Feb . 14, 2025 10:52

Back to list

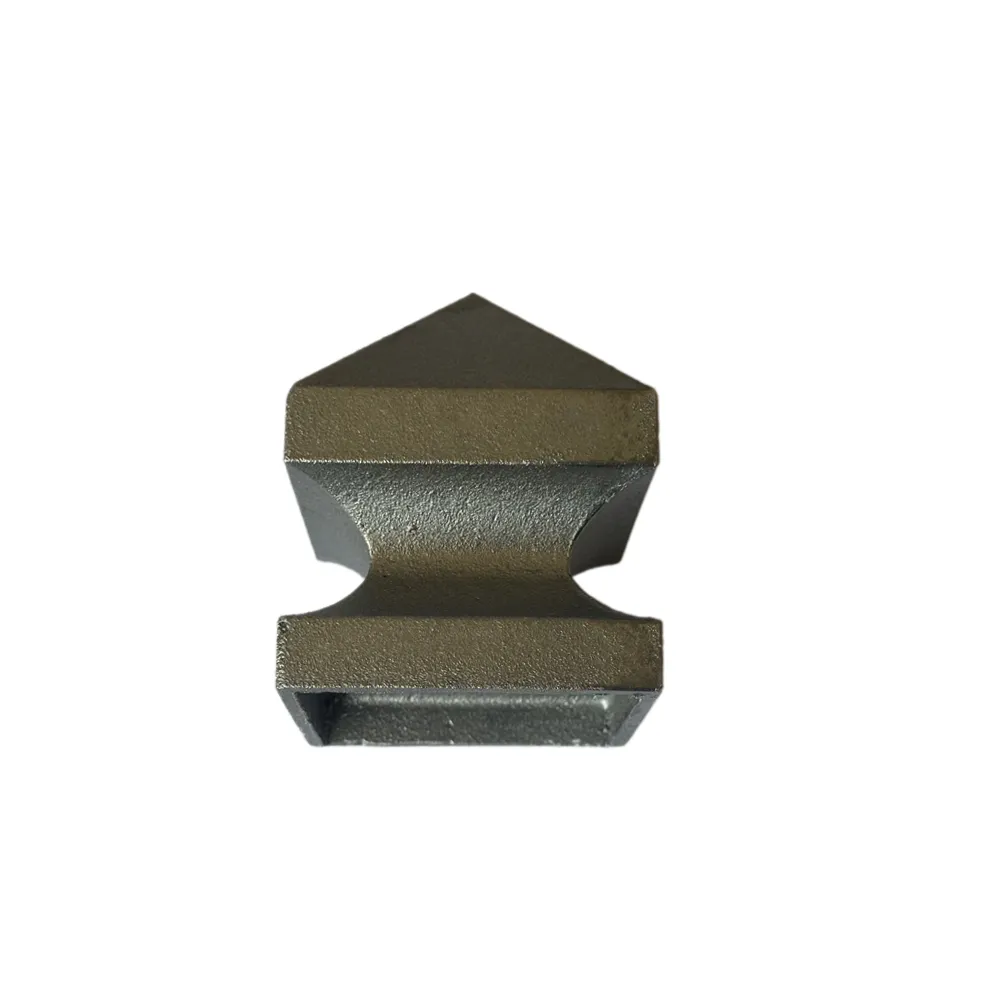

spear metal

Spear metal, a term often related to both traditional weaponry and modern engineering materials, has piqued interest across various industries. Leveraging advanced metallurgy, this concept merges historical craftsmanship with cutting-edge technology, offering remarkable potential in both fields of interest.

The field of medicine is also moving forward with the application of spear metal in surgical instruments and devices. Its biocompatibility and strength make it suitable for implants and prosthetics, promising improved outcomes in surgical procedures. Researchers are exploring spear metal’s potential in creating next-generation implants that integrate seamlessly with human tissue, offering a glimpse into future possibilities in medical innovations. Authoritativeness concerning spear metal derives from extensive research and documented case studies across different sectors. Publications in peer-reviewed journals detail numerous tests and assessments underscoring the metal's performance under varied conditions. These studies serve as authoritative sources, providing assurance of spear metal’s capabilities and its growing adoption. Trustworthiness hinges on consistent performance and reliability, given spear metal’s transformative role in crafting products that are critical to functionality and safety. Established manufacturers prioritize rigorous quality control procedures to certify that spear metal products meet predefined specifications. ISO certifications and compliance with international standards further reinforce the trust clients place in these products. In innovation-centric industries, adopting spear metal often marks a shift to more sustainable practices. Its development processes increasingly incorporate recycled materials, aligning with global sustainability goals and reducing carbon footprints. Trust is not only about the material’s performance but also its contribution towards achieving a sustainable future. To conclude, the modern conceptualization of spear metal encapsulates a confluence of ancestral wisdom and contemporary scientific advances, resulting in a highly adaptable material with diverse applications. Navigating through the lenses of experience, expertise, authoritativeness, and trustworthiness, spear metal stands as a testament to the dynamic nature of metallurgical progression, poised to play an integral role in future technological advancements and product innovations.

The field of medicine is also moving forward with the application of spear metal in surgical instruments and devices. Its biocompatibility and strength make it suitable for implants and prosthetics, promising improved outcomes in surgical procedures. Researchers are exploring spear metal’s potential in creating next-generation implants that integrate seamlessly with human tissue, offering a glimpse into future possibilities in medical innovations. Authoritativeness concerning spear metal derives from extensive research and documented case studies across different sectors. Publications in peer-reviewed journals detail numerous tests and assessments underscoring the metal's performance under varied conditions. These studies serve as authoritative sources, providing assurance of spear metal’s capabilities and its growing adoption. Trustworthiness hinges on consistent performance and reliability, given spear metal’s transformative role in crafting products that are critical to functionality and safety. Established manufacturers prioritize rigorous quality control procedures to certify that spear metal products meet predefined specifications. ISO certifications and compliance with international standards further reinforce the trust clients place in these products. In innovation-centric industries, adopting spear metal often marks a shift to more sustainable practices. Its development processes increasingly incorporate recycled materials, aligning with global sustainability goals and reducing carbon footprints. Trust is not only about the material’s performance but also its contribution towards achieving a sustainable future. To conclude, the modern conceptualization of spear metal encapsulates a confluence of ancestral wisdom and contemporary scientific advances, resulting in a highly adaptable material with diverse applications. Navigating through the lenses of experience, expertise, authoritativeness, and trustworthiness, spear metal stands as a testament to the dynamic nature of metallurgical progression, poised to play an integral role in future technological advancements and product innovations.

Prev:

Next:

Latest news

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters