled materials and environmentally friendly production techniques. Choosing these profiles can contribute to LEED (Leadership in Energy and Environmental Design) certification for buildings, further underscoring their relevance in eco-friendly construction practices.

Applications of Thermal Break Aluminum Profiles

The versatility of thermal break aluminum profiles makes them suitable for a wide range of applications across various sectors.

1. Residential Buildings Homeowners seeking energy-efficient solutions for windows and doors often opt for thermal break profiles to ensure energy savings and comfort.

2. Commercial Properties In commercial architecture, where large glass facades and curtain walls are common, thermal break aluminum profiles are crucial for maintaining temperature control and reducing operational costs.

3. Industrial Facilities These profiles also find applications in industrial buildings where insulation is vital for material storage and operational efficiency.

4. High-rise Developments In tall structures, where thermal stratification can lead to increased energy demands, thermal break aluminum profiles are essential for balancing temperature across different building levels.

Conclusion

In conclusion, thermal break aluminum profiles are an essential innovation in the building materials industry, offering a blend of energy efficiency, comfort, and aesthetic appeal. As the construction sector continues to embrace sustainable practices, the demand for such advanced materials will likely grow. Adopting thermal break technology not only optimizes the thermal performance of buildings but also reinforces the commitment to energy conservation and environmental stewardship. As architects and builders look toward the future, thermal break aluminum profiles will play a critical role in shaping energy-efficient and sustainable spaces.

-

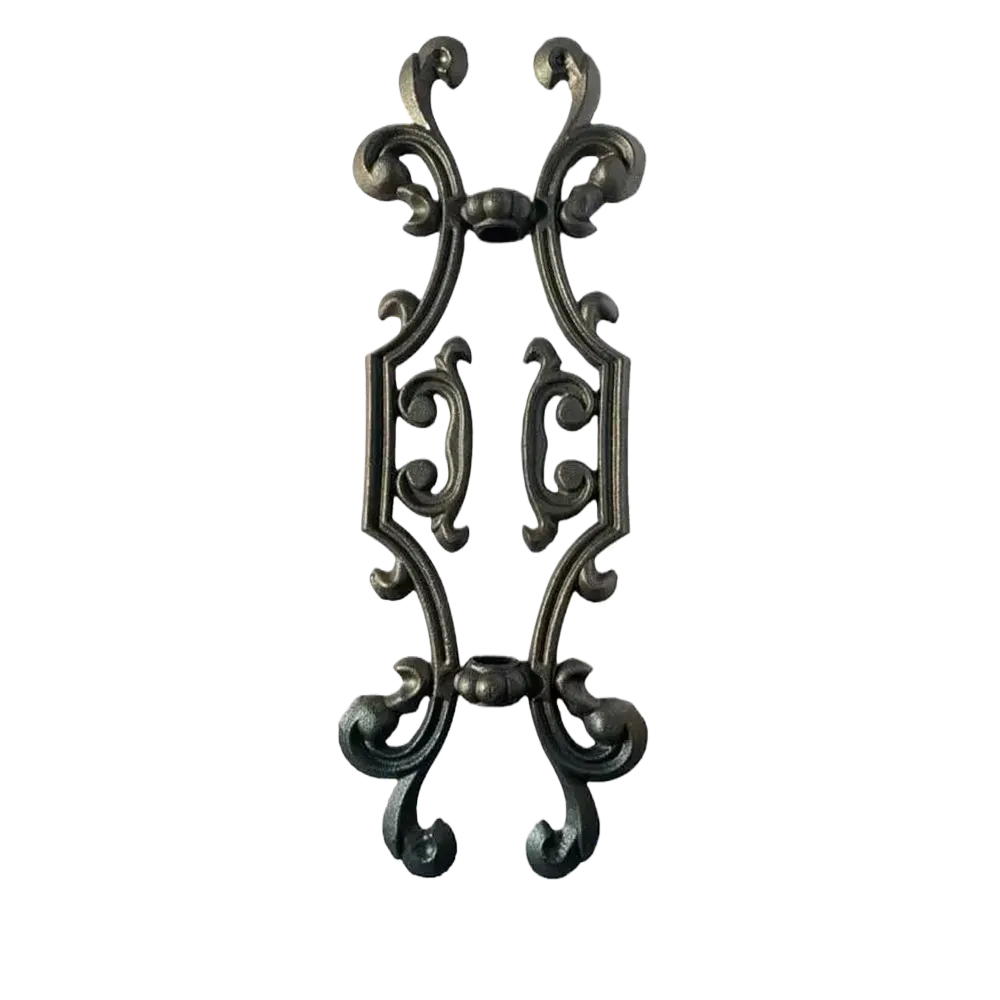

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters