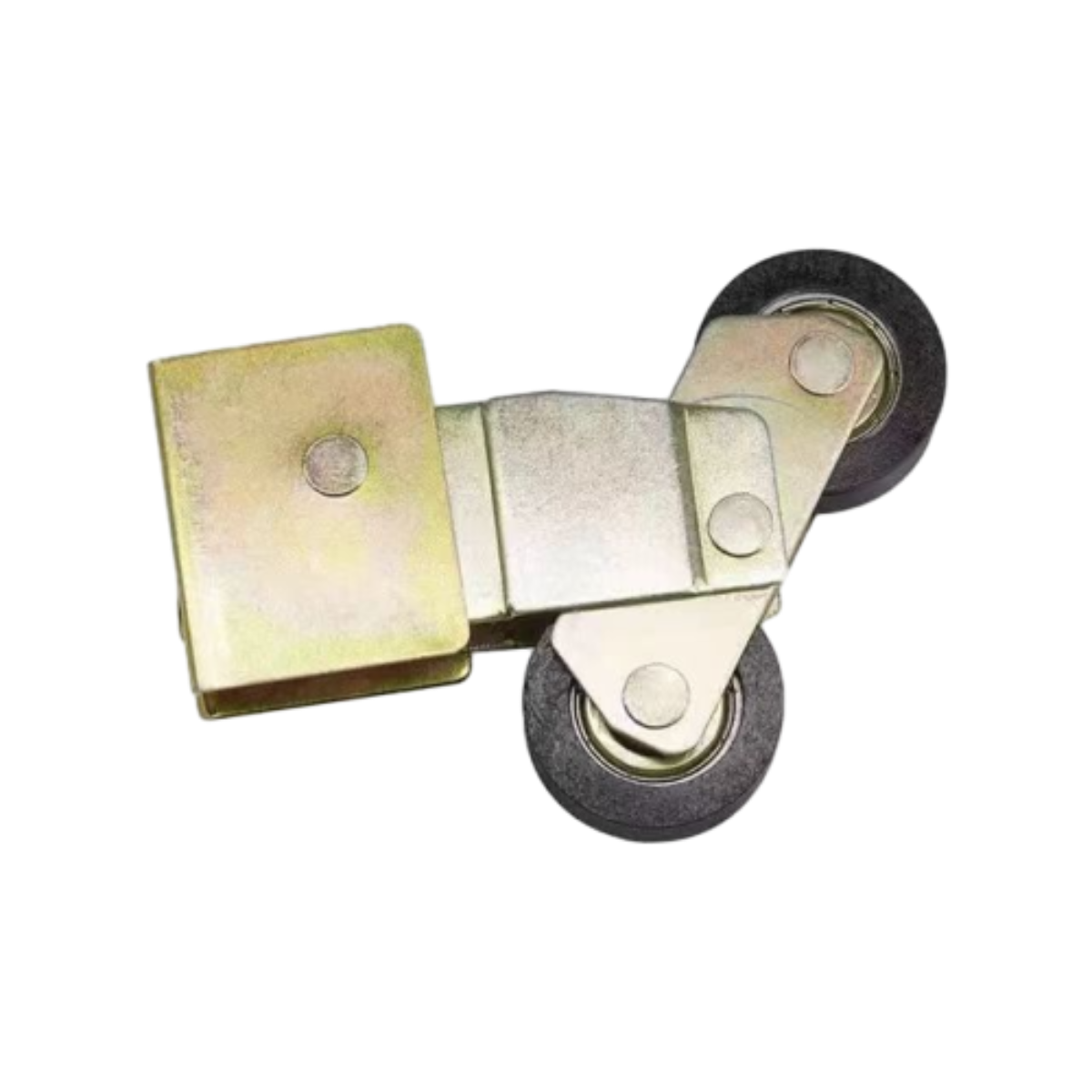

track door rollers

The Essential Guide to Track Door Rollers

Track door rollers are a crucial component of various sliding door systems, allowing for smooth and effortless operation. These rollers play a significant role in ensuring that doors open and close seamlessly, making them a vital aspect of both residential and commercial spaces. In this article, we will explore the types, functions, maintenance tips, and the importance of track door rollers.

Understanding Track Door Rollers

Track door rollers are typically made from durable materials such as nylon or steel, designed to support the weight of a sliding door while enabling movement along a track. They are situated at the top or bottom of the door frame and move within a dedicated track, helping to keep the door aligned and secure. There are various types of track door rollers, including top-mounted rollers and bottom rollers, each serving its own purpose and fit for specific door systems.

Types of Track Door Rollers

1. Nylon Rollers These are commonly used for residential sliding doors due to their quiet operation and resistance to corrosion. Nylon rollers glide smoothly along the track, providing a nearly silent experience when opening or closing the door.

2. Steel Rollers Generally found in heavier-duty doors, such as commercial-grade sliding doors, steel rollers are robust and designed for increased weight-bearing capacity. They provide enhanced durability and can withstand more wear and tear than their nylon counterparts.

3. Adjustable Rollers These rollers feature an adjustable mechanism that allows users to fine-tune the height of the door. This is particularly useful for maintaining alignment over time, as doors can settle and shift due to environmental factors.

4. Self-closing Rollers Often used in heavy-duty applications, these rollers can automatically pull the door closed after it has been opened, ensuring security and energy efficiency in settings such as warehouses and commercial buildings.

track door rollers

The Importance of Track Door Rollers

The significance of track door rollers cannot be overstated. Properly functioning rollers ensure that doors operate smoothly, minimizing wear on both the door and the track itself. They can also contribute to the overall aesthetic of a space; smooth-operating doors enhance the user experience and create a sense of quality and attention to detail.

Additionally, efficient sliding doors can aid in energy saving by providing a better seal when closed, reducing heating and cooling costs. In commercial settings, reliable sliding doors can facilitate high traffic flow while maintaining security and accessibility.

Maintenance Tips for Track Door Rollers

1. Regular Cleaning Dust, debris, and dirt can accumulate in the track and around the rollers, leading to decreased functionality. Regularly cleaning the track and rollers keeps them operating smoothly.

2. Lubrication Applying a suitable lubricant along the track and to the rollers can reduce friction and enhance the smooth operation of the door. Always check manufacturer recommendations for the appropriate type of lubricant.

3. Inspection Periodically check the rollers for signs of wear and tear, such as cracks or deformation. Early detection of damaged rollers can prevent larger, more costly issues down the line.

4. Realignment If a door begins to stick or doesn’t close properly, adjusting the roller height may be necessary to realign the door with the track.

In conclusion, track door rollers are a fundamental element for smooth and efficient door operation in various environments. Understanding their types, maintenance needs, and significance is essential for anyone looking to ensure functionality and longevity in sliding door systems. By paying attention to these aspects, you can keep your doors rolling smoothly for years to come.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters