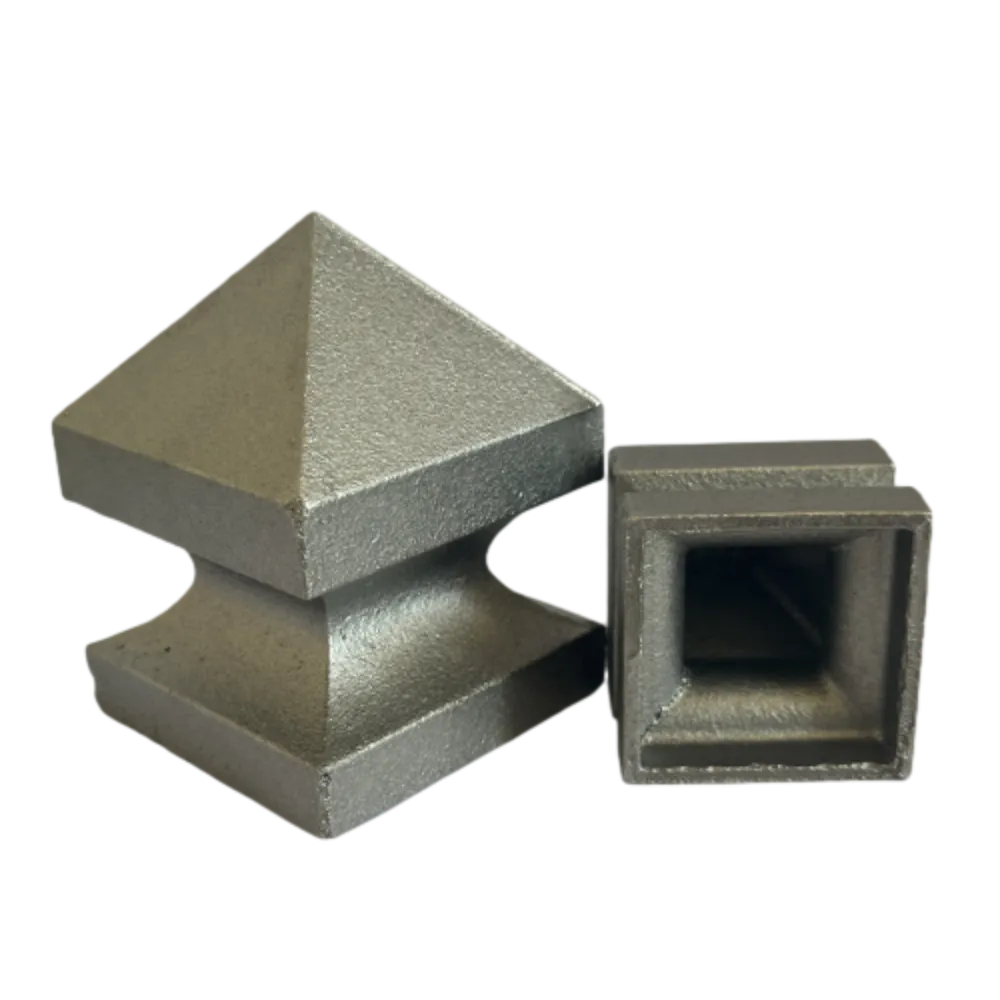

Iron Post Caps – Ornamental, Durable, Custom Fit

What to know about iron post caps in 2025

Walk past a well-kept fence and, if you notice the details (I do, habitually), the first thing that pops is the cap. It’s small, sure, but it pulls weight: keeps water out, adds style, and—oddly enough—tells you a lot about the maker. From Shijiazhuang, Hebei Province, China, the team behind the Ornamental Iron Post line has been moving fast on design and durability. And yes, iron post caps are having a moment—quietly, but unmistakably.

Industry trends I’m seeing

- Shift to dual-protection coatings: hot-dip galvanizing plus polyester powder, chasing 500–1,000 h salt-spray performance.

- Lean toward modular sizing (Φ65, Φ75, Φ85) to reduce inventory and speed installs.

- Custom color (RAL) orders rising—surprisingly heavy demand for deep matte blacks and coastal grays.

- More documented compliance: ISO 1461, ASTM B117, and ISO 9001 are increasingly table stakes.

Technical snapshot

Below are typical specs for caps that pair with the Ornamental Iron Post range (Φ65/75/85). Real-world use may vary, to be honest, depending on climate and installation.

| Parameter | Typical Spec (≈) |

|---|---|

| Fit sizes | Φ65, Φ75, Φ85 posts |

| Material | Cast iron or low-carbon steel (ASTM A36 equivalent) |

| Coating stack | HDG to ISO 1461 + polyester powder 60–90 μm (ISO 2808) |

| Salt-spray (ASTM B117) | ≥ 500 h standard; up to 1,000 h for coastal spec |

| Service life | 10–25 years depending on environment and maintenance |

| Fit tolerance | ±0.5–1.0 mm at the socket |

How they’re made (short version)

Materials arrive with mill certs; blanks are cast or press-formed, then machined, deburred, and shot-blasted. Galvanizing is done per ISO 1461; powder is applied via electrostatic guns and cured at ≈180–200°C. QC includes dimensional gauging, coating thickness (ISO 2808), cross-hatch adhesion (ASTM D3359), and salt-spray sampling per ASTM B117. It sounds dry, but that’s the map for iron post caps that don’t peel after the first winter.

Where they’re used

Residential fences, municipal railings, schools, hospitality patios, coastal boardwalks, farms—any post that needs water kept out and a clean finish. Many customers say the right iron post caps cut maintenance by simply stopping capillary water ingress at the tube end. Seems obvious; still overlooked.

Why they matter (advantages)

- Seals the post top; slows internal rusting dramatically.

- Aesthetics: pyramids, balls, or flat tops—your call.

- Safety: smoother ends; fewer snag points for clothing.

- Faster installs versus welded closures; field-replaceable.

Vendor comparison (quick look)

| Vendor | Coating/Standards | Customization | Lead Time | Notes |

|---|---|---|---|---|

| TJJ Iron Casting (Shijiazhuang) | HDG + powder; ISO 1461, ASTM B117; ISO 9001 | Sizes Φ65/75/85, RAL colors, logos | 15–25 days | Good fit tolerances; factory direct |

| Importer A | Powder only; partial documentation | Limited shapes | 30–45 days | Budget option; variable QC |

| Local Fabricator B | Paint; no galvanizing | Custom on request | 7–14 days | Fast, but shorter coating life |

Customization and options

Shapes: pyramid, ball, flat. Sizes: Φ65, Φ75, Φ85. Colors: RAL palette (AAMA 2604-type powders by request). Branding: light emboss logos. If your project needs bespoke iron post caps, expect a simple drawing review and a 3–5 day sample cycle.

Mini case files

Coastal boardwalk, Fujian: 1,000+ caps with HDG+powder, 1,000 h ASTM B117 protocol. After 18 months, inspectors reported “no blistering; minor chalking only.”

Boutique hotel, Texas Hill Country: Matte black pyramids on Φ75 posts. Manager note: “Installers shaved 20% time—no welding, clean fit.” That’s consistent with what I’ve heard elsewhere.

Final take

If you’re speccing iron post caps, look for the coating stack, the real test data, and a vendor who will show tolerances in writing. It’s not glamorous, but it’s what keeps fences looking new after the third rainy season.

Authoritative references

- ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

- ASTM D3359: Standard Test Methods for Rating Adhesion by Tape Test.

- AAMA 2604: Voluntary Specification for High Performance Organic Coatings on Architectural Aluminum (powder performance benchmark).

-

Plough Wheel Cast Iron Material Enhances Load-BearingNewsNov.10,2025

-

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNewsNov.10,2025

-

Rubber Strip Shock Absorption Protects Window EdgesNewsNov.10,2025

-

Aluminum Profiles High Corrosion Resistance Suits Coastal AreasNewsNov.10,2025

-

Window Handle Aluminum Material Ensures Lightweight DurabilityNewsNov.10,2025

-

Sliding Roller Plastic Housing Fits Aluminum Sliding WindowsNewsNov.10,2025

-

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing -

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating -

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges