Anti-Corrosion on Window and Door Hardware

Window and door hardware—from window lock handle to windows roller and the brackets that pair with aluminium windows profiles—is the backbone of functional, long-lasting doors and windowssystems. However, exposure to rain, humidity, saltwater (in coastal areas), and harsh chemicals makes corrosion a major threat, leading to stuck handles, squeaky rollers, and premature hardware failure. For wholesalers serving clients in construction, hospitality, or residential sectors, anti-corrosion protection isn’t just a “nice-to-have”—it’s a necessity to ensure client satisfaction and repeat business. SHIJIAZHUANG TJJ TRADE CO.,LTD., a seasoned foundry and export company with over 20 years of experience, specializes in high-quality window and door hardware (alongside ornamental iron products) with robust anti-corrosion treatments. Trusted by clients worldwide, their hardware—paired seamlessly with aluminium windows profiles—is engineered to withstand harsh environments, making them a reliable partner for wholesalers seeking durable, low-maintenance solutions. This article explores key anti-corrosion techniques for window and door hardware, highlighting how to protect critical components like window lock handle and windows roller, and why TJJ Trade’s offerings stand out for long-term performance.

Anti-Corrosion Coatings for Window and Door Hardware

- Electroplating for Window Lock Handle: Window lock handle is one of the most used window and door hardware components, so its anti-corrosion coating must balance durability and aesthetics. TJJ Trade uses electroplating (zinc, nickel, or chrome plating) for window lock handle—a process that deposits a thin, uniform metal layer on the handle’s surface. Zinc plating provides excellent rust resistance (ideal for humid inland areas), while chrome plating adds a sleek, scratch-resistant finish that works well with modern aluminium windows profiles. For coastal clients, nickel-chrome plating offers extra protection against saltwater corrosion, ensuring the window lock handle remains smooth and functional for 10+ years. Wholesalers can note that this coating process is tested to meet international standards (e.g., ISO 1456), guaranteeing consistent performance across bulk orders.

- Powder Coating for Windows Roller: Windows roller(which enables smooth window sliding) needs a thick, impact-resistant anti-corrosion coating—TJJ Trade uses powder coating for this critical window and door hardware Powder coating involves applying a dry powder (polyester or epoxy) to the roller’s metal surface, then curing it at high temperatures to form a hard, seamless layer. This coating resists chipping, fading, and chemical damage, making it perfect for windows roller exposed to dirt, rain, or cleaning chemicals. When paired with aluminium windows profiles (which also use powder coating), the windows roller blends visually and offers matching corrosion resistance— a key benefit for wholesalers serving clients who prioritize cohesive, long-lasting window systems.

Material Selection for Corrosion-Resistant Window and Door Hardware

- Stainless Steel for Window and Door Hardware: TJJ Trade uses high-grade stainless steel (304 or 316) for core window and door hardware components like window lock handle mechanisms and windows roller Stainless steel contains chromium, which forms a protective oxide layer on the surface—this layer self-heals if scratched, preventing rust from spreading. 304 stainless steel works well for most inland applications, while 316 stainless steel (with added molybdenum) is ideal for coastal areas, as it resists saltwater corrosion 50% better than 304. Wholesalers can emphasize this material choice to clients: unlike carbon steel (which rusts quickly without coatings), stainless steel window and door hardware retains its strength and appearance with minimal maintenance.

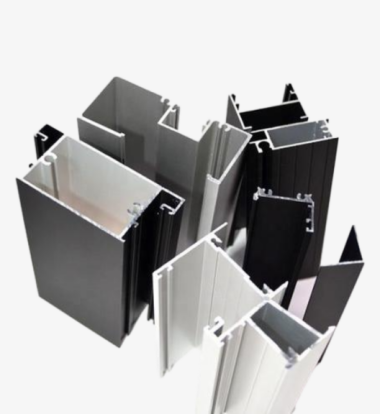

- Compatibility with Aluminium Windows Profiles: Aluminium windows profiles are naturally corrosion-resistant (thanks to their oxide layer), so TJJ Trade ensures their window and door hardware is compatible to avoid galvanic corrosion (a reaction between dissimilar metals). For example, when attaching window lock handle to aluminium windows profiles, they use plastic or rubber gaskets to separate the hardware from the aluminium—preventing metal-to-metal contact that can accelerate rust. Additionally, the hardware’s coatings (electroplating, powder coating) are formulated to match the aluminium windows profiles’ finish, ensuring no chemical reactions that damage either component. This compatibility is critical for wholesalers: it eliminates “compatibility headaches” for clients and extends the overall lifespan of the window system.

Anti-Corrosion Measures by Window and Door Hardware Type

|

Hardware Type |

Key Corrosion Threat |

Anti-Corrosion Solution |

TJJ Trade Advantage |

|

Window Lock Handle |

Frequent use + moisture ingress |

Electroplating (zinc/nickel-chrome) + sealed mechanism |

Smooth operation; rust-resistant internal parts |

|

Windows Roller |

Dirt buildup + rain exposure |

Powder coating + stainless steel bearings |

No squeaking; maintains sliding smoothness for years |

|

Aluminium Windows Profiles Brackets |

UV exposure + saltwater (coastal) |

Anodizing + powder coating double protection |

Matches hardware corrosion resistance; no discoloration |

|

Door Hinges (Window and Door Hardware) |

Weight pressure + humidity |

Stainless steel construction + grease-lubricated pins |

Supports heavy doors; no rust-related sticking |

Maintenance Tips to Extend Anti-Corrosion Life of Window and Door Hardware

- Regular Cleaning for Window Lock Handle and Windows Roller: Even with robust anti-corrosion treatments, window and door hardware benefits from regular cleaning to remove dirt, salt, or chemicals that can degrade coatings. TJJ Trade recommends wiping window lock handle with a damp cloth and mild soap monthly (avoid abrasive cleaners that scratch plating) and vacuuming windows roller tracks to remove debris (which can trap moisture and cause rust). For coastal clients, a monthly rinse with fresh water (to remove salt residue) is critical—this simple step extends the hardware’s anti-corrosion life by 30%. Wholesalers can share these tips with clients: low-effort maintenance ensures the hardware retains its performance and appearance.

- Lubrication for Moving Parts of Window and Door Hardware: Moving components like windows roller bearings and window lock handle latches need occasional lubrication to prevent friction damage to anti-corrosion coatings. TJJ Trade suggests using silicone-based lubricant (avoid oil-based lubricants, which attract dirt) every 3–6 months. Silicone lubricant is water-resistant, so it doesn’t wash away in rain, and it won’t degrade the hardware’s coatings. For example, lubricating windows roller bearings keeps them sliding smoothly, reducing wear on the powder coating and preventing rust from forming in crevices. This tip is especially valuable for wholesalers serving commercial clients (hotels, offices) with high-traffic doors/windows—minimizing maintenance calls and downtime.

Window and Door Hardware FAQS

Which Anti-Corrosion Treatment Is Best for Window Lock Handle in Coastal Areas?

For coastal areas, window lock handle from TJJ Trade should use nickel-chrome electroplating (over 316 stainless steel) for maximum saltwater resistance. Nickel-chrome plating forms a dense barrier against salt spray, while 316 stainless steel’s molybdenum content prevents pitting corrosion (a common issue with saltwater). Wholesalers can advise coastal clients to prioritize this combination— it ensures the window lock handle remains functional and rust-free for 15+ years, even in harsh marine environments.

Will Windows Roller’s Powder Coating Chip Over Time?

No—TJJ Trade’s windows roller uses high-quality polyester powder coating, which is baked at 180–200°C to form a hard, flexible layer that resists chipping. Unlike paint (which peels easily), powder coating adheres tightly to the roller’s surface and can withstand minor impacts (e.g., accidental bumps during window cleaning) without chipping. If the coating does get damaged (in rare cases of heavy impact), the underlying stainless steel prevents rust from spreading, so the windows roller still works. Wholesalers can assure clients that the powder coating’s durability matches the aluminium windows profiles’ finish.

Is Window and Door Hardware from TJJ Trade Compatible with All Aluminium Windows Profiles?

Yes—TJJ Trade’s window and door hardware is designed to be compatible with most standard aluminium windows profiles (e.g., 6063, 6061 aluminium alloys). The company provides detailed dimension charts and mounting templates for wholesalers, ensuring the hardware (window lock handle, windows roller, brackets) fits seamlessly with clients’ chosen profiles. For custom aluminium windows profiles, TJJ Trade offers tailored hardware solutions—adjusting bracket sizes or handle designs to match the profile’s specifications. This compatibility eliminates guesswork for wholesalers and their clients, streamlining installation.

How Often Should I Maintain Anti-Corrosion Coatings on Window and Door Hardware?

For most applications, window and door hardware needs maintenance every 3–6 months: clean with mild soap and water, lubricate moving parts (windows roller, handle latches), and inspect coatings for damage. Coastal areas require more frequent maintenance (monthly cleaning to remove salt residue), while inland, low-humidity areas can extend maintenance to 6–12 months. TJJ Trade provides a maintenance checklist for wholesalers to share with clients, making it easy to track upkeep. Following this schedule ensures the anti-corrosion coatings retain their effectiveness, extending the hardware’s lifespan by 50%.

Where Can Wholesalers Source High-Quality Anti-Corrosion Window and Door Hardware?

SHIJIAZHUANG TJJ TRADE CO.,LTD. offers a comprehensive range of anti-corrosion window and door hardware—including window lock handle, windows roller, and compatible brackets for aluminium windows profiles. With 20+ years of experience, strict quality control, and global export capabilities, their hardware is trusted for durability in diverse environments. Visit TJJ Trade’s website to explore product specs, request corrosion test reports, or discuss bulk ordering options—your one-stop shop for anti-corrosion window and door hardware that meets clients’ long-term performance needs.

-

Plough Wheel Cast Iron Material Enhances Load-BearingNewsNov.10,2025

-

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNewsNov.10,2025

-

Rubber Strip Shock Absorption Protects Window EdgesNewsNov.10,2025

-

Aluminum Profiles High Corrosion Resistance Suits Coastal AreasNewsNov.10,2025

-

Window Handle Aluminum Material Ensures Lightweight DurabilityNewsNov.10,2025

-

Sliding Roller Plastic Housing Fits Aluminum Sliding WindowsNewsNov.10,2025

-

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing -

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating -

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges