Feb . 14, 2025 18:16

Back to list

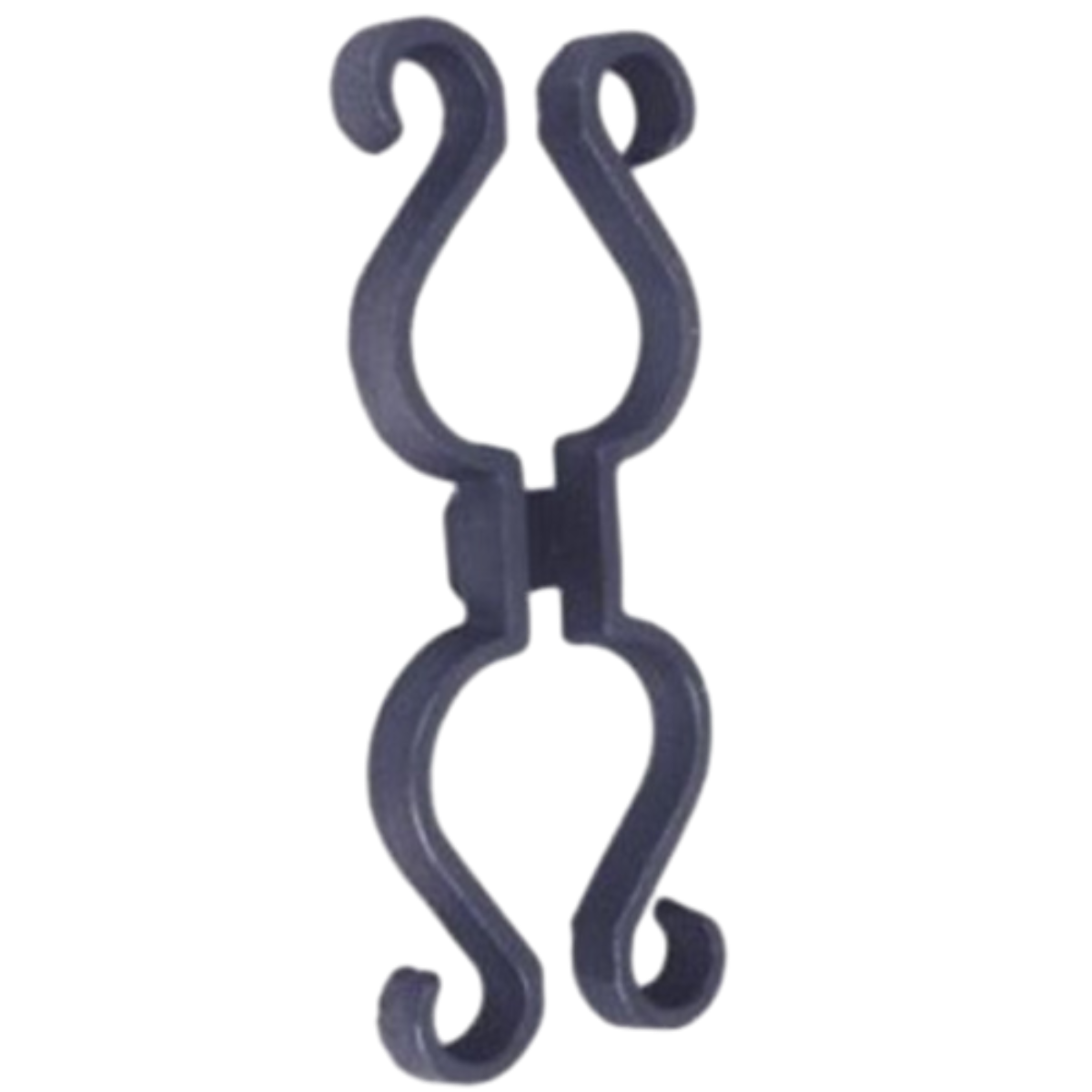

Decorative Finals

Wrought metal represents a fascinating journey from raw material to a variety of highly functional and decorative products. At the heart of this transformation are techniques honed over centuries, coupled with modern technological advancements, that illuminate the pragmatic and aesthetic possibilities of wrought metals.

Authoritativeness in the field of wrought metal emerges from a rich history of usage and continual innovation. Throughout history, wrought metal has never wavered in its usage due to its dependability, resistance to stress, and versatility. Publications and academic research journals steadily contribute to an authoritative understanding of metal properties, assessing how factors like temperature, pressure, and chemical treatments affect wrought metals. Institutions offering specialized courses in metallurgy train future professionals who carry forward the authoritative knowledge accumulated over generations, ensuring the secrets of wrought metalworking remain robustly documented and applied. Trustworthiness regarding wrought metal's reputation is built on centuries of proven efficacy in both aesthetic and structural aspects. Trust is further augmented by third-party certifications and endorsements that ensure that metallurgy products adhere to stringent quality standards. Industry bodies often play a pivotal role in establishing benchmarks for performance and safety, which in turn reassures consumers and businesses opting for wrought metal products. For anyone considering wrought metals, understanding their legacy, properties, and applications is paramount. The fusion of enduring craftsmanship and contemporary techniques ensures that this class of metal will continue to stand the test of time. From a simple hand-forged ring to expansive structural frameworks, wrought metal remains indispensable owing to its combination of beauty, durability, and trustworthiness. As innovation continues and emerging technologies are applied to metalworking, wrought metal's future remains as bright and promising as its illustrious past.

Authoritativeness in the field of wrought metal emerges from a rich history of usage and continual innovation. Throughout history, wrought metal has never wavered in its usage due to its dependability, resistance to stress, and versatility. Publications and academic research journals steadily contribute to an authoritative understanding of metal properties, assessing how factors like temperature, pressure, and chemical treatments affect wrought metals. Institutions offering specialized courses in metallurgy train future professionals who carry forward the authoritative knowledge accumulated over generations, ensuring the secrets of wrought metalworking remain robustly documented and applied. Trustworthiness regarding wrought metal's reputation is built on centuries of proven efficacy in both aesthetic and structural aspects. Trust is further augmented by third-party certifications and endorsements that ensure that metallurgy products adhere to stringent quality standards. Industry bodies often play a pivotal role in establishing benchmarks for performance and safety, which in turn reassures consumers and businesses opting for wrought metal products. For anyone considering wrought metals, understanding their legacy, properties, and applications is paramount. The fusion of enduring craftsmanship and contemporary techniques ensures that this class of metal will continue to stand the test of time. From a simple hand-forged ring to expansive structural frameworks, wrought metal remains indispensable owing to its combination of beauty, durability, and trustworthiness. As innovation continues and emerging technologies are applied to metalworking, wrought metal's future remains as bright and promising as its illustrious past.

Next:

Latest news

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters