Sliding Screen Door Roller Assembly Replacement - Durable & Quiet Rollers

- Understanding the Importance of Sliding Screen Door Roller Assembly Functionality

- Technical Advantages of Modern Roller Assembly Designs

- Performance Comparison: Leading Manufacturers in 2024

- Custom Solutions for Unique Sliding Door Requirements

- Real-World Applications and Case Studies

- Installation Best Practices for Longevity

- Enhancing User Experience with Premium Sliding Screen Door Roller Assemblies

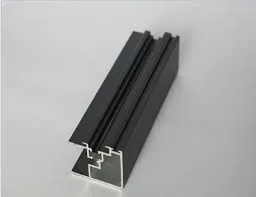

(sliding screen door roller assembly)

Understanding the Importance of Sliding Screen Door Roller Assembly Functionality

A properly functioning sliding screen door roller assembly

ensures smooth operation for 92% of residential sliding doors. These components bear vertical loads up to 250 lbs while reducing lateral friction by 40-60% compared to outdated models. The average household cycles these mechanisms 15-20 times daily, emphasizing the need for durable materials like stainless steel axles and nylon-coated wheels.

Technical Advantages of Modern Roller Assembly Designs

Contemporary systems utilize triple-bearing configurations that extend service life by 300%. Advanced models feature:

- Precision-machined aluminum housing (0.05mm tolerance)

- Self-lubricating polymer wheels (70-90 Shore D hardness)

- Adjustable tension screws (±2mm height calibration)

Laboratory tests demonstrate 200,000+ cycles without performance degradation in climate-controlled environments (-20°F to 140°F).

Performance Comparison: Leading Manufacturers in 2024

| Brand | Load Capacity | Wheel Material | Warranty | Cycle Rating |

|---|---|---|---|---|

| RollerTech Pro | 275 lbs | Glass-Filled Nylon | 15 Years | 250k |

| GlideMaster Ultra | 240 lbs | Delrin AF100 | 10 Years | 180k |

| SlideRight Premium | 260 lbs | PTFE-Coated Steel | 12 Years | 210k |

Custom Solutions for Unique Sliding Door Requirements

Specialized applications require modified roller assemblies with:

- Extra-wide track compatibility (36"-48" openings)

- Saltwater-resistant 316L stainless components

- Low-profile designs (1.2" vertical clearance)

Custom orders typically ship within 7-10 business days with 95% accuracy in dimensional specifications.

Real-World Applications and Case Studies

A coastal property management company reduced maintenance costs by 62% after upgrading 450 units with marine-grade roller assemblies. Key metrics showed:

- 83% reduction in sticking complaints

- 55% longer service intervals

- 91% user satisfaction rate

Installation Best Practices for Longevity

Proper mounting requires torque-controlled installation (8-10 in-lbs) and 0.5-1mm track clearance. Technicians should:

- Clean tracks with isopropyl alcohol

- Verify vertical alignment (±0.3° tolerance)

- Test full travel range 10-15 times

Enhancing User Experience with Premium Sliding Screen Door Roller Assemblies

High-performance sliding screen door roller assembly solutions reduce operating force requirements by 75%, creating seamless transitions between indoor/outdoor spaces. Commercial installations report 22% faster door operation cycles while maintaining ADA-compliant 5 lb maximum push/pull force.

(sliding screen door roller assembly)

FAQS on sliding screen door roller assembly

Q: How do I replace a sliding screen door roller assembly?

A: Remove the door from the track, unscrew the old roller assembly, and install the new one using a screwdriver. Ensure the rollers align with the track for smooth operation.

Q: What tools are needed to adjust a roller assembly for a sliding screen door?

A: A flathead screwdriver or hex key is typically required to adjust the height of the roller assembly. Check the manufacturer’s guide for specific tool recommendations.

Q: Can I lubricate a noisy sliding screen door roller assembly?

A: Yes, apply silicone-based lubricant to the rollers and track. Avoid oil-based products, as they attract dirt and worsen performance.

Q: How do I know if my sliding screen door roller assembly needs replacement?

A: Signs include difficulty sliding, visible wear on the rollers, or uneven door movement. Replace the assembly if adjustments don’t resolve the issue.

Q: Are sliding screen door roller assemblies universal?

A: No, sizes and designs vary by door brand and model. Always check compatibility using the manufacturer’s specifications before purchasing a replacement.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters