Hinge Manufacturer: Durable, Custom, Soft-Close, Heavy-Duty

Barrel Gate Hardware: Field Notes on a Workhorse

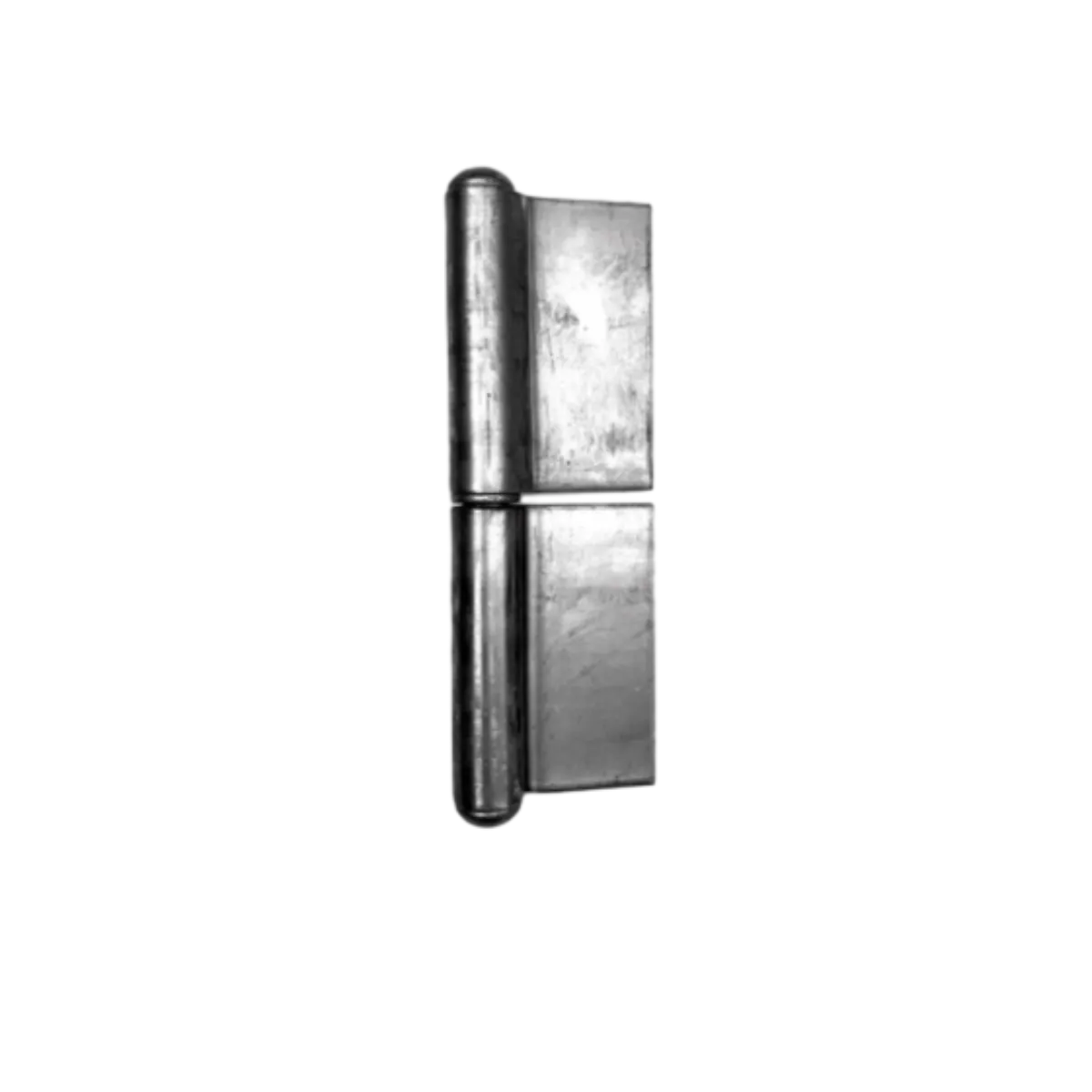

I’ve spent enough time around site gates and yard doors to know the quiet hero is often the Hinge. From farms to freight terminals, it’s the little metal pivot that decides whether your day goes smoothly or you wrestle with a sagging panel at 6 a.m. The model here originates in Shijiazhuang, Hebei Province, China, and—judging from shop-floor chatter—it’s built to take a hit.

What’s moving the market

The gate hardware segment is leaning into heavier loads, quieter operation, and coatings that shrug off coastal air. To be honest, we’re also seeing buyers ask for batch-level traceability and faster lead times. Surprisingly, even utility companies now specify salt-spray hours and cycle counts in tenders—once rare for something as humble as a Hinge.

Product snapshot and specs

This barrel-style Hinge is commonly used for steel gates, yard doors, and enclosure doors. It pairs ductile iron bodies with a hardened steel pin, which is a classic recipe for durability.

| Parameter | Typical Value (≈, real-world use may vary) |

|---|---|

| Material | Ductile iron body (ASTM A536 65-45-12); hardened carbon steel pin |

| Finish options | Hot-dip galvanized (ISO 1461), black powder coat, zinc-nickel |

| Load rating | ≈ 250–600 kg per pair (installation geometry dependent) |

| Opening angle | Up to 180°, depending on mounting |

| Salt spray (ISO 9227 NSS) | ≥ 240 h (powder), ≥ 480 h (galv.), lab-tested |

| Service life (cycles) | ≈ 100,000–200,000 cycles, tested to EN 1935-like method |

| Compliance | ISO 9001 plant; design verifies to EN 1935 concepts, ANSI/BHMA A156.1 |

How it’s made (and verified)

- Materials: ductile iron castings, 1045/4140 pin, optional brass/nylon bush.

- Methods: precision sand casting → heat treatment → CNC finish → galvanizing or powder coat → assembly.

- Tests: static load deflection, cycle test up to 200k; ISO 9227 salt spray; coating thickness via magnetic gauge; pin hardness via HRC.

- Service life: field installs report 5–10 years outdoors; coastal installs lean on galvanizing to hit the upper range.

- Industries: perimeter security, agriculture, logistics, utility substations, marina gates.

Where it works best

Use this Hinge for welded steel gates, heavy privacy doors, cage doors, and outdoor equipment enclosures. If you expect wind load or slamming (freight yards, I’m looking at you), spec the higher-load pin and galvanizing.

Customization choices

Pin diameter (±0.05 mm), grease nipple, anti-lift collar, and bespoke mounting lugs are common requests. Many customers say the factory’s willingness to tweak coatings by project—say, duplex (galv. + powder)—is the real differentiator.

Vendor comparison (what buyers actually ask)

| Vendor | Origin | Lead time ≈ | Customization | Certs | Price tier |

|---|---|---|---|---|---|

| TJ Iron Casting (factory) | Shijiazhuang, China | 20–35 days | High (pins, coatings, lugs) | ISO 9001; test to ISO 9227 | $ |

| Local OEM (weld shop) | Regional | 7–15 days | Medium (geometry only) | Varies | $$ |

| European brand | EU | 30–45 days | High | EN 1935, BHMA | $$$ |

Case notes from the field

Logistics yard, North China: after 14 months, the galvanized Hinge pair showed no red rust; cycle counter logged ≈ 60k. A coastal resort swapped to duplex coating—minor chalking after two summers, but movement remained smooth. Install crews like the grease nipple option; “less squeal, less call-backs,” as one foreman put it.

Quick install tips

- Align centerlines; a 2–3 mm shim can correct sag on wide gates.

- Weld in short beads, alternating sides, to minimize heat distortion.

- For coastal jobs, insist on ISO 1461 galvanizing or duplex finish.

References:

- ISO 1461: Hot dip galvanized coatings — Requirements and test methods. https://www.iso.org/standard/69082.html

- ISO 9227: Corrosion tests in artificial atmospheres — Salt spray tests. https://www.iso.org/standard/71231.html

- EN 1935: Building hardware — Single-axis hinges — Requirements and test methods. https://shop.bsigroup.com/products/building-hardware-single-axis-hinges-requirements-and-test-methods-en-1935

- ANSI/BHMA A156.1: Butts and Hinges. https://www.buildershardware.com/standards

-

Plough Wheel Cast Iron Material Enhances Load-BearingNewsNov.10,2025

-

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNewsNov.10,2025

-

Rubber Strip Shock Absorption Protects Window EdgesNewsNov.10,2025

-

Aluminum Profiles High Corrosion Resistance Suits Coastal AreasNewsNov.10,2025

-

Window Handle Aluminum Material Ensures Lightweight DurabilityNewsNov.10,2025

-

Sliding Roller Plastic Housing Fits Aluminum Sliding WindowsNewsNov.10,2025

-

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing -

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating -

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges