Understanding the Corrosion Process of Wrought Iron and Its Susceptibility to Rust Formation

The Rusting of Wrought Iron Understanding Corrosion and Its Implications

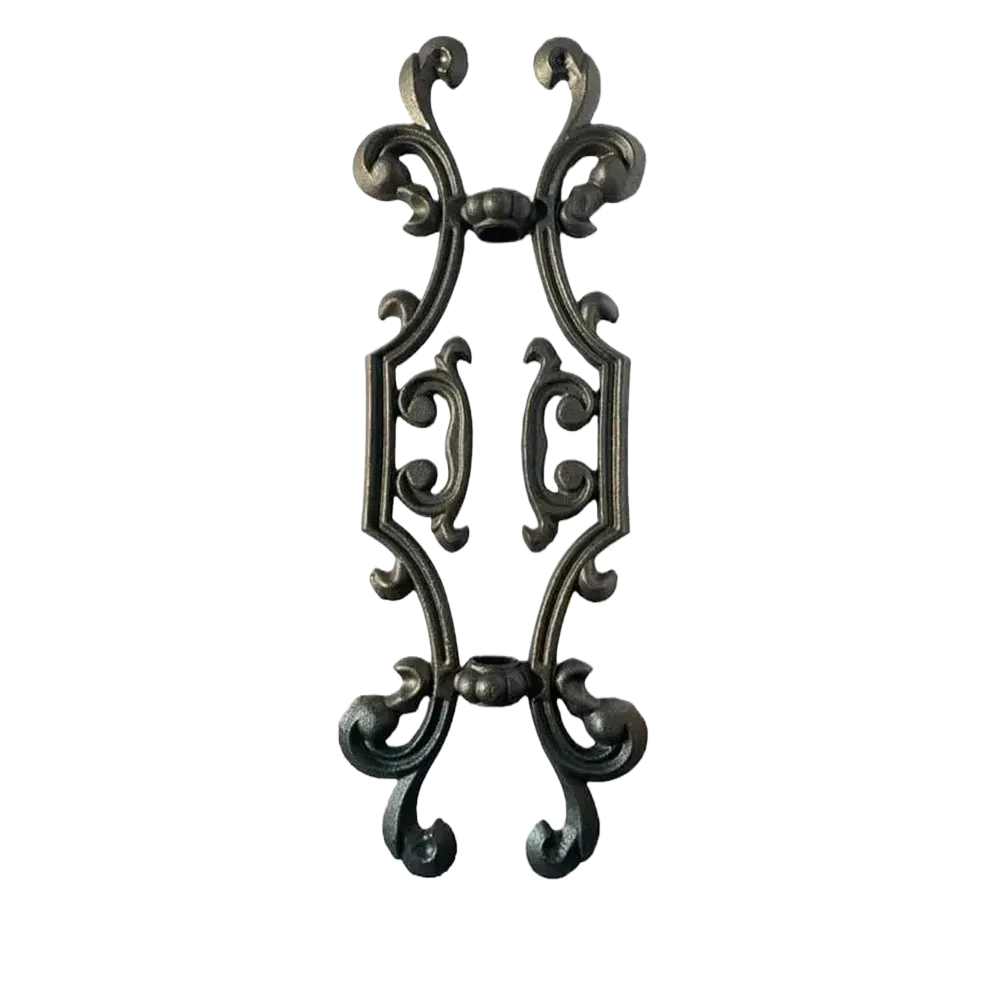

Wrought iron, known for its malleability and durability, has been a prevalent material in construction and manufacturing for centuries. However, despite its strength, wrought iron is susceptible to corrosion, particularly rusting. The rusting of wrought iron is a complex chemical process that can significantly affect its performance and lifespan, making it essential to understand the mechanisms behind it and the implications for various applications.

The Chemistry of Rusting

Rust is primarily composed of iron oxides, which form when iron reacts with oxygen in the presence of moisture. This oxidation process begins when iron atoms lose electrons, leading to the formation of positively charged iron ions. When moisture is present, particularly in the form of water or humidity, these iron ions can react with oxygen from the air, resulting in the formation of iron oxides, commonly referred to as rust.

The process is accelerated in the presence of salts and acids, which can significantly lower the pH of the environment, promoting further corrosion. When wrought iron is exposed to water, it creates a galvanic cell, facilitating electron transfer and leading to more rapid deterioration. This reaction not only depletes the structural integrity of the wrought iron but also leads to its unsightly appearance—an orange-brown layer covering the surface.

Factors Influencing Rusting

Several factors can influence the rate at which wrought iron rusts. One significant factor is the environmental conditions, including humidity, temperature, and the presence of pollutants. High humidity levels increase the likelihood of moisture interacting with the iron, thereby increasing the rate of corrosion. Similarly, elevated temperatures can accelerate chemical reactions, leading to faster rusting.

wrought iron rusting

Additionally, the chemical composition of the wrought iron itself plays a crucial role. Wrought iron contains small amounts of carbon and other elements. While these additions enhance its strength and workability, they can also influence its susceptibility to rust. The presence of impurities or inclusions can create localized areas of weakness, making certain spots more prone to corrosion.

Preventative Measures

To mitigate the rusting of wrought iron, several preventative measures can be implemented. The most common approach is the application of protective coatings, such as paint or galvanization. These coatings act as a barrier between the iron and moisture, thus reducing the risk of corrosion. Regular maintenance is also crucial; inspections and touch-ups can help ensure that protective layers remain intact.

Moreover, in environments where wrought iron structures are exposed to higher levels of moisture or salts, using rust-resistant alloys or treatments can be beneficial. This incorporation of rust-resistant materials can significantly prolong the life of wrought iron fixtures, especially those used in outdoor settings, such as bridges and railings.

Conclusion

Understanding the rusting of wrought iron is essential for maintaining its durability and aesthetic appeal. The chemical processes involved in corrosion can be accelerated by various environmental factors, leading to significant structural damage if not addressed. By employing preventive measures and conducting regular maintenance, the life expectancy of wrought iron can be significantly extended, ensuring that it continues to serve its purpose effectively. As we appreciate the historical significance and enduring beauty of wrought iron, it is essential to acknowledge and tackle the challenges posed by rusting to preserve its legacy for future generations.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters