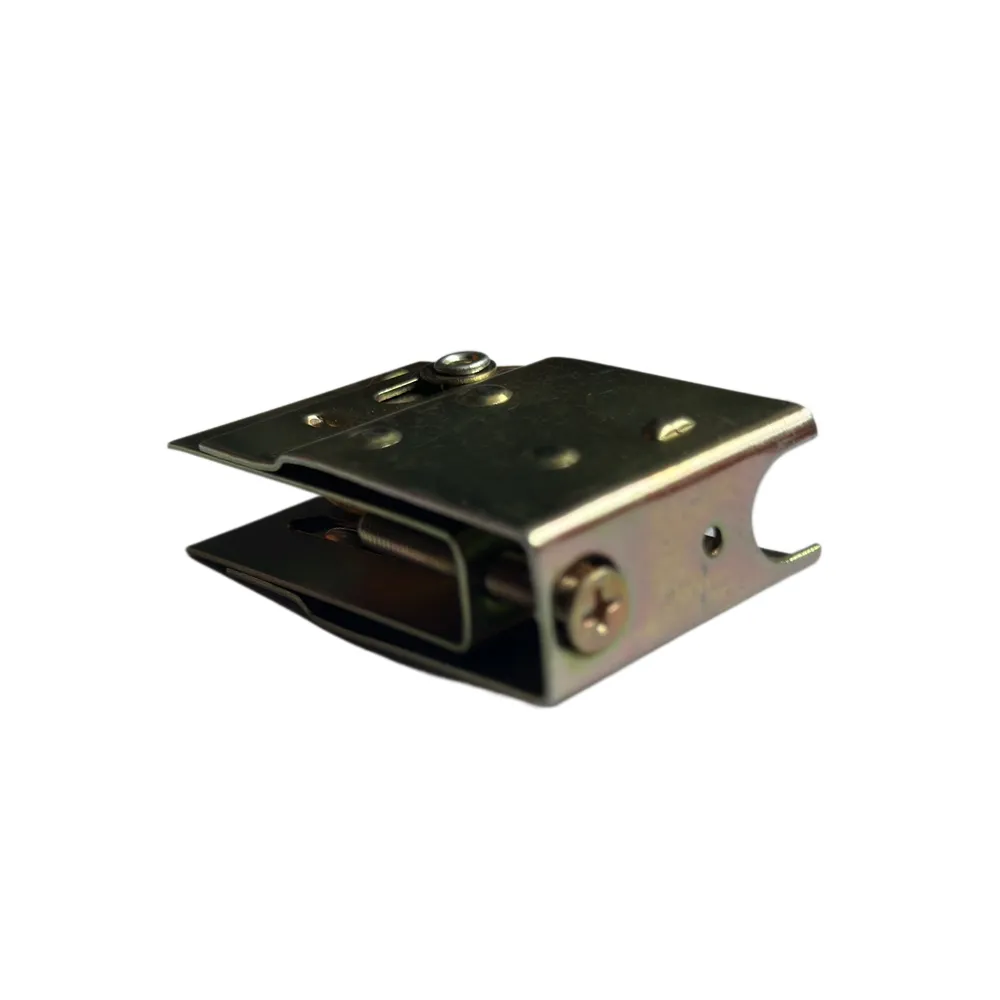

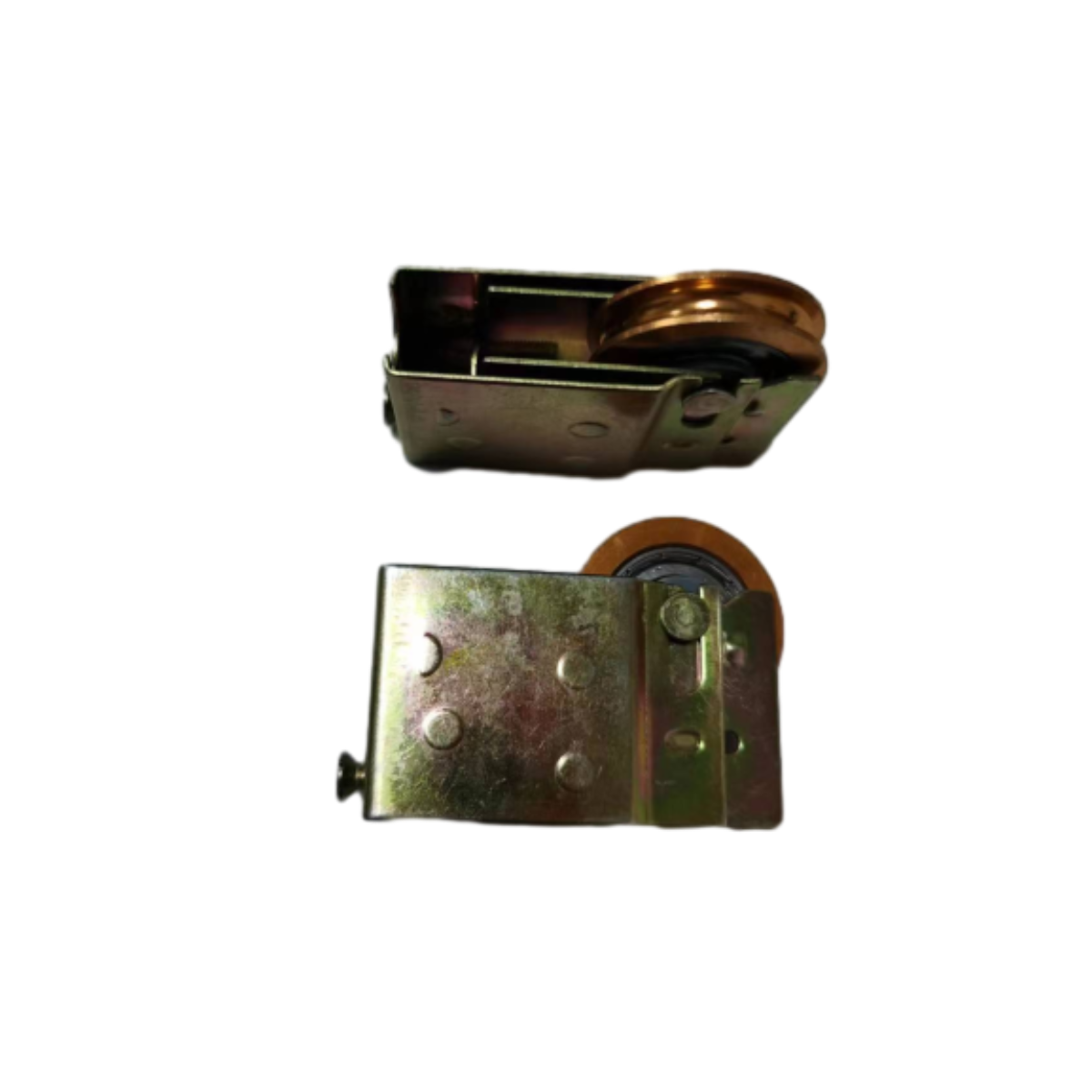

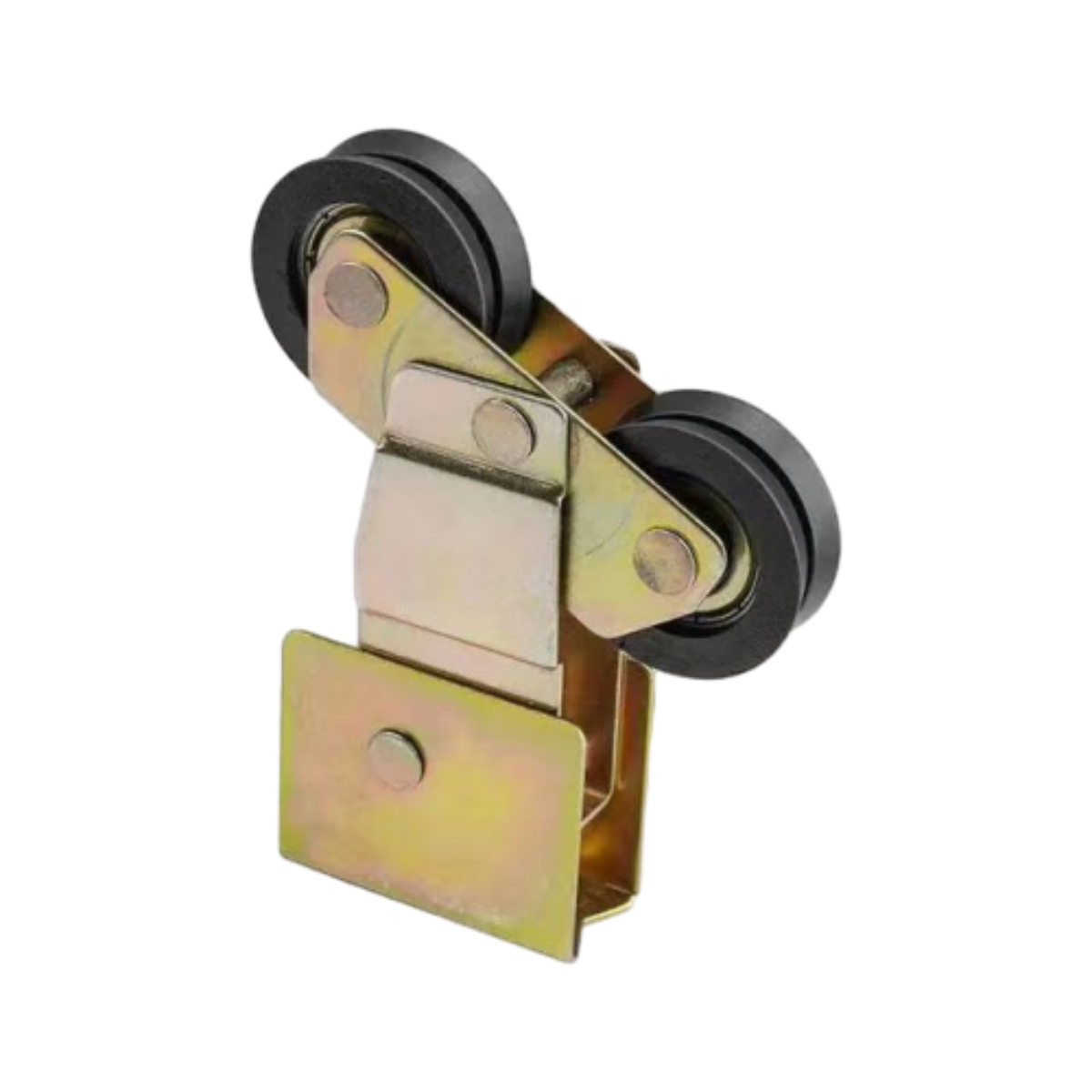

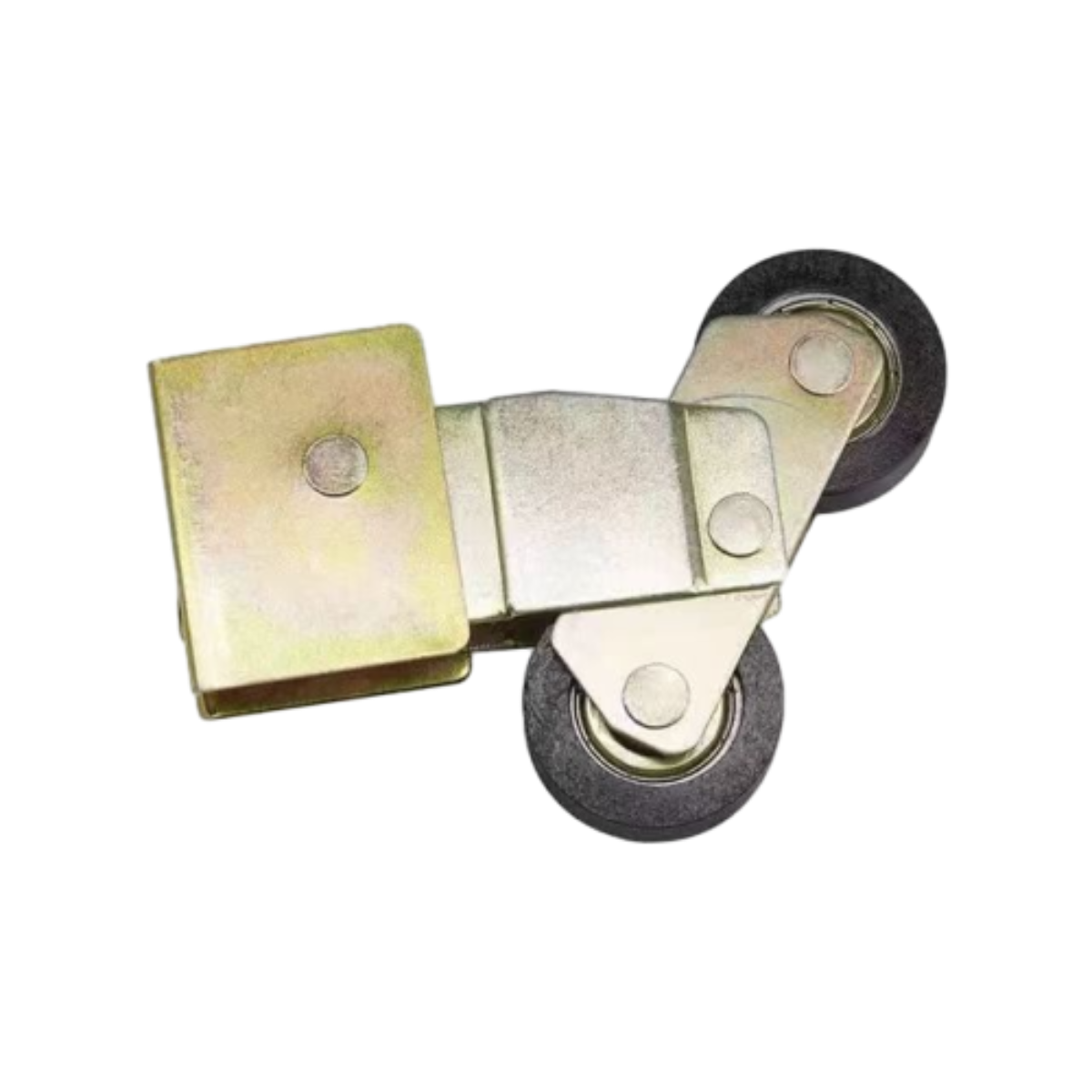

Sliding Roller: Smooth, Quiet, Durable, Easy Install

Sliding Roller Buyer’s Guide: Real-World Specs, Trends, and What Matters on Site

If you’re speccing a sliding roller for gates, garage doors, or farm doors, you already know the stakes: smooth travel, high load, and zero drama when it’s 2 a.m. and windy. Built in Shijiazhuang, Hebei Province, China, this unit is a workhorse door wheel fitting that reduces friction and keeps doors tracking cleanly. Many customers say the difference is “boringly reliable”—which is exactly what you want.

Industry trends I’m seeing

- Quieter movement: sealed bearings + polymer treads to damp vibration.

- Corrosion upgrades: hot-dip galvanizing and duplex coatings for coastal/agricultural sites.

- Higher load in smaller form factors: better metallurgy, tighter tolerances.

- Sustainability: longer service life and rebuildable hubs over “throwaway” wheels.

Key specifications (real-world focused)

| Parameter | Typical Value |

|---|---|

| Wheel diameter | 60–120 mm (custom up to 180 mm) |

| Groove profile | V, U, or flat track |

| Materials | Ductile iron or cast steel hub; nylon or steel tread options |

| Bearing | Double-sealed ball bearing, low-friction |

| Load rating (per wheel) | ≈ 200–600 kg (application-dependent) |

| Corrosion protection | Zinc plating, hot-dip galvanizing, or powder coat |

| Operating temp | -20°C to 80°C (real-world use may vary) |

| Service life | >100,000 cycles under EN 1527-style tests |

How it’s made (short version)

Materials are selected (ductile iron or cast steel hubs; optional nylon treads). Precision casting and CNC machining set the tolerances. Bearings are press-fitted with double seals. Surfaces get zinc plating or hot-dip galvanizing. QC includes dimensional checks, load testing per EN 1527, salt spray per ISO 9227, and wear trials (ASTM G99). I guess the headline is consistency—batch-to-batch stability matters.

Applications

- Farm and ranch gates; heavy yard gates

- Garage and industrial sliding doors

- Warehouse partitions; logistics bays

- Coastal/marine-adjacent doors (use galvanized option)

Users report the sliding roller stays quiet even after months of dust and rain. Not magic, just sealing and decent grease.

Advantages at a glance

- Low rolling resistance; less effort on long runs

- High load in compact form factor

- Corrosion-ready finishes for harsh sites

- Replaceable bearings; repair-friendly design

Vendor comparison (quick reality check)

| Vendor | Lead Time | Customization | Certs | Notes |

|---|---|---|---|---|

| TJJ Iron Casting (Hebei, CN) | ≈ 15–25 days | Groove, diameter, finish, bracket | ISO 9001; EN 1527-tested | Balanced price/performance |

| Generic Import House | 7–10 days ex-stock | Limited | Basic COA | Cheapest, variable QC |

| Premium EU Brand | 3–5 weeks | Broad | EN/CE/BHMA | Top finish, highest price |

Customization options

Dial in your sliding roller with: wheel Ø (60–180 mm), V/U/flat profile, sealed bearing grade (ABEC 1–3), zinc vs. hot-dip galvanized vs. powder, bracket/axle kits, and noise-optimized nylon tread. OEM/ODM available; samples ≈ 7–10 days.

Case study: farm gate retrofit

A 4.5 m steel farm gate in a coastal district swapped worn wheels for the sliding roller (galvanized, V-groove, 100 mm). Measured push force dropped ≈ 35%, and the client reported no binding after a wet season. Salt spray rating 480 h (ISO 9227) held up; grease inspections moved from monthly to quarterly. To be honest, that’s the kind of low-maintenance win ops teams love.

Compliance, tests, and data points

- Cycle testing >100k under EN 1527 protocol

- Salt spray: 240–480 h per ISO 9227 (finish-dependent)

- Wear trials: ASTM G99; bearing life estimated per ISO 281

- Factory QMS: ISO 9001; RoHS/REACH-compatible finishes available

Citations

- EN 1527:2019, Building hardware – Sliding door gear

- ISO 9227:2017, Corrosion tests in artificial atmospheres – Salt spray tests

- ANSI/BHMA A156.14, Sliding and Folding Door Hardware

- ASTM G99-17, Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus

- ISO 281:2007, Rolling bearings – Dynamic load ratings and rating life

-

Plough Wheel Cast Iron Material Enhances Load-BearingNewsNov.10,2025

-

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNewsNov.10,2025

-

Rubber Strip Shock Absorption Protects Window EdgesNewsNov.10,2025

-

Aluminum Profiles High Corrosion Resistance Suits Coastal AreasNewsNov.10,2025

-

Window Handle Aluminum Material Ensures Lightweight DurabilityNewsNov.10,2025

-

Sliding Roller Plastic Housing Fits Aluminum Sliding WindowsNewsNov.10,2025

-

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing -

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating -

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges