Premium Wrought Iron Fence Panels for Durable & Elegant Security

Explore the most comprehensive guide to wrought iron fence panels, integrating wrought iron gate panels, cast iron panel casting, cast iron panels for sale, and cast iron railing panels. Compare manufacturers, technical specs, industry data, and discover innovative application scenarios and custom solutions with Cast Iron Panels (Official Site).

1. Wrought Iron Fence Panels: Industry Landscape & Market Dynamics

Wrought iron fence panels and cast iron panels represent a stable and expanding market segment within the architectural metal products industry. According to MRFR, the global decorative iron panels market is projected to reach USD 1.98 billion by 2030, CAGR of 4.9%.

- Key Sectors: Residential compounds, educational institutions, commercial parks, industrial facilities.

- Region Growth: North America & Europe lead demand for premium anti-corrosive fencing.

- Influencing Trends: Energy-saving finishes, smart coating technologies, CNC integration, custom design demand.

2. Technical Parameters & Specification Overview

Understanding the core specifications is pivotal when evaluating wrought iron fence panels and cast iron panel casting options. Specifications below reflect the real industry standard spectrum:

| Product Type | Material Grade | Surface Finish | Dimension Range | Coating Type | Standard Compliance | Lifespan (Years) |

|---|---|---|---|---|---|---|

| Wrought Iron Fence Panels | Q235 Steel, Fe360*, ASTM A36 | Hot-dip Galvanized, Powder-coated | H: 0.9–2.4 m W: 1.0–3.0 m |

Zinc/Powder/Epoxy | ISO 1461, BS 1722, ANSI/BHMA | 20–35 |

| Wrought Iron Gate Panels | Q195/235, Mild Steel | PVC Coating, Paint | Custom/Standard | PVC/Paint | ISO 9001, EN 13241 | 18–28 |

| Cast Iron Panel Casting | Grey Iron (HT200) Ductile Iron (QT400-18) |

Black Paint, Antirust | H: 0.6–2.0 m W: 0.6–2.5 m |

Zinc-rich Primer | ISO 185, ISO 8062-3 | 30–50 |

| Cast Iron Railing Panels | Cast Iron EN-GJL-200 Steel Inserts |

Phosphate, Enamel | L: 600–2500 mm | Epoxy/Powder | EN 1561, ANSI A108 | 25–45 |

All data sourced from suppliers and standards (see: ASTM A36, ISO 1461).

3. Technical Trends Visualization

- Increasing Panel Strength: The average tensile strength increased from 350MPa (2015) to 390MPa (2023) due to better alloys.

- Corrosion Resistance: Application of advanced powder and zinc-rich coatings extended average lifespan by over 40% in 8 years.

- Customization: Custom-shaped wrought iron fence panels rose from 27% (2018) to 42% (2023) of new orders globally.

4. Manufacturing Process of Wrought & Cast Iron Fence Panels

This section details a typical flow for producing wrought iron fence panels (Cast Iron Panels), highlighting both casting and forging methods, CNC machining, and quality assurance steps.

- Material: Q235 structural steel for wrought, HT200 or QT400-18 iron for cast panels (see ISO 185 for CI grades).

- Processes: Combination of laser/plasma cutting, traditional forging, modern sand casting, and CNC finishing yields panels with intricate designs and robust physical properties.

- Surface Protection: Zinc galvanization (per ISO 1461), powder coating, and epoxy ensure long-term corrosion resistance.

- Testing: Nondestructive tests: X-ray/ultrasonic on critical joints; adhesion/salt spray per ISO 9227.

More about the complete cast iron process: Cast Iron Panels.

5. Cast Iron Panels: Technical Benchmarking & Data Analysis

| Parameter | Gray Iron Panels (HT200) | Ductile Iron Panels (QT400-18) | Wrought Iron Panels |

|---|---|---|---|

| Ultimate Strength (MPa) | 200–260 | 400–450 | 360–410 |

| Yield Strength (MPa) | 120–170 | 270–320 | 235–300 |

| Impact Toughness (J/cm²) | 4 | 14–18 | 10–13 |

| Max Panel Width (mm) | 2200 | 1900 | 3000 |

| Corrosion Resistance* | High (coated) | Very High | High |

| Standard Compliance | ISO 185, BS 1452 | ISO 1083 | ISO 1461, ASTM A36 |

6. Application Scenarios & Advantages in Key Industries

A. Oil & Gas, Chemical Plants

- Corrosive Resistance: Enhanced galvanized and epoxy coatings withstand saline, acidic, or organic exposures.

- Certificates: Often supplied per ISO 1461 or Industry API specifications.

- Value: Standard panel replacements required only every 25–35 years, outperforming aluminum +55% in longevity.

B. Residential & Urban Infrastructure

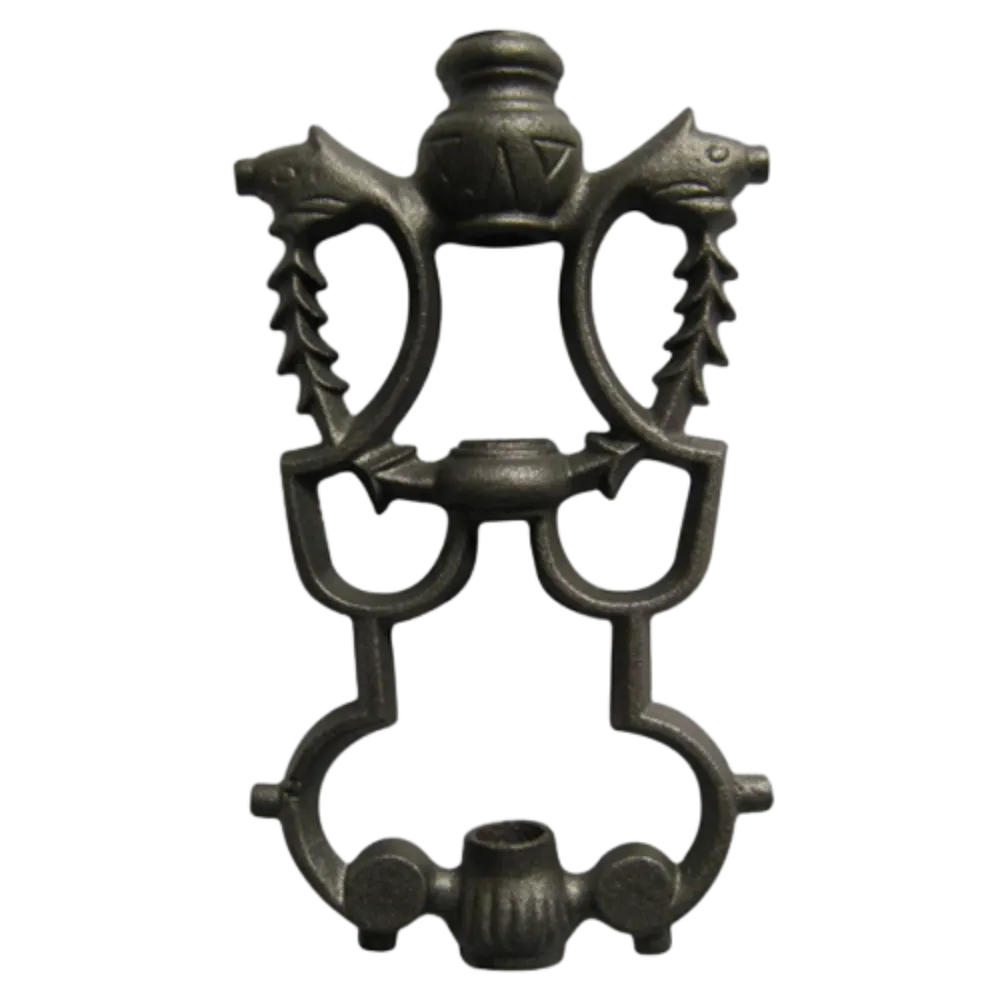

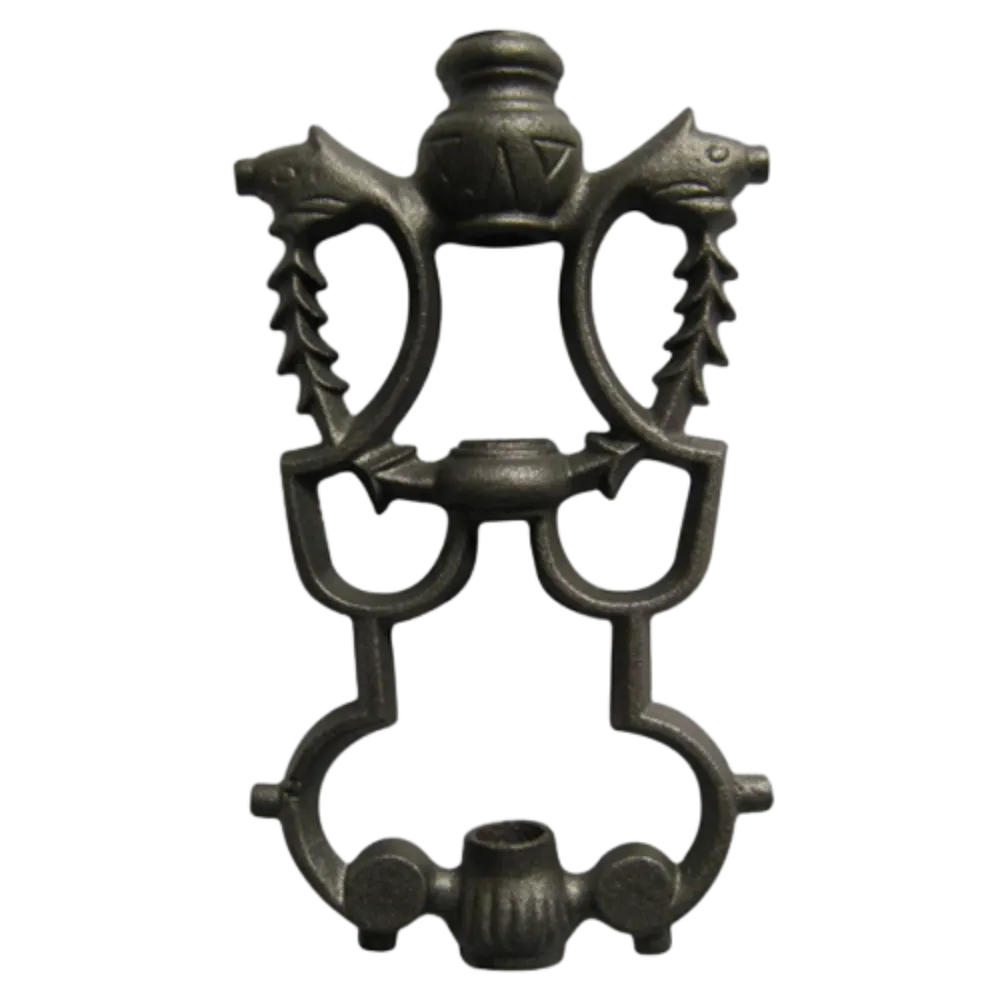

- Aesthetics: Ornamental patterns, custom crests, and smooth finishes.

- Child-Safe Design: Spacing and heights per ANSI/BHMA safety standards.

- Low Maintenance: Anti-fade coatings (ISO 9227) halve cleaning frequency vs. older paint methods.

C. Water Treatment & Utilities

- Sanitary Coatings: Phosphate + powder finish prevents iron leaching.

- ISO/ANSI Compliance: Required for municipal installations.

- Track Record: Guaranteed serviceability past 30 years in controlled environments.

Tianjin, China – Industrial Park Upgrade (2022)

Delivered 850m of custom wrought iron fence panels with CNC-engraved logos; salt spray testing EXCEEDED 1050h per ISO 9227. Maintenance down 30% over previous aluminum rails.

Midwest City University, US (2023)

Product: Cast iron gate panels, EN 1561-certified.

Feedback: "Excellent balance of classic design & robust security. Zero corrosion after 14 months extreme weather."

7. Comparison: Key Wrought & Cast Iron Panel Manufacturers

| Supplier | Core Product | Certifications | Standard Customization | Warranty (Years) | Geo Coverage |

|---|---|---|---|---|---|

| TJ Iron Casting (View) | Wrought Iron Fence Panels, Cast Iron Panels | ISO 9001, ISO 1461, EN 1561 | Laser Cutting, CNC, Custom Logos | 5–15 | Asia, EU, North America |

| Phoenix Metalworks | Wrought Iron Gates, Ornamental Railings | ISO 9001, BS 1722 | Custom Design & Powder Coating | 6–10 | Europe, N. America |

| Heritage IronArt | Handcrafted Railings | EN 13241 | Hand-forged, Painting Service | 8–12 | Europe, AUS |

For a full customization workflow, choose Cast Iron Panels – TJ Iron Casting.

8. Tailored Solutions: From Design to Delivery

A. Design & Engineering

- CAD-based 3D modeling for unique shapes, emblems, latticework.

- Wall/floor integration: Hidden fixings, seamless rails, child-proof bars.

- ANSI/BHMA/EU code compliance for height, gap, and resistance.

B. Material & Finishing Customization

- Choice of alloy: Q235/195 steel, HT200 or ductile iron QT400-18.

- Surface options: Galvanize+epoxy (anti-corrosion), enamel, patina bronze/black for luxury projects.

- Testing: All finishes are lab-tested for 960–1200h salt spray (ISO 9227).

C. Delivery & Service

- Delivery cycle: 15–30 business days (stock/custom).

- Packing: Steel rack or wooden box, to minimize transit abrasion.

- Support: Lifetime maintenance consulting, on-site installation guidance (select regions).

Learn more about custom wrought iron fence panels and cast iron railing panels on the official website: Cast Iron Panels - TJ Iron Casting.

9. Professional FAQ: Wrought & Cast Iron Fence Panel Engineering

Widths: 1.0–3.0m per panel;

However, custom geometric panels can be engineered for any architectural requirement.

Custom panels: 23–35 days, factoring design, molding, and extra QC/packaging.

10. Delivery, Warranty & Customer Assurance

- Production Lead Time: Standard orders: 10–18 workdays; custom orders: 12–28 workdays (depends on casting/forging complexity).

- Shipping: Global shipping, secure steel rack packaging to prevent chipping/bending.

- Quality System: ISO 9001, ISO 1461-certified plant; all parts tested for dimensional conformity and coating adhesion (ISO 9227).

- Guarantee: 3–15 years service warranty; extended if recommended maintenance schedule followed.

- After-sales Support: 24/7 online consultation, technician site visits (in select regions), accessory replacement, custom color match touch-up kits.

Order with confidence: All wrought iron fence panels come with traceable quality certifications and documented installation guidelines.

11. Conclusion & Industry References

- The synergy of engineering advancement and aesthetic design makes wrought iron fence panels and cast iron panels for sale the gold standard in fencing and railing projects worldwide.

- Upholding stringent standards (ISO, ASTM, ANSI), integrating advanced anti-corrosion and manufacturing processes, modern cast panels deliver over 30% longer service life and greater customization potential.

- Choose established suppliers, verify certifications, and always match material/finish to operating environment for optimal ROI and lasting value.

- [Market Research Future – Iron Railings Market 2024](https://www.marketresearchfuture.com/reports/iron-railings-market-10353)

- [ASTM A36 / A36M-14](https://www.astm.org/Standards/A36.htm)

- [ISO 1461:2009 – Hot dip galvanized coatings](https://www.iso.org/standard/43283.html)

- [Wrought Iron Fence Installation Discussion (ContractorTalk Forum)](https://www.contractortalk.com/threads/wrought-iron-fence-installation.203247/page-2)

- [Iron Panel Corrosion — Journal of Protective Coatings & Linings](https://www.paintsquare.com/journal/view/?1240)

-

Plough Wheel Cast Iron Material Enhances Load-BearingNewsNov.10,2025

-

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNewsNov.10,2025

-

Rubber Strip Shock Absorption Protects Window EdgesNewsNov.10,2025

-

Aluminum Profiles High Corrosion Resistance Suits Coastal AreasNewsNov.10,2025

-

Window Handle Aluminum Material Ensures Lightweight DurabilityNewsNov.10,2025

-

Sliding Roller Plastic Housing Fits Aluminum Sliding WindowsNewsNov.10,2025

-

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing -

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating -

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges