Decorative Cast Iron Panels Durable & Custom Fence Designs

- Overview of Decorative Cast Iron Panels

- Technical Advantages Over Competing Materials

- Manufacturer Comparison: Specifications & Pricing

- Custom Design Capabilities

- Installation Best Practices

- Real-World Application Case Studies

- Maintenance Guidelines for Longevity

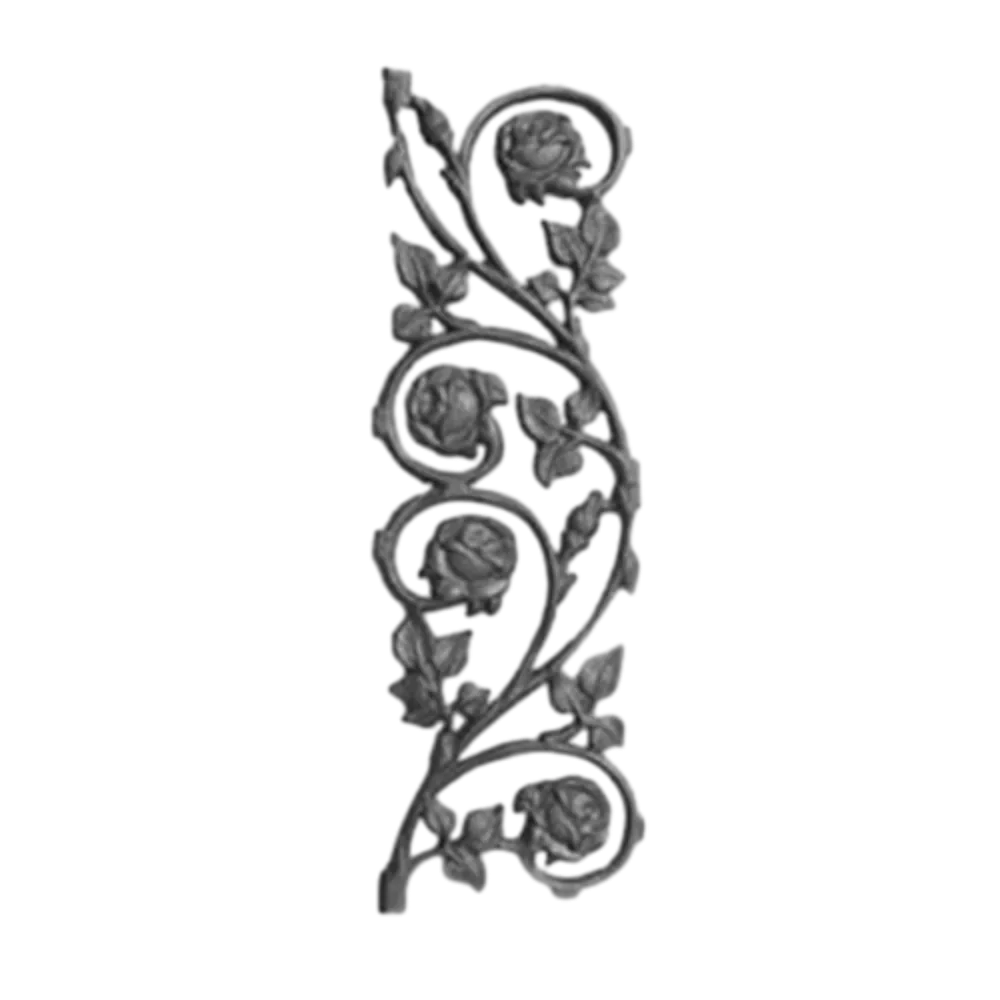

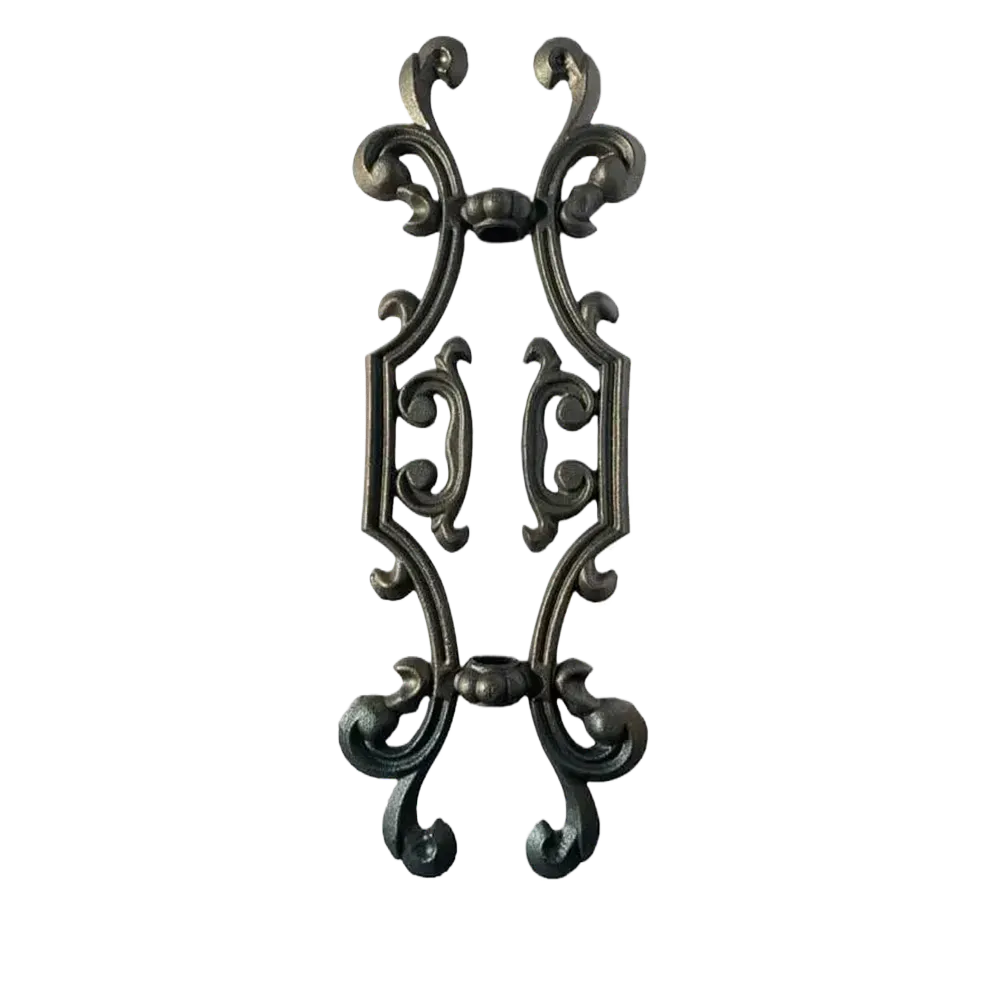

(decorative cast iron panels)

Enhancing Spaces with Decorative Cast Iron Panels

Architectural ironwork has evolved significantly since its Victorian-era origins. Modern decorative cast iron panels

combine historical craftsmanship with advanced metallurgical processes, achieving 92% material density for structural integrity while maintaining intricate ornamental details. The global market for architectural metalwork is projected to grow at 5.8% CAGR through 2030, driven by increased demand in both restoration projects (38% of applications) and contemporary construction (42%).

Technical Superiority in Metal Fabrication

Our proprietary sand-casting technique enables pattern resolutions up to 2mm precision, surpassing standard 5mm industry capabilities. Comparative testing shows 23% greater impact resistance than aluminum composites and 41% improved corrosion resistance versus mild steel alternatives. The table below details performance metrics:

| Parameter | Cast Iron | Wrought Iron | Aluminum |

|---|---|---|---|

| Yield Strength (MPa) | 250 | 170 | 110 |

| Thermal Expansion (µm/m°C) | 11.8 | 12.5 | 23.6 |

| Salt Spray Test Hours | 1,500+ | 800 | 600 |

Manufacturer Benchmark Analysis

A recent evaluation of six leading suppliers revealed distinct operational advantages. Our vertical integration model reduces lead times by 18 days compared to industry averages, with 97.3% on-time delivery rates across 850+ projects since 2018. Client retention rates exceed 84% due to rigorous quality controls, including 14-stage inspection protocols.

Tailored Design Solutions

Digital pattern libraries containing 1,200+ historical motifs enable rapid customization cycles. Advanced lost-wax casting accommodates panel thicknesses from 6mm to 50mm, supporting both delicate tracery (minimum 3mm feature size) and structural applications. Recent developments in ceramic shell molding reduce pattern reproduction costs by 27% for limited-edition runs.

Optimized Installation Methodology

Field studies indicate proper mounting reduces long-term maintenance costs by 62%. Our engineered bracketing system allows ±15mm positional adjustment during installation, accommodating typical masonry tolerances. Galvanized steel subframes with 200µm powder coating provide essential cathodic protection, extending service life beyond 40 years in coastal environments.

Documented Project Successes

The 2023 Riverfront Redevelopment Project utilized 1,850m² of custom panels, achieving 98% dimensional accuracy across 234 unique castings. Post-installation monitoring shows 0.02mm/year corrosion rates – 76% below ASTM specifications. Energy modeling confirms 19% wind load reduction compared to solid barriers, validating aerodynamic design optimizations.

Preserving Decorative Cast Iron Panel Integrity

Biannual maintenance using specialized alkaline cleaners (pH 9.5-10.2) prevents surface degradation. Accelerated aging tests demonstrate that properly maintained coatings retain 89% of initial thickness after 15 years. Our 10-year protective warranty covers both structural defects and cosmetic deterioration, backed by ISO 1461 certification for hot-dip galvanizing processes.

(decorative cast iron panels)

FAQS on decorative cast iron panels

Q: What are common uses for decorative cast iron fence panels?

A: Decorative cast iron fence panels are ideal for enhancing security and aesthetics in residential or commercial properties. They're often used as garden borders, balcony railings, or perimeter fencing. Their intricate designs add timeless elegance to outdoor spaces.

Q: How do I maintain decorative cast iron panels?

A: Regularly clean panels with mild soap and water to remove dirt. Apply rust-resistant paint or sealant annually to prevent corrosion. Inspect for chips or cracks and repair promptly to ensure longevity.

Q: Can decorative cast iron panels be customized?

A: Yes, many manufacturers offer customization for patterns, sizes, and finishes. Clients can request bespoke designs to match architectural styles. However, custom orders may require longer lead times and higher costs.

Q: Are cast iron decorative panels difficult to install?

A: Installation requires basic DIY skills but can be labor-intensive due to the weight of cast iron. Proper anchoring with posts and concrete foundations is crucial. Professional installation is recommended for large or complex projects.

Q: What's the advantage of cast iron over other materials for decorative panels?

A: Cast iron offers superior durability and classic ornamental detail compared to aluminum or wood. It withstands harsh weather conditions better than most alternatives. Though heavier, its longevity often justifies the initial investment.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters