Elegant Cast Iron Fence Decorations | Durable Panels & Ornaments

Introduction to Advanced Cast Iron Fence Decorations

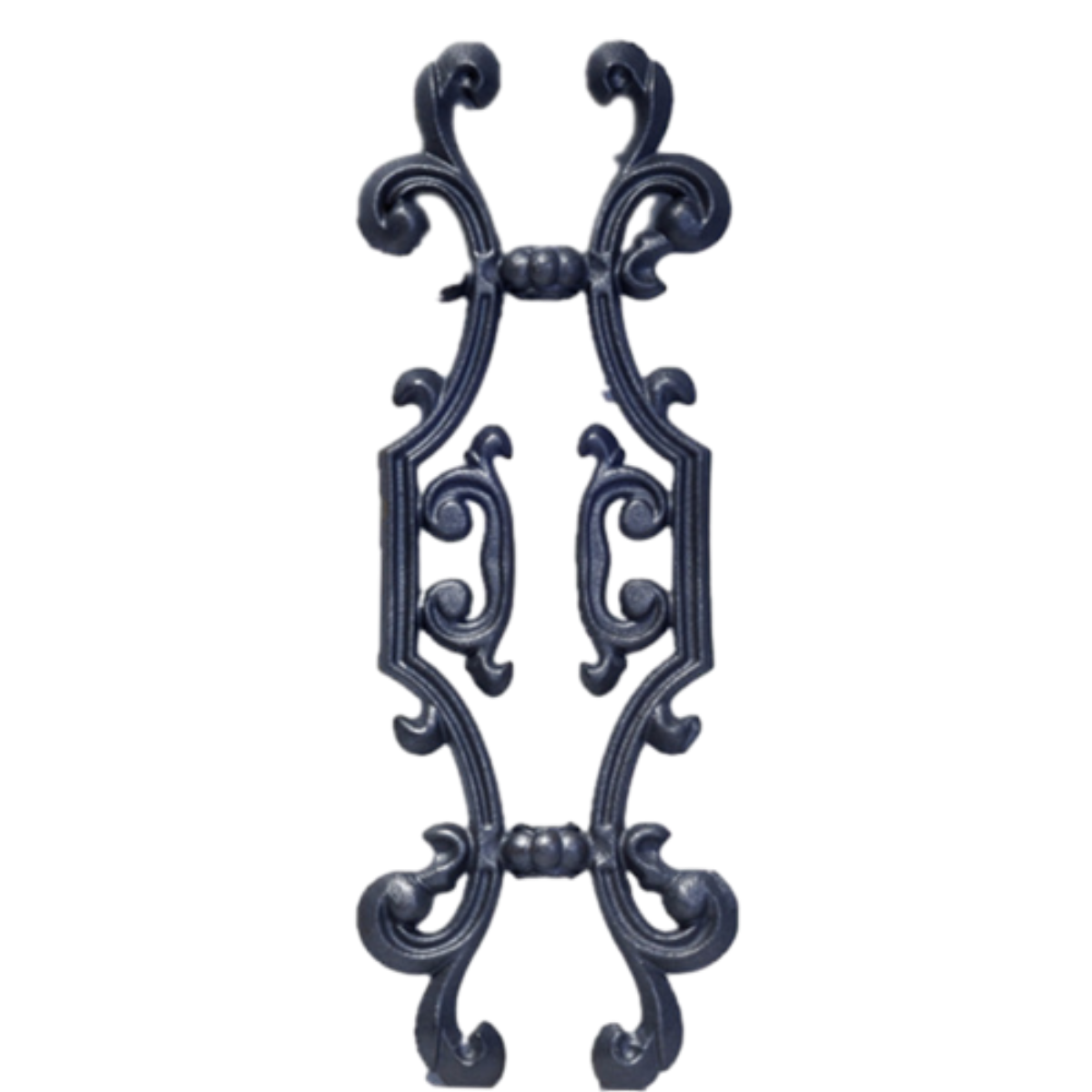

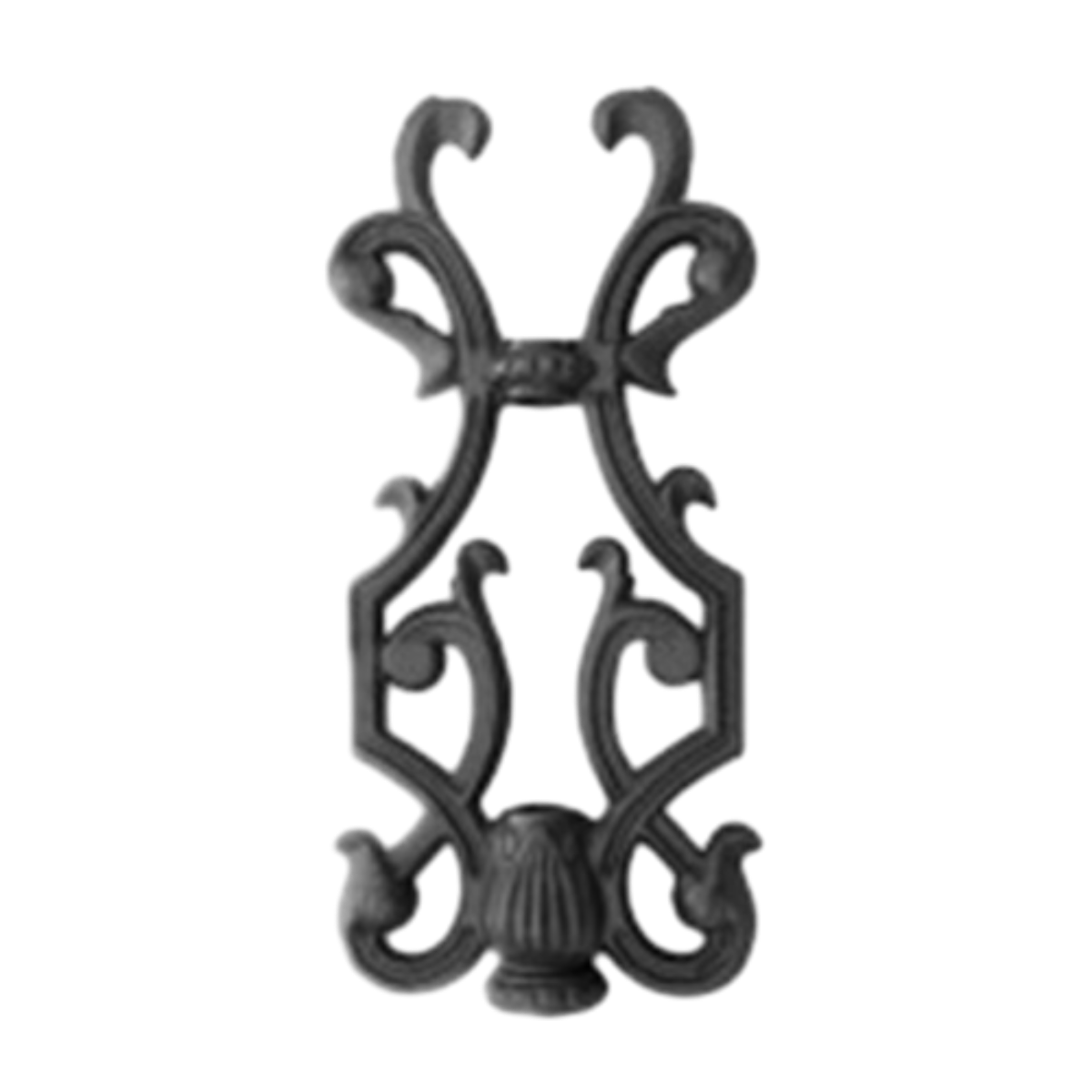

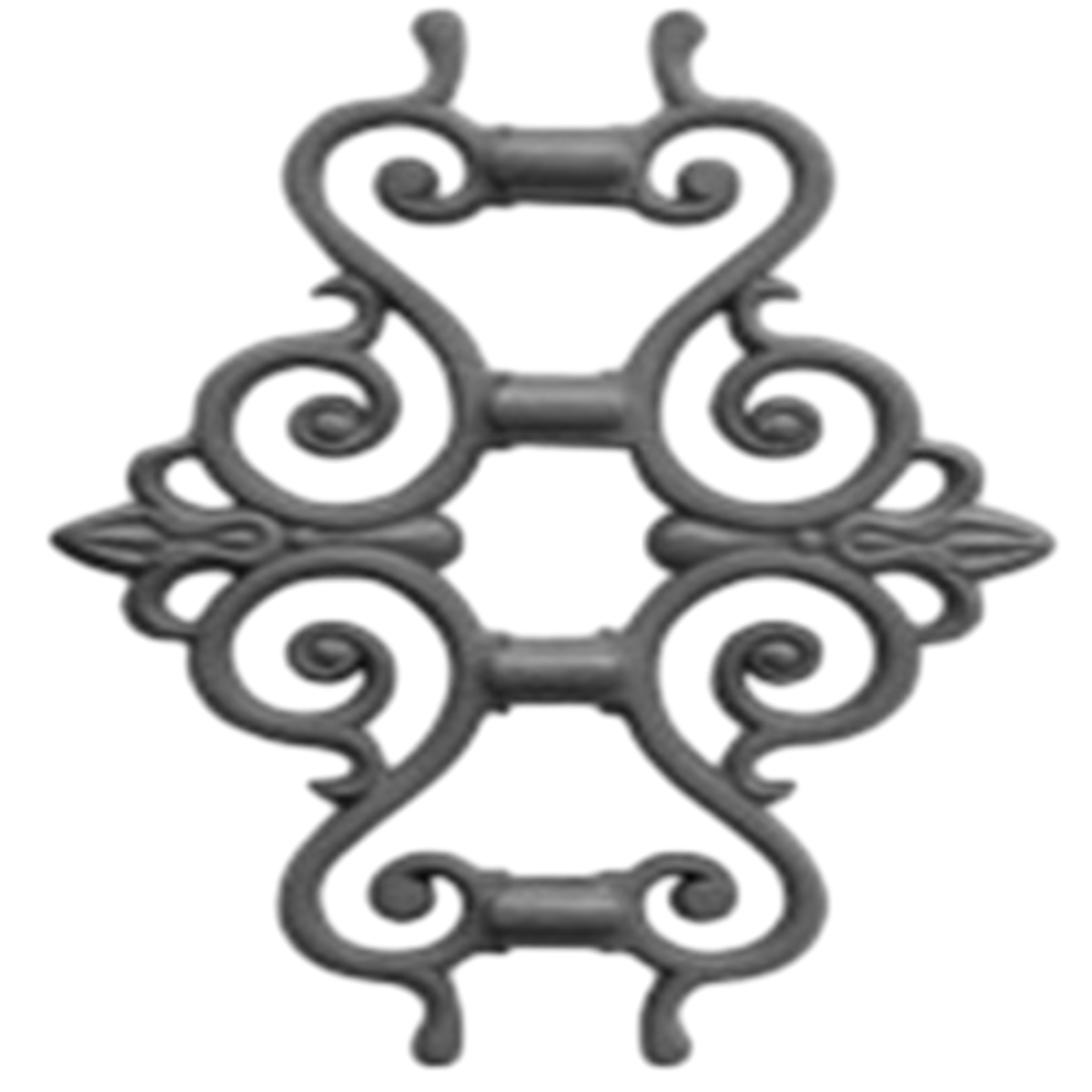

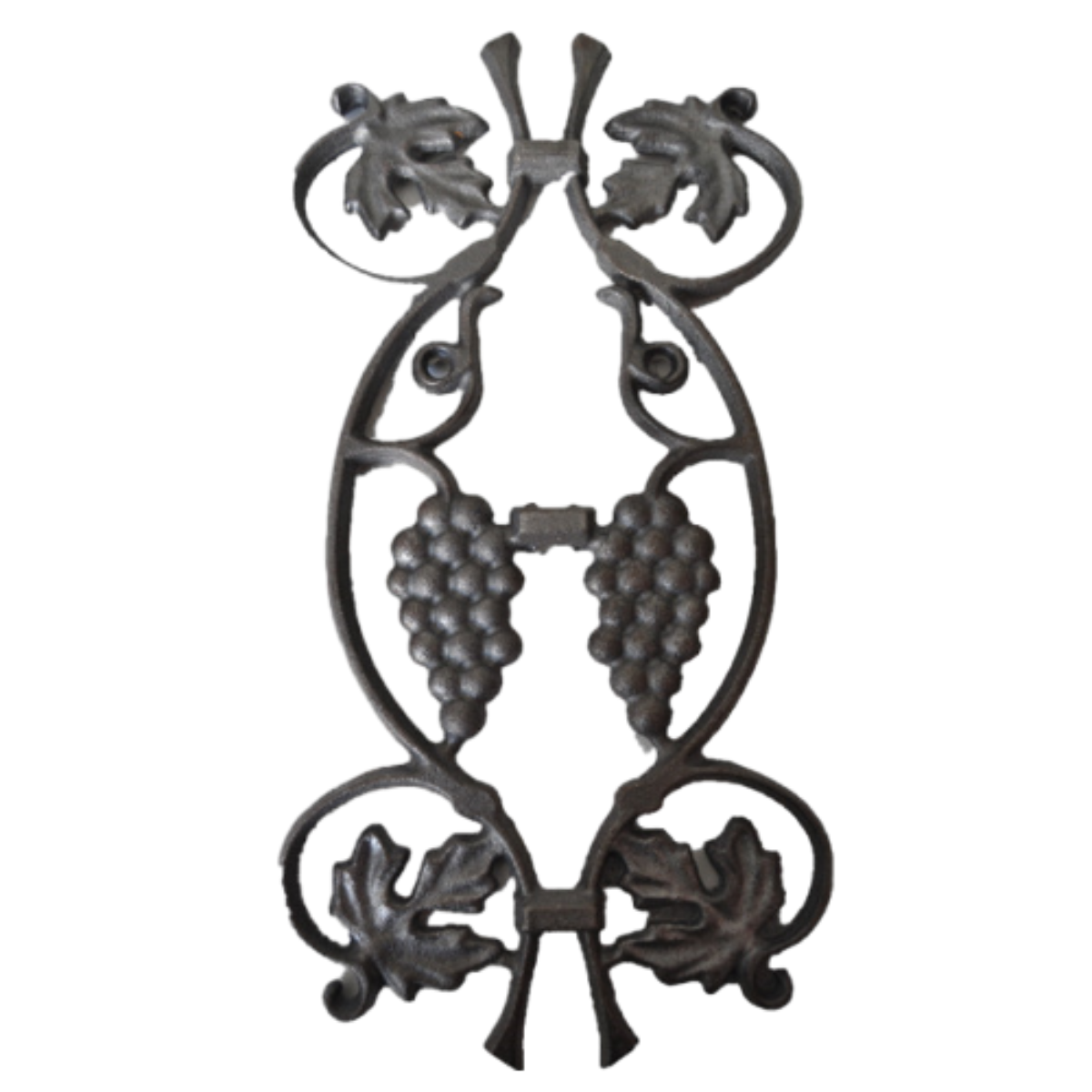

In the realm of architectural and industrial design, the demand for robust, aesthetically pleasing, and durable boundary solutions continues to escalate. Among the myriad options, cast iron fence decorations stand out as a premier choice, offering an unparalleled blend of classic elegance and engineering resilience. These intricate components are not merely functional barriers but serve as significant decorative elements, enhancing the prestige and security of properties across various sectors.

The industry for cast iron elements is currently experiencing significant growth, driven by increasing investments in infrastructure, urban development, and heritage preservation projects. Market analyses project a steady compound annual growth rate (CAGR) for ornamental metalwork, with cast iron components specifically favored for their longevity and low maintenance requirements. Key trends include a shift towards sustainable manufacturing practices, advanced finishing techniques for enhanced corrosion resistance, and sophisticated design customization enabled by modern casting technologies. Buyers in B2B markets, including construction firms, municipal entities, and large-scale industrial facility managers, are increasingly seeking suppliers capable of delivering high-precision, high-durability solutions that meet stringent technical specifications and aesthetic demands.

Furthermore, the integration of traditional casting techniques with contemporary design software allows for the creation of intricate cast iron fence ornaments that cater to bespoke architectural visions. This convergence ensures that while the material remains time-honored, its application is constantly evolving to meet modern aesthetic and structural requirements. The global market for architectural metalwork is estimated to reach over $100 billion by 2027, with cast iron components representing a substantial and growing segment due to their perceived value and inherent strength.

The Manufacturing Process: Precision in Cast Iron Panel Casting

The creation of high-quality cast iron fence decorations is a sophisticated metallurgical art, combining traditional craftsmanship with modern engineering precision. Our process ensures that each panel, ornament, or component meets rigorous quality and performance standards.

Detailed Process Flow:

- Design and CAD Modeling: The process begins with detailed conceptualization, often involving 3D CAD software (e.g., SolidWorks, AutoCAD). This allows for precise design iterations, stress analysis, and virtual prototyping of cast iron decorative panels, ensuring structural integrity and aesthetic fidelity.

- Pattern Making: A master pattern, typically made from wood, metal, or high-density plastic, is meticulously crafted based on the CAD design. This pattern dictates the final shape of the casting. Precision CNC machining is often employed for complex geometries to ensure dimensional accuracy.

- Molding: Sand molding is the predominant method. A sand mixture (silica sand, clay, water, and binders) is compacted around the pattern within a flask to create a mold cavity. For intricate designs, cores (internal sand shapes) are used to form internal features or hollow sections. The mold's permeability and strength are critical to prevent defects.

- Melting and Alloying: High-grade virgin iron ingots and carefully selected scrap are melted in induction furnaces, reaching temperatures often exceeding 1400°C (2550°F). Alloying elements such as silicon, manganese, and carbon are precisely controlled to achieve the desired material properties, typically ASTM A48 Class 30, 35, or ASTM A536 Grade 65-45-12 for ductile iron.

- Pouring: The molten iron is transferred from the furnace to ladles and then carefully poured into the prepared sand molds. The pouring temperature, rate, and mold-filling dynamics are critically monitored to prevent issues such as cold shuts, misruns, or entrapped gas.

- Cooling and Solidification: After pouring, the metal cools and solidifies within the mold. The cooling rate is vital in determining the microstructure and mechanical properties of the cast iron panel casting. Controlled cooling minimizes internal stresses and defects.

- Shakeout and Fettling: Once sufficiently cooled, the casting is removed from the sand mold (shakeout). Risers, gates, and runners (excess metal used to feed the casting during solidification) are then removed through processes like grinding, chipping, or plasma cutting. This stage is known as fettling.

- Heat Treatment (Optional but Recommended for Ductile Iron): For ductile iron, heat treatments such as annealing are often applied to optimize ductility, tensile strength, and impact resistance. This involves precise heating and cooling cycles.

- Machining and Finishing: Castings may undergo CNC machining for critical dimensions, drilling, or tapping if required. Surface preparation typically includes shot blasting to clean the surface and improve adhesion for coatings.

- Quality Control and Testing: Each batch undergoes stringent quality checks. This includes visual inspection for surface defects, dimensional checks using calipers and gauges, material analysis (spectroscopy), mechanical testing (tensile strength, hardness per ASTM E10), and non-destructive testing (NDT) such as ultrasonic or magnetic particle inspection if specified by the client. Compliance with ISO 9001:2015 for quality management is standard.

- Protective Coating and Packaging: Finished decorative railing panels are typically pre-treated (e.g., phosphating) and coated with corrosion-resistant finishes like powder coating, galvanization, or specialized paints (e.g., epoxy-based) to ensure a service life often exceeding 50 years even in harsh environments. They are then securely packaged for transit.

This meticulous process ensures that our products, from initial design to final finish, uphold the highest standards of durability, performance, and aesthetic appeal. Our target industries include petrochemical, metallurgy, water supply & drainage, and general construction, where our robust solutions offer exceptional corrosion resistance and a long service life, reducing lifecycle costs significantly.

Technical Specifications and Material Parameters

Understanding the intrinsic properties of cast iron and our manufactured panels is crucial for engineering and procurement professionals. Our Iron Gate Cast Iron Panels are engineered to deliver superior structural integrity and aesthetic value, adhering to international standards.

Key Material Properties (Typical for Gray Cast Iron, ASTM A48 Class 30):

- Tensile Strength: Min. 207 MPa (30,000 psi)

- Compressive Strength: Typically 690-1035 MPa (100,000-150,000 psi) – significantly higher than tensile strength, making it ideal for structural loads.

- Hardness: 170-220 HB (Brinell Hardness), providing excellent wear resistance.

- Modulus of Elasticity: 96-145 GPa (14-21 x 10^6 psi).

- Density: Approx. 7.15 g/cm³ (0.258 lb/in³).

- Corrosion Resistance: Excellent in many atmospheric environments due to the formation of a stable oxide layer; enhanced significantly with protective coatings.

Product Specification Table: Iron Gate Cast Iron Panels

| Parameter | Specification / Value | Standard |

|---|---|---|

| Material Grade | Gray Cast Iron (e.g., HT200, HT250) or Ductile Iron (QT450-10, QT500-7) | ASTM A48 / ASTM A536 / EN 1561 / EN 1563 |

| Panel Dimensions (Standard) | Customizable, typically ranging from 500x500mm to 1200x2000mm | Client-specific / ISO 2768-1 (Tolerance Class M) |

| Thickness (Structural Elements) | 8mm - 30mm, depending on design and load requirements | Engineering Design Calculations |

| Surface Finish Options | Powder Coating (RAL colors), Hot-Dip Galvanizing, Primer + Paint, Patina finish | ISO 12944 (Corrosion Protection), ASTM B117 (Salt Spray Test) |

| Tensile Strength (Gray Iron) | Min. 207 MPa (30,000 psi) for HT200 | ASTM A48 |

| Tensile Strength (Ductile Iron) | Min. 450 MPa (65,000 psi) for QT450-10 | ASTM A536 |

| Impact Resistance | Excellent (especially for ductile iron) | ASTM E23 (Charpy V-Notch) for Ductile Iron |

| Thermal Expansion Coefficient | Approx. 11.5 x 10^-6 /°C (6.4 x 10^-6 /°F) | Standard Material Data |

| Weight per unit area | Varies significantly by design and thickness (e.g., 20-100 kg/m²) | Calculated per design |

| Expected Service Life | 50+ years with proper maintenance and coating | Industry Standard / Empirical Data |

These parameters are meticulously controlled through our ISO 9001 certified quality management system, ensuring that every panel delivered meets or exceeds the specified requirements for demanding applications. Our expertise extends to tailor these specifications for unique project requirements, offering bespoke solutions for ornamental wrought iron fence panels and other custom architectural elements.

Application Scenarios and Target Industries

The versatility and inherent strength of cast iron make our decorative panels suitable for an expansive array of applications across various industries. From securing critical infrastructure to enhancing upscale architectural facades, the durability and aesthetic appeal of our products are consistently sought after.

Key Application Areas:

- Petrochemical and Energy Facilities: Robust fencing and security barriers for refineries, power plants, and chemical processing units. Our cast iron fence decorations provide not only perimeter security but also resilience against environmental stressors like high temperatures and chemical exposure, with specialized coatings further enhancing resistance.

- Metallurgy and Heavy Industrial Zones: Demarcation of hazardous areas, protective fencing around machinery, and robust architectural elements for industrial complexes. The high compressive strength of cast iron is particularly advantageous in these demanding environments.

- Water Supply & Drainage Infrastructure: Fences and gates for water treatment plants, pumping stations, and reservoirs. Resistance to moisture and various waterborne corrosive agents is paramount, making properly coated cast iron an excellent choice.

- Commercial and Public Buildings: Enhancing the aesthetic appeal and security of corporate campuses, government buildings, parks, and historical sites. Cast iron's ability to be cast into intricate designs allows for seamless integration with diverse architectural styles, from classic to contemporary.

- Residential and Estate Perimeters: Providing elegant and secure boundaries for high-end residential estates, private residences, and gated communities. The timeless beauty of cast iron fence ornaments significantly increases property value and curb appeal.

- Heritage and Restoration Projects: Replicating historical designs for period properties, museums, and conservation areas. Cast iron’s historical use and moldability make it ideal for faithful reproductions and sympathetic extensions to existing structures.

In these scenarios, our cast iron products excel by offering energy saving benefits through passive security and reduced lifecycle costs due to their exceptional longevity. The inherent strength of cast iron minimizes the need for frequent replacements or repairs, directly contributing to operational efficiency and sustainability goals for our clients. We work closely with engineers and project managers to specify custom solutions for each unique application, ensuring optimal performance and compliance with site-specific regulations.

Technical Advantages and Performance Metrics

The decision to specify cast iron for fence decorations and panels is underpinned by a multitude of technical advantages that directly translate into long-term value and superior performance. Our products are engineered for resilience, longevity, and aesthetic versatility, providing distinct benefits over alternative materials.

Core Technical Advantages:

- Exceptional Durability and Service Life: Cast iron boasts inherent material density and strength, making it highly resistant to impact, deformation, and wear. When properly coated, its service life can easily exceed 50-100 years, significantly outperforming lighter metals and composites. This longevity reduces replacement cycles and associated costs, offering a superior total cost of ownership (TCO).

- Superior Corrosion Resistance: While raw iron can rust, our finishing processes—including hot-dip galvanization (per ASTM A123/A153) and advanced powder coating (meeting AAMA 2605 standards for severe environments)—create a formidable barrier against environmental degradation. This engineered protection ensures resilience in coastal, industrial, and high-humidity climates.

- High Compressive Strength: Cast iron exhibits outstanding resistance to compressive forces, making it an ideal material for structural components that bear significant loads. This property contributes to the overall stability and robustness of fence systems.

- Aesthetic Versatility and Customization: The casting process allows for virtually limitless design intricacy, from historical patterns to modern, geometric motifs. This enables the creation of truly unique cast iron fence decorations that complement any architectural style and enhance property value. Our design team leverages advanced CAD/CAM to bring complex visions to life with precision.

- Low Maintenance Requirements: Thanks to their robust construction and protective coatings, cast iron fences require minimal maintenance beyond occasional cleaning. This translates into reduced operational expenses for property owners and facilities managers.

- Sustainability: Cast iron is a highly recyclable material, aligning with modern green building practices. Its extreme longevity also contributes to sustainability by minimizing waste and resource consumption associated with frequent replacements.

Material Comparison: Cast Iron vs. Alternatives

| Feature | Cast Iron | Wrought Iron (mild steel) | Aluminum | Vinyl/PVC |

|---|---|---|---|---|

| Durability & Strength | Excellent (high impact, compression) | Good (high tensile, can bend) | Fair (lighter, can dent) | Limited (brittle in cold, UV degradation) |

| Corrosion Resistance | Excellent with proper coating | Good with proper coating, susceptible to rust | Very Good (natural oxidation layer) | Excellent (inert to most chemicals) |

| Aesthetic Flexibility | Superior (intricate casting) | High (forging, bending) | Moderate (extrusion profiles) | Limited (molded, less detail) |

| Maintenance | Low | Moderate (periodic rust inspection/paint) | Low | Very Low (cleaning) |

| Weight | Heavy | Heavy | Light | Very Light |

| Cost (Initial) | Moderate to High (design complexity) | Moderate | Moderate | Low |

| Lifecycle Cost | Low (due to longevity, low maintenance) | Moderate | Low to Moderate | Moderate (due to potential for early replacement) |

This comparison highlights cast iron’s superior attributes for applications demanding both structural integrity and a refined aesthetic, particularly when considering long-term performance and investment return. The initial investment in cast iron fence decorations is often offset by decades of reliable service and minimal maintenance, proving it to be a cost-effective choice in the long run.

Vendor Comparison and Selection Criteria

Selecting the right vendor for cast iron fence decorations is a critical decision that impacts project timelines, budget, and long-term performance. B2B purchasers should evaluate potential suppliers based on a comprehensive set of criteria that go beyond mere price comparison.

Key Evaluation Factors:

- Quality Certifications and Compliance: Verify adherence to international quality management systems (e.g., ISO 9001:2015), material standards (e.g., ASTM, EN, DIN), and environmental regulations. Certifications from accredited bodies provide assurance of consistent product quality and process control.

- Manufacturing Capabilities and Technology: Assess the vendor's casting facilities, including furnace capacity, molding techniques (e.g., automated sand molding, CNC pattern making), and finishing capabilities (galvanization lines, powder coating booths). Advanced technology often indicates higher precision, efficiency, and broader customization options for cast iron decorative panels.

- Experience and Track Record: Look for vendors with a proven history in supplying cast iron components for similar projects or industries. Review case studies, client testimonials, and their years of operation. Long-standing expertise often translates to reliability and problem-solving capability.

- Customization and Design Support: A strong vendor should offer extensive customization options, including bespoke designs, material grades, and specialized finishes. Evaluate their design engineering team's ability to interpret complex specifications and provide value engineering suggestions.

- Supply Chain Reliability and Logistics: Evaluate lead times, production capacity, and logistics capabilities for on-time delivery. For international projects, understand their experience with customs, shipping, and global distribution networks.

- After-Sales Support and Warranty: Comprehensive warranty programs, accessible technical support, and clear policies for replacements or repairs are vital for long-term satisfaction and minimizing project risks.

- Pricing and Value Proposition: While cost is a factor, focus on the overall value proposition, including product quality, durability, customization, and support, rather than just the lowest initial price. A higher initial investment in a quality product from a reputable vendor often leads to lower lifecycle costs.

Our company prides itself on meeting and exceeding these stringent criteria, offering decades of experience, state-of-the-art manufacturing, and a dedicated team to support your project from concept to completion. We hold multiple international certifications and have successfully partnered with leading firms across diverse industries, underscoring our authority and trustworthiness in the market for ornamental wrought iron fence panels.

Customized Solutions for Decorative Railing Panels

One of the most significant advantages of choosing cast iron for architectural elements is the immense flexibility it offers in customization. Beyond standard designs, our manufacturing capabilities allow for the creation of unique, tailor-made decorative railing panels and fence components that perfectly align with specific project requirements and aesthetic visions.

Our Customization Capabilities Include:

- Bespoke Design Replication: Whether you have an existing historical design to replicate or a completely novel concept, our design engineers can transform your sketches, photographs, or CAD files into high-fidelity patterns and castings. This is particularly valuable for restoration projects where historical accuracy is paramount.

- Material Grade Selection: Depending on the application's structural and environmental demands, we can cast panels using various grades of gray cast iron (e.g., HT200, HT250) or ductile iron (e.g., QT450-10, QT500-7). Ductile iron offers superior tensile strength and impact resistance, ideal for areas subject to higher mechanical stress.

- Dimensional Tailoring: Panels can be cast to precise dimensions, eliminating the need for extensive on-site modifications. This includes custom heights, widths, and thicknesses to integrate seamlessly with existing structures or unique site layouts.

- Integrated Features: Custom casting allows for the integration of specific features such as mounting points, specialized joinery elements, or unique security enhancements directly into the panel design, ensuring a stronger, more cohesive final product.

- Advanced Finishing Options: Beyond standard powder coatings and galvanization, we offer a range of specialized finishes, including custom color matching (RAL, Pantone), multi-layer epoxy systems for extreme corrosion environments, and artistic patina treatments that mimic aged metal.

- Rapid Prototyping & Iteration: Utilizing modern CAD/CAM and advanced pattern-making techniques, we can provide rapid prototyping services for complex or critical components, allowing clients to review and approve designs quickly before full-scale production.

Our engineering team collaborates closely with architects, designers, and project managers from the initial concept phase through final production. This consultative approach ensures that all technical specifications, aesthetic requirements, and budget considerations are meticulously addressed, culminating in truly bespoke cast iron fence decorations that embody the client's vision and our commitment to excellence.

Application Case Studies and Customer Experience

Our commitment to quality and client satisfaction is best illustrated through real-world applications and positive customer feedback. We have a proud history of delivering high-performance cast iron fence decorations for demanding projects globally.

Case Study 1: High-Security Perimeter for a National Research Facility

Client: Confidential National Research Institute, Europe

Challenge: The facility required a robust, high-security perimeter fence that could withstand extreme weather conditions, deter unauthorized access, and maintain an aesthetically imposing presence without appearing overly militaristic. Traditional fencing solutions had failed to meet the long-term durability and low-maintenance requirements.

Solution: We designed and manufactured custom cast iron decorative panels using high-grade ductile iron (ASTM A536 Grade 65-45-12) with a specialized multi-layer epoxy coating for superior corrosion resistance. The design incorporated intricate patterns that subtly integrated security features, blending strength with sophistication. Panels were cast with integrated mounting points for easy and secure installation.

Outcome: The project was completed on schedule, spanning over 2 kilometers of fencing. The client reported significantly enhanced perimeter security, minimal maintenance needs over the initial five years, and high satisfaction with the product's aesthetic contribution to the facility's image. The durability of the ductile iron proved exceptional against minor impacts and environmental stressors.

Case Study 2: Historical District Restoration – Public Park Fencing

Client: Municipal Heritage Preservation Authority, North America

Challenge: To replace severely deteriorated fencing around a historical public park, requiring exact replication of intricate 19th-century cast iron designs while incorporating modern anti-corrosion treatments and ensuring structural integrity for public safety. Budget constraints mandated a solution with a low lifecycle cost.

Solution: Our team meticulously reverse-engineered the original fencing patterns using 3D scanning and CAD modeling to create new, precise patterns. We utilized gray cast iron (ASTM A48 Class 30) for historical accuracy and applied a hot-dip galvanization followed by a specialized architectural powder coating to achieve a finish that matched the historical aesthetic while providing maximum modern corrosion protection. We also provided detailed installation guidelines.

Outcome: The project was hailed as a successful blend of historical preservation and modern engineering. The municipality praised the faithful reproduction of the original designs and the robust quality of the new fencing. Public feedback highlighted the renewed elegance of the park. The projected service life of 70+ years significantly contributes to the city's long-term infrastructure planning and cost savings.

Customer Feedback Highlight:

"The quality of the cast iron panels we received for our industrial perimeter was exceptional. Their technical team's ability to customize to our specific load-bearing requirements and integrate seamlessly with our existing security systems was impressive. The durability has already proven itself against harsh environmental conditions, affirming our decision to invest in their products for long-term operational integrity." - Facilities Director, Major Petrochemical Plant.

Ensuring Trustworthiness: Frequently Asked Questions (FAQs)

To foster complete transparency and address common inquiries, we've compiled a list of frequently asked questions regarding our cast iron fence decorations and services.

Q1: What is the typical lead time for custom cast iron fence panels?

A1: Lead times vary depending on the complexity of the design, order volume, and current production schedule. For standard designs, production typically ranges from 4-6 weeks. Custom designs requiring new pattern development may extend this to 8-12 weeks from design approval. We provide a detailed project schedule upon order confirmation.

Q2: What kind of warranty do you offer on your cast iron products?

A2: We offer a comprehensive 10-year warranty against manufacturing defects and structural integrity failures under normal use and proper installation. Our specialized anti-corrosion coatings are typically warrantied for 5-7 years against chipping, peeling, or significant fading, dependent on environmental conditions and maintenance. Full warranty terms are provided with each quotation.

Q3: Can your cast iron panels be used in coastal or highly corrosive environments?

A3: Absolutely. For such demanding environments, we recommend hot-dip galvanization (conforming to ASTM A123/A153 for iron and steel products) followed by a high-performance powder coating (AAMA 2605 compliant). This dual-layer protection provides exceptional resistance to salt spray and atmospheric corrosion, ensuring prolonged service life.

Q4: What are the primary differences between gray cast iron and ductile iron for these applications?

A4: Gray cast iron (e.g., ASTM A48) is characterized by its excellent machinability, damping capacity, and high compressive strength, making it ideal for decorative elements where intricate detail and rigidity are important. Ductile iron (e.g., ASTM A536) offers significantly higher tensile strength, ductility, and impact resistance due to its spherical graphite structure. It is preferred for applications requiring greater resistance to bending, impact, or where structural loads are more demanding.

Lead Time & Fulfillment:

We operate with a robust supply chain and efficient production planning. Typical fulfillment for large projects involves phased deliveries, coordinated with your project schedule. Our logistics team manages domestic and international shipping, ensuring secure and timely delivery to your site. Expedited options are available upon request and feasibility assessment.

After-Sales Support:

Our commitment extends beyond delivery. We provide comprehensive after-sales support, including technical assistance for installation, maintenance guidelines, and prompt resolution of any product-related concerns. Our dedicated customer service team is available via phone and email to ensure your continued satisfaction.

Conclusion

The enduring appeal and technical superiority of cast iron fence decorations make them an indispensable choice for discerning B2B clients across diverse industries. From securing critical infrastructure to enhancing historical estates, our products offer an unmatched combination of durability, aesthetic flexibility, and long-term value. Through meticulous manufacturing processes, adherence to international quality standards, and a focus on customized solutions, we empower our clients to achieve their project goals with confidence.

Our expertise in cast iron panel casting ensures that every component not only meets but often exceeds the most stringent performance requirements, providing robust security, enduring beauty, and an impressive return on investment. As market trends continue to emphasize sustainable and high-performance materials, cast iron remains at the forefront, offering a timeless solution for modern challenges.

References

- American Society for Testing and Materials (ASTM). (Various standards: A48, A123, A153, A536, B117, E10, E23). Available at astm.org.

- International Organization for Standardization (ISO). (ISO 9001:2015, ISO 12944, ISO 2768-1). Available at iso.org.

- American Architectural Manufacturers Association (AAMA). (AAMA 2605 specification for superior performing organic coatings). Available at aamanet.org.

- ASM International. (Handbook Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys). Available at asminternational.org.

- Cast Metals Institute. (Principles of Metalcasting). Available at afsinc.org.

-

Plough Wheel Cast Iron Material Enhances Load-BearingNewsNov.10,2025

-

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNewsNov.10,2025

-

Rubber Strip Shock Absorption Protects Window EdgesNewsNov.10,2025

-

Aluminum Profiles High Corrosion Resistance Suits Coastal AreasNewsNov.10,2025

-

Window Handle Aluminum Material Ensures Lightweight DurabilityNewsNov.10,2025

-

Sliding Roller Plastic Housing Fits Aluminum Sliding WindowsNewsNov.10,2025

-

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing -

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating -

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges