Exploring the Benefits and Techniques of Iron Casting in Modern Manufacturing

The Art and Science of Iron Casting

Iron casting is one of the oldest manufacturing processes known to humanity, with a history that dates back thousands of years. This unique technique involves pouring liquid iron into a mold to create a solid object, and it has played a crucial role in the development of various industries, from automotive to construction. As we explore the intricacies of iron casting, we uncover its significance, processes, and the future it holds.

Historical Context

The origins of iron casting can be traced back to ancient civilizations. The Chinese, for instance, were casting iron as early as the 5th century BCE. This process not only revolutionized tools and weaponry but also laid the groundwork for more advanced metallurgy. The invention of the blast furnace in the Middle Ages increased the efficiency of iron production, making it more accessible and facilitating the rise of the Industrial Revolution.

The Casting Process

Iron casting involves several key steps that determine the quality of the final product.

1. Pattern Making The first step in the casting process is creating a pattern, which is a replica of the final object. Patterns can be made from various materials, including wood, metal, or plastic. The choice of material depends on the complexity of the design and the number of casts needed.

2. Mold Creation Once the pattern is ready, a mold is formed around it. The mold can be made from sand, metal, or ceramic, with sand casting being the most common method due to its cost-effectiveness and versatility. The sand is mixed with a binding agent, typically clay, and then compacted around the pattern to create a negative impression.

3. Melting and Pouring The next step involves melting the iron, which is usually done in a furnace. The melted iron is then poured into the mold through a gating system. This process requires precision, as the temperature and speed of pouring can affect the integrity of the cast.

4. Cooling and Finishing After the molten iron has been poured into the mold, it is left to cool and solidify. Once cooled, the mold is removed, and the cast is cleaned and finished. This may involve machining, grinding, or painting to achieve the desired surface finish and dimensions.

iron casting

Applications of Iron Casting

Iron casting is prevalent in various industries due to its durability, strength, and versatility. Common applications include engine blocks in automobiles, piping, architectural elements, and machinery parts. The ability to cast complex shapes makes iron casting invaluable in sectors where precision and reliability are paramount.

Additionally, iron castings are crucial in creating various infrastructure components, including manhole covers and park benches. The aesthetic appeal of cast iron has also contributed to its use in decorative items, combining functionality with artistry.

Environmental Considerations

As with many industrial processes, iron casting has environmental implications. Traditional methods often involve high energy consumption and emissions. However, the industry has seen significant advancements in recent years, with a focus on sustainable practices. Innovations such as using recycled materials in the casting process and adopting energy-efficient technologies are helping to reduce the carbon footprint associated with iron casting.

The Future of Iron Casting

Looking ahead, the future of iron casting appears promising. The integration of technology, such as computer-aided design (CAD) and additive manufacturing, is enabling more complex designs and reducing waste. The growth of the electric vehicle market, which requires advanced components, will likely drive demand for innovative iron casting techniques.

Moreover, as industries strive for sustainability, the continued development of eco-friendly casting materials and methods will play a vital role in ensuring that iron casting remains a relevant and responsible choice in manufacturing.

Conclusion

Iron casting is a testament to human ingenuity, blending ancient techniques with modern technology. Its applications are diverse, its history rich, and its future bright. As we continue to innovate and prioritize sustainability, the art and science of iron casting will undoubtedly remain a cornerstone of manufacturing for generations to come.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

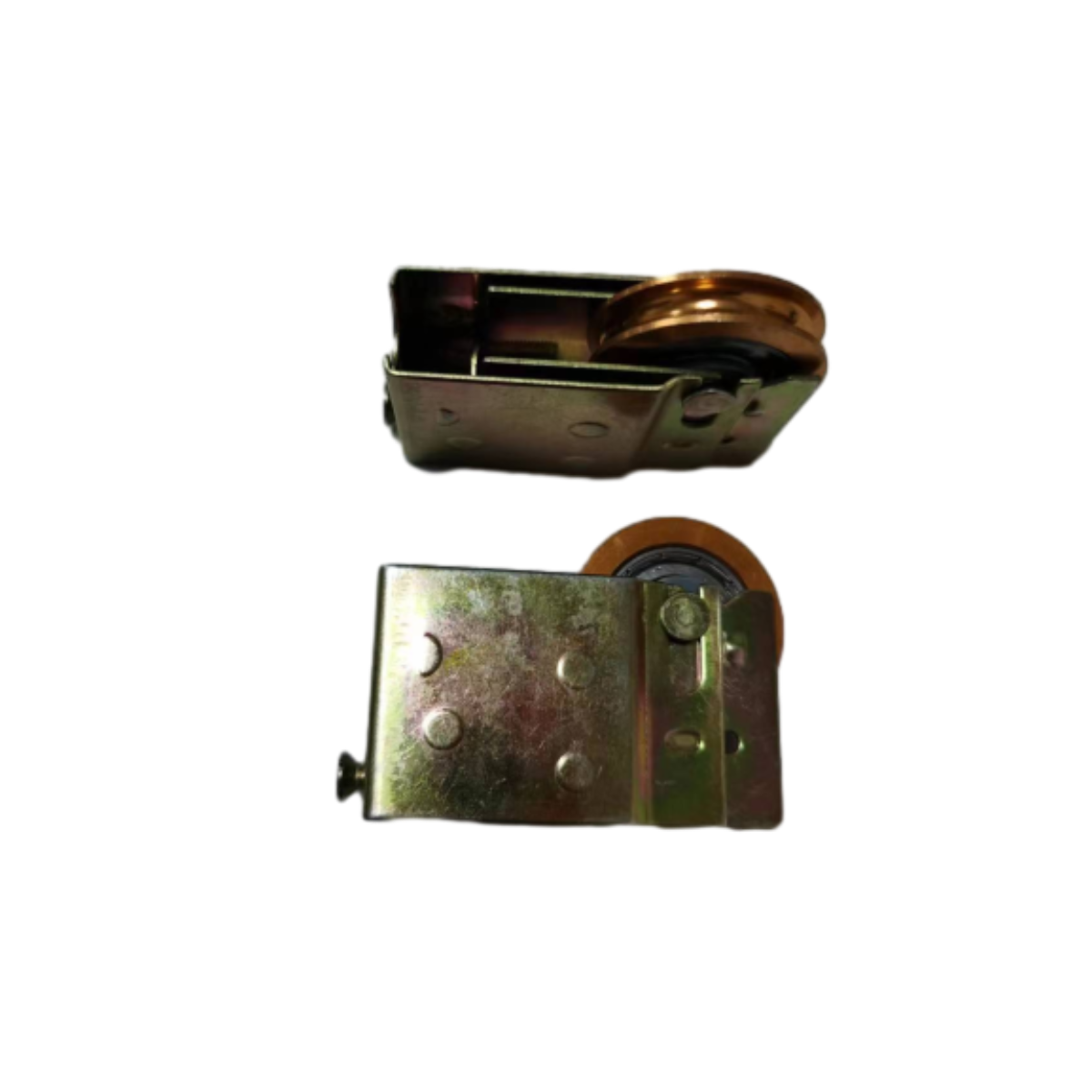

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters