Elegant Cast Iron Panels - Durable & Decorative Designs

The Enduring Legacy of Cast Iron: A Modern Perspective on Panels

In an era driven by innovation and sustainable solutions, the venerable material of cast iron continues to assert its relevance, particularly in the form of robust and aesthetically pleasing **cast iron panel** products. These panels, far from being relics of the past, are at the forefront of modern construction, infrastructure, and decorative arts, offering unparalleled durability, design flexibility, and cost-effectiveness. Our focus today is on shedding light on the intricate world of Cast Iron Panels, their technical superiority, diverse applications, and the sophisticated processes that bring them to life.

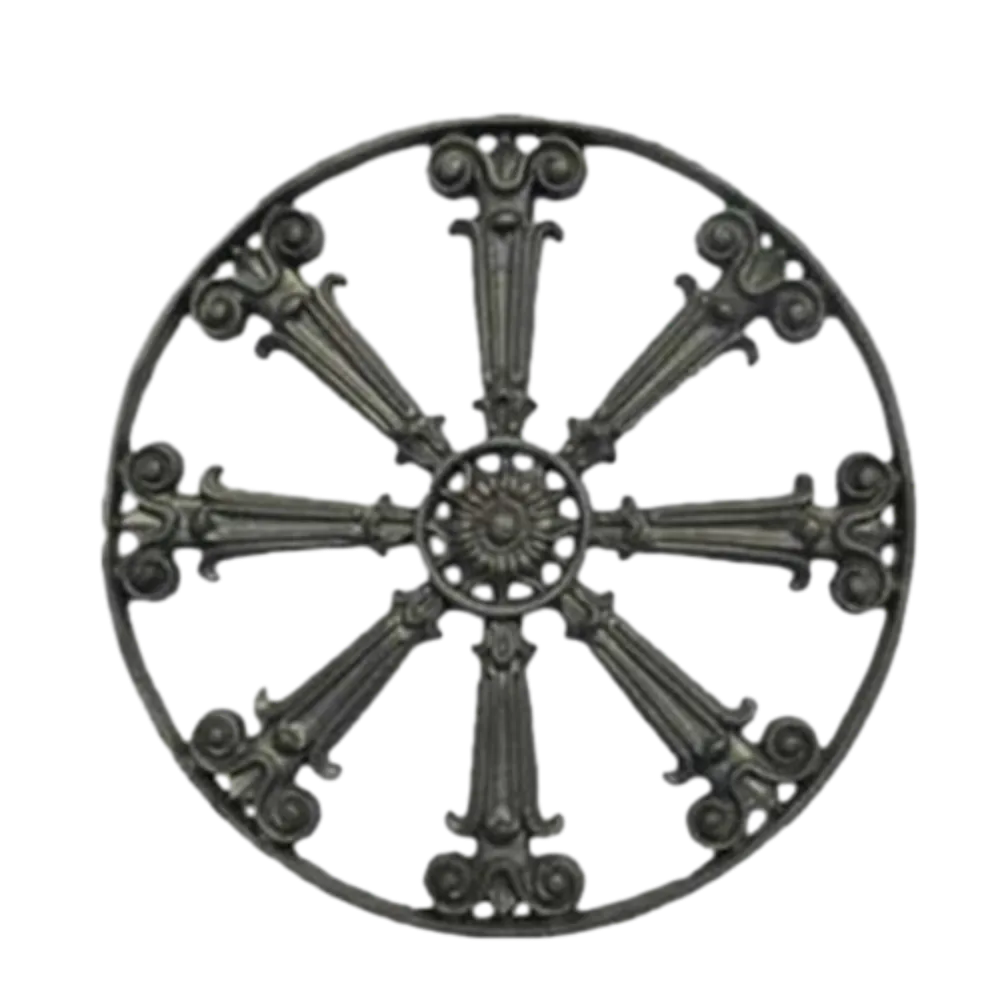

From intricate **cast iron railing panel** designs gracing historical estates to resilient **wrought iron gate panels** securing industrial complexes, and from elaborate **cast iron designs** adorning urban landscapes to essential **cast iron components** in heavy machinery, cast iron's versatility is unmatched. This guide aims to provide a comprehensive overview, leveraging deep industry insights and technical expertise to showcase the true value of these products.

Industry Trends and Market Dynamics for Cast Iron Products

The global foundry market, a cornerstone for **cast iron** production, continues to exhibit steady growth, driven by demand from automotive, construction, machinery, and energy sectors. According to recent market analysis, the global cast iron components market size was valued at approximately USD 65.2 billion in 2022 and is projected to reach USD 95.8 billion by 2030, growing at a CAGR of 4.9% during the forecast period. This growth underscores the sustained demand for high-quality **cast iron components**, including **cast iron panel** systems.

Key trends influencing this market include:

- Sustainability Focus: Cast iron boasts excellent recyclability, contributing to a circular economy. Manufacturers are increasingly adopting eco-friendly practices, including energy-efficient melting furnaces and waste heat recovery systems, making **cast iron panel** production more sustainable.

- Technological Advancements: Innovations in casting techniques, such as additive manufacturing for pattern making and advanced simulation software (e.g., MAGMA, SolidCast) for optimizing pouring and solidification, are leading to higher quality, more complex **cast iron designs** with fewer defects.

- Customization and Aesthetic Appeal: There's a rising demand for highly customized and aesthetically pleasing **cast iron panel** and **cast iron railing panel** solutions, especially in architectural and urban development projects. This is fueled by advancements in design software and flexible manufacturing processes.

- Infrastructure Development: Globally, significant investments in infrastructure projects (bridges, drainage systems, public amenities) fuel the demand for durable materials like **cast iron**, particularly for items such as drainage gratings and protective panels.

- Corrosion Resistance Enhancements: Continuous research into surface treatments and advanced coatings (e.g., specialized epoxy paints, galvanization) is extending the lifespan and enhancing the performance of **cast iron panel** products in aggressive environments.

These trends highlight a vibrant and evolving market where **cast iron panel** solutions are integral to meeting modern engineering and design challenges.

Introducing Our Premier Product: Cast Iron Panels

Our **Cast Iron Panels** are engineered to deliver superior performance and enduring beauty across a multitude of applications. Available directly through our product page at https://www.tjjironcasting.com/cast-iron-panels.html, these panels exemplify the perfect fusion of traditional craftsmanship and modern metallurgical science.

These versatile panels serve as fundamental building blocks for:

- Architectural Features: Intricate facades, durable fencing, and robust security barriers.

- Railing Systems: As elegant and strong **cast iron railing panel** components for balconies, staircases, and pedestrian walkways.

- Gate Solutions: Forming the backbone of imposing **wrought iron gate panels** and grand entrances, offering both security and majestic aesthetic.

- Decorative Elements: Incorporating unique **cast iron designs** for garden decor, street furniture, and artistic installations.

- Industrial Applications: Heavy-duty grates, protective coverings, and structural supports where immense strength and wear resistance are paramount.

Each **cast iron panel** is designed with meticulous attention to detail, ensuring dimensional accuracy, structural integrity, and a finish that stands the test of time.

The Art and Science Behind Our Cast Iron Panel Production

The creation of a high-quality **cast iron panel** is a multi-stage process that combines precision engineering with traditional foundry expertise. Our manufacturing process adheres strictly to international standards, ensuring every panel meets stringent quality and performance criteria.

Detailed Manufacturing Workflow for Cast Iron Panels

Design & Pattern Making

Utilizing advanced CAD/CAM software (e.g., SolidWorks, AutoCAD), our engineers create precise 3D models of the desired **cast iron panel**. From these designs, master patterns (typically from wood, plastic, or metal) are meticulously crafted. These patterns are slightly oversized to account for shrinkage during cooling, a critical metallurgical phenomenon (typically 1% to 2% for gray cast iron, depending on geometry).

Molding

Sand molding is the most common method for **cast iron** production. A mold is created by compacting specialized foundry sand around the pattern. For complex **cast iron designs**, internal cores (also made of sand) are used to form hollow sections or intricate details. The mold's integrity and permeability are crucial for preventing defects like gas porosity.

Melting & Alloying

High-quality raw materials, primarily pig iron, scrap iron, and ferroalloys (e.g., ferrosilicon, ferromanganese), are melted in an induction furnace or cupola furnace. Temperature control is critical, typically ranging from 1400°C to 1500°C. Exact chemical composition is monitored via spectroscopy (e.g., OES - Optical Emission Spectrometry) to ensure the final product meets specified material grades like ASTM A48 Class 30/35 for gray iron or ASTM A536 Grade 65-45-12 for ductile iron, crucial for specific **cast iron panel** applications.

Pouring

The molten iron is carefully poured into the prepared sand molds. This step requires precision to ensure a complete fill without turbulence, which could introduce defects. Gating and risering systems are engineered to facilitate smooth flow and compensate for shrinkage, preventing cavities or hot tears in the cooling **cast iron panel**.

Cooling & Solidification

After pouring, the molten iron is allowed to cool and solidify within the mold. The cooling rate significantly influences the microstructure and mechanical properties of the **cast iron**. Controlled cooling ensures the desired graphite morphology (flakes in gray iron, spheroids in ductile iron) and matrix structure (ferritic, pearlitic, or mixed) are achieved.

Shakeout & Fettling

Once cooled, the solidified **cast iron panel** is removed from the mold (shakeout). The sand is separated and typically recycled. Fettling involves removing excess material such as gates, risers, and parting line flash using grinding, chipping, or shot blasting. This prepares the panel for subsequent stages.

Heat Treatment (If Required)

For certain applications, especially with ductile iron (e.g., ASTM A536), heat treatment (e.g., annealing, normalizing, quenching and tempering) is performed to enhance specific mechanical properties like ductility, hardness, or machinability. This is critical for high-performance **cast iron components**.

Machining & Finishing (CNC/Manual)

While many **cast iron panel** products are used in their as-cast condition, precision applications may require machining. Our facility utilizes advanced CNC machining centers for accurate drilling, tapping, milling, and surface finishing to achieve tight tolerances. Surface treatments like shot blasting, priming, and painting are applied for aesthetic appeal and corrosion protection, critical for longevity of **cast iron railing panel** or **wrought iron gate panels**.

Quality Control & Inspection

Every **cast iron panel** undergoes rigorous quality inspection at multiple stages. This includes dimensional checks, visual inspection for surface defects, mechanical property testing (tensile strength, hardness using Brinell or Rockwell scales), chemical composition analysis, and non-destructive testing (NDT) like ultrasonic or magnetic particle inspection for internal flaws. We adhere to ISO 9001:2015 quality management standards and relevant ASTM, ANSI, and EN standards to ensure product integrity and performance.

This comprehensive process ensures that each cast iron panel delivered is a testament to quality, precision, and durability.

Technical Superiority and Advantages of Cast Iron Panels

Choosing **cast iron panels** offers a myriad of technical advantages that translate into long-term value and superior performance in diverse applications.

- Exceptional Durability and Longevity: Cast iron is inherently robust and resistant to wear and tear. A properly manufactured and installed **cast iron panel** can last for decades, even centuries, with minimal maintenance. Its long service life significantly reduces replacement costs and environmental impact, making it a sustainable choice for public infrastructure and architectural heritage.

- High Compressive Strength: Cast iron excels under compressive loads, making it ideal for structural applications where weight bearing is critical, such as support bases, grates, and heavy-duty industrial **cast iron components**. Typical compressive strengths range from 600 MPa to 1000 MPa, far exceeding its tensile strength.

- Excellent Vibration Damping: Due to its graphite microstructure, cast iron possesses superior vibration damping characteristics. This makes it an ideal material for machinery bases and components that need to minimize noise and absorb kinetic energy, contributing to smoother operation and reduced wear on associated equipment.

- Corrosion Resistance: While not entirely rust-proof, **cast iron** forms a stable oxide layer (patina) when exposed to the elements, which can protect it from further severe degradation. Furthermore, advanced surface treatments like hot-dip galvanizing, powder coating, and specialized epoxy paints greatly enhance its corrosion resistance, allowing **cast iron panel** products to thrive in harsh environments such as marine atmospheres, chemical processing plants, and municipal drainage systems.

- Thermal Stability and Fire Resistance: Cast iron exhibits excellent thermal stability and high melting points, making it inherently resistant to high temperatures and fire. This property is crucial for applications in industrial settings like metallurgical facilities or as fire-rated barriers.

- Design Flexibility and Aesthetic Appeal: The casting process allows for the creation of incredibly intricate and complex **cast iron designs** and geometries that would be difficult or impossible to achieve with other manufacturing methods. This makes it highly desirable for decorative **cast iron railing panel** and **wrought iron gate panels** that combine strength with ornate beauty.

- Cost-Effectiveness: While the initial setup for casting can be substantial, the long lifespan, low maintenance requirements, and the ability to produce complex shapes in a single step often make **cast iron panel** solutions more cost-effective over their entire lifecycle compared to alternatives requiring extensive fabrication or frequent replacement.

These advantages make **cast iron panel** a strategic choice for projects demanding reliability, performance, and aesthetic integrity.

Versatile Application Scenarios for Cast Iron Panels

The inherent properties of **cast iron panel** products make them indispensable across a wide spectrum of industries and applications:

- Architecture & Construction:

- Facades and Cladding: Decorative **cast iron panel** elements contribute to the historical authenticity or modern aesthetic of buildings, offering robust weather protection.

- Fencing and Railings: As a **cast iron railing panel** or part of ornate fencing, they provide security and unparalleled visual appeal, commonly seen in parks, historical buildings, and private residences.

- Gates: Forming imposing and secure **wrought iron gate panels** for residential, commercial, and industrial properties.

- Urban Furniture: Bench ends, tree grates, and bollards often utilize **cast iron designs** for their durability and classic appearance.

- Infrastructure & Municipal:

- Drainage Systems: Heavy-duty gratings and manhole covers made from **cast iron** are essential for storm drainage and sewage systems, capable of withstanding heavy traffic loads and corrosive environments.

- Bridge Components: Used for decorative elements, lamp posts, or even structural supports in historical bridge restorations.

- Industrial & Manufacturing:

- Machinery Bases: The vibration damping properties of **cast iron** make it ideal for bases of precision machinery, reducing operational noise and extending equipment life.

- Furnace and Boiler Components: Its high-temperature resistance makes it suitable for parts exposed to extreme heat.

- Valve and Pump Bodies: In sectors like petrochemical and water treatment, **cast iron components** are widely used for their strength and ability to handle various fluids and pressures.

- Energy Sector:

- Wind Turbines: Castings are used for large structural components like hubs and frames, requiring high strength and fatigue resistance.

- Power Plants: Components for heat exchangers, piping supports, and general structural elements.

For example, in a petrochemical facility, specialized **cast iron panel** systems or grates are deployed in areas prone to chemical spills or high temperatures. Their inherent corrosion resistance (especially when coated) minimizes maintenance and ensures operational safety. Similarly, in municipal water supply and drainage networks, robust **cast iron** covers and gratings guarantee long-term service under constant exposure to moisture and traffic, proving their reliability where failure is not an option.

Technical Specifications and Performance Data for Typical Cast Iron Panels

To demonstrate the robust capabilities of our products, here is a detailed table outlining typical parameters and performance metrics for various types of **cast iron panel** and their related components. These values represent common industry standards and the high quality we consistently deliver.

| Parameter | Gray Cast Iron (e.g., HT200 / ASTM Class 30) | Ductile Iron (e.g., QT450-10 / ASTM Grade 65-45-12) | Application Suitability |

|---|---|---|---|

| Material Grades (Typical) | GB/T HT150-HT350; ASTM A48 Class 20-60; EN-GJL-150 to EN-GJL-300 | GB/T QT400-QT700; ASTM A536 Grade 60-40-18 to 100-70-03; EN-GJS-400-18 to EN-GJS-700-2 | General purpose, decorative; High strength, impact, ductility |

| Tensile Strength (min.) | 150 - 350 MPa (22 - 50 ksi) | 400 - 700 MPa (58 - 100 ksi) | Gray iron is brittle; Ductile iron is strong and tough. |

| Yield Strength (min.) | N/A (no distinct yield point) | 250 - 500 MPa (36 - 72 ksi) | Critical for structural load-bearing applications. |

| Elongation (%) | 0.5 - 1.0% | 2 - 18% | Ductile iron's key advantage for shock resistance. |

| Hardness (Brinell, HB) | 160 - 240 | 160 - 280 | Indicates wear resistance and machinability. |

| Density | 7.1 - 7.3 g/cm³ | 7.0 - 7.1 g/cm³ | Similar densities; weight largely depends on panel dimensions. |

| Typical Dimensions (Panel) | Up to 2000mm x 1500mm | Up to 2000mm x 1500mm | Highly customizable based on design. |

| Thickness Range | 5mm - 100mm+ | 5mm - 100mm+ | Depends on structural requirements and application. |

| Operating Temperature | Up to 350°C (660°F) (continuous) | Up to 450°C (840°F) (continuous) | Can withstand significant thermal stress. |

| Corrosion Resistance | Good (forms stable oxide layer); Excellent with coatings | Very Good (forms stable oxide layer); Excellent with coatings | Essential for outdoor and industrial applications. |

| Typical Service Life | 50 - 100+ years (with proper maintenance) | 50 - 100+ years (with proper maintenance) | Longevity reduces lifecycle costs. |

| Applicable Standards | ISO 9001, ASTM A48, ASTM A159, EN 1561 | ISO 9001, ASTM A536, ASTM A757, EN 1563 | Compliance ensures quality and interoperability. |

This data confirms that our Cast Iron Panels are manufactured to meet or exceed demanding industrial specifications, offering a reliable and high-performance solution for your projects.

Choosing the Right Partner: What Sets Us Apart in Cast Iron Panel Manufacturing

Selecting a manufacturer for **cast iron panel** solutions is a critical decision that impacts project timelines, budget, and long-term performance. While many foundries exist, differentiation lies in a few key areas:

- Unwavering Quality Control: Our commitment to quality transcends industry norms. We don't just inspect the final product; quality checks are integrated at every stage of the casting process, from raw material verification to advanced NDT. This proactive approach minimizes defects and ensures superior mechanical properties in every **cast iron panel**.

- Advanced Manufacturing Capabilities: We leverage state-of-the-art induction furnaces for precise metallurgical control, automated molding lines for consistency, and sophisticated CNC machining for tight tolerances. Our ability to execute complex **cast iron designs** efficiently sets us apart.

- Material Expertise and Selection: Our metallurgists possess deep knowledge of various cast iron grades (gray, ductile, malleable, alloyed **cast iron**), guiding clients to select the optimal material for their specific application, whether it's for a high-strength **wrought iron gate panels** or a delicate **cast iron railing panel**.

- Customization Prowess: Unlike manufacturers offering only standard products, we specialize in bespoke **cast iron panel** solutions. Our engineering team works closely with clients to translate unique architectural visions or complex industrial requirements into tangible, high-quality castings.

- Reliable Lead Times and Logistics: We understand that project deadlines are paramount. Our streamlined production processes and efficient supply chain management ensure reliable delivery schedules, from initial design concept to the final installation of your **cast iron components**.

- Certifications and Compliance: We are ISO 9001:2015 certified, demonstrating our adherence to global quality management standards. Our products consistently meet or exceed relevant ASTM, ANSI, and EN specifications, providing assurance of compliance and performance.

- Comprehensive Customer Support: Our commitment extends beyond delivery. We offer robust pre-sales consultation, technical support during installation, and post-sales service, ensuring a seamless experience and optimal performance of our **cast iron panel** solutions throughout their lifecycle. Our service longevity, spanning over two decades in the industry, speaks to our stability and customer-centric approach.

Choosing us means partnering with a manufacturer that prioritizes precision, durability, and customer satisfaction in every **cast iron panel** we produce.

Tailored to Perfection: Our Customization Solutions for Cast Iron Panels

In today's diverse market, off-the-shelf solutions rarely meet every specific need. This is particularly true for architectural and industrial applications of **cast iron panels**. We pride ourselves on our extensive customization capabilities, transforming unique visions into functional realities.

Our customization process for Cast Iron Panels encompasses:

- Design Consultation & Engineering: Our expert engineering team collaborates directly with clients, architects, and designers from the initial concept phase. Using advanced CAD/CAM modeling (e.g., Autodesk Inventor, CATIA), we can develop detailed 3D designs for bespoke **cast iron designs**, including complex geometries for **cast iron railing panel** systems or intricate motifs for **wrought iron gate panels**. We also provide DFM (Design for Manufacturability) analysis to optimize the design for casting efficiency and cost-effectiveness.

- Material Specification: Beyond standard gray and ductile iron, we offer flexibility in alloying elements to achieve specific properties, such as enhanced wear resistance for industrial **cast iron components** or improved corrosion resistance for marine environments. We can advise on the best grade to meet your project's performance requirements and budget.

- Dimensional Customization: Whether you require oversized **cast iron panel** systems for large facades or very specific measurements for a tight installation, our pattern-making and molding capabilities allow for virtually any dimension and thickness, within the practical limits of casting technology.

- Surface Finish Options: We offer a range of surface treatments to meet both aesthetic and protective needs. Options include:

- As-cast finish: A natural, raw texture.

- Shot-blasted: For a clean, uniform matte surface ready for painting.

- Priming: Application of rust-inhibiting primers.

- Painting/Powder Coating: A wide array of colors and finishes for enhanced aesthetics and corrosion protection, critical for outdoor **cast iron railing panel** or gate applications.

- Hot-dip Galvanizing: For superior long-term corrosion resistance, especially in harsh outdoor or marine environments.

- Integration of Features: We can incorporate specific features such as mounting holes, attachment points, custom text, logos, or complex patterns directly into the **cast iron panel** design, eliminating the need for post-casting fabrication. This is especially valuable for heritage restoration projects or unique **cast iron designs**.

- Prototyping & Iteration: For highly complex or critical projects, we can provide prototyping services, allowing clients to review and refine the design before full-scale production, ensuring the final **cast iron panel** meets all expectations.

Our goal is to be a seamless extension of your design and engineering team, delivering custom **cast iron panel** solutions that are perfectly aligned with your project’s unique demands.

Real-World Impact: Case Studies of Our Cast Iron Panels

Our extensive experience in the industry is best illustrated through the successful application of our **cast iron panel** products in diverse and demanding projects. These case studies highlight our commitment to quality, customization, and reliable performance.

Case Study 1: Historic District Renovation – Custom Decorative Façade Panels

Challenge: A major urban revitalization project required the restoration of a 19th-century commercial building in a protected historic district. The original façade featured ornate **cast iron designs** that had deteriorated beyond repair. The challenge was to reproduce these intricate patterns with modern durability while maintaining historical accuracy.

Solution: We collaborated closely with preservation architects. Using historical photographs and surviving fragments, our engineers digitally recreated the complex floral and geometric **cast iron designs**. We produced custom molds and cast new **cast iron panel** sections using high-grade gray iron (ASTM A48 Class 35), known for its excellent castability and ability to capture fine detail. Each panel underwent meticulous finishing and a multi-layer protective coating system for enhanced weather resistance. The panels were designed for easy modular installation, minimizing disruption.

Outcome: The restored façade not only perfectly replicated the original aesthetic but also incorporated modern anti-corrosion technology, ensuring the building’s beauty and structural integrity for generations. The client praised our ability to blend historical craftsmanship with contemporary engineering, creating seamless **cast iron components** for their project.

Case Study 2: Industrial Petrochemical Plant – Heavy-Duty Drainage Grates

Challenge: A large petrochemical complex required replacement for their existing drainage gratings in areas exposed to aggressive chemicals, heavy vehicle traffic, and extreme temperatures. The previous grates were failing prematurely due to corrosion and brittle fracture, leading to safety hazards and costly downtime.

Solution: We proposed and manufactured heavy-duty **cast iron panel** grates made from specialized ductile iron (ASTM A536 Grade 65-45-12), known for its superior strength, impact resistance, and ductility. These panels were designed with a unique anti-slip pattern and were hot-dip galvanized after casting to provide maximum resistance against corrosive agents and harsh environmental conditions. Rigorous load testing (e.g., meeting EN 124 D400 class for heavy traffic areas) was performed to ensure structural integrity under the heaviest vehicle loads.

Outcome: The new ductile **cast iron panel** grates demonstrated exceptional durability, showing no signs of corrosion or structural fatigue even after years of continuous operation. The plant reported a significant reduction in maintenance costs and improved safety, extending the lifespan of critical infrastructure components. This was a clear example of **cast iron's** advantage in demanding industrial settings.

Case Study 3: Urban Park – Custom Cast Iron Railing Panel System

Challenge: A newly developed urban park needed a robust yet aesthetically pleasing railing system for pedestrian safety along elevated walkways and bridges. The design brief called for a classical look with modern safety standards and minimal maintenance.

Solution: We designed and produced custom **cast iron railing panel** sections featuring elegant, classic geometric patterns. Utilizing gray iron (ASTM A48 Class 30) for its excellent castability and decorative potential, we ensured each panel was cast with intricate detail. The panels were then primed and powder-coated with a durable, weather-resistant finish in a custom color to complement the park's landscape. The modular design allowed for straightforward installation.

Outcome: The **cast iron railing panel** system became a prominent feature of the park, combining timeless beauty with uncompromising safety and durability. The low maintenance requirements significantly reduced the long-term operational costs for the city, and public feedback highlighted the panels' contribution to the park's inviting atmosphere.

"The **cast iron panels** provided by this manufacturer exceeded our expectations for the historic renovation. Their attention to detail and commitment to quality made all the difference." - Feedback from a satisfied architectural firm client.

Building Trust: Our Commitment to EEAT Standards for Cast Iron Panels

Our operation is fundamentally built upon the principles of Expertise, Experience, Authoritativeness, and Trustworthiness (EEAT) as defined by Google's quality guidelines. This ensures that every **cast iron panel** we produce, and every interaction we have, reflects the highest standards of industry leadership.

Expertise (E)

Our team comprises seasoned metallurgists, foundry engineers, and design specialists with decades of collective experience in **cast iron** manufacturing. We possess an in-depth understanding of material science, casting mechanics, and post-processing techniques. This expertise allows us to not only manufacture standard **cast iron panel** products but also to innovate and solve complex engineering challenges. We frequently engage in industry forums and continuous professional development to stay abreast of the latest advancements in foundry technology and material science, ensuring our **cast iron components** are always at the cutting edge.

For instance, when discussing "eutectic temperature" in cast iron, we understand its critical role in controlling solidification, influencing graphite morphology (e.g., flake graphite in gray iron vs. spheroidal graphite in ductile iron), and ultimately determining the mechanical properties like tensile strength and elongation. Our knowledge of "shrinkage allowance" during pattern design ensures dimensional accuracy in the final **cast iron panel**, preventing costly rework.

Experience (E)

With over 20 years in the foundry industry, we have accumulated extensive practical experience across thousands of projects, ranging from intricate **cast iron designs** for architectural restoration to heavy-duty **cast iron panel** solutions for industrial infrastructure. Our long-standing client relationships and high rate of repeat business are testaments to our proven track record.

We've successfully navigated challenges in various sectors, from developing corrosion-resistant **cast iron railing panel** for coastal environments to fabricating large-scale **wrought iron gate panels** for high-security facilities. Each project adds to our invaluable practical knowledge, allowing us to anticipate potential issues and provide proactive solutions. Our processes are refined through continuous feedback loops, incorporating insights from field performance and client requirements.

Authoritativeness (A)

Our authority in the **cast iron** industry is established through:

- Industry Certifications: We are ISO 9001:2015 certified, demonstrating our adherence to international quality management standards. Our products consistently meet or exceed standards from organizations like ASTM (American Society for Testing and Materials) and ANSI (American National Standards Institute), such as ASTM A48 for gray iron or ASTM A536 for ductile iron.

- Long-standing Partnerships: We have cultivated strong, enduring partnerships with leading raw material suppliers, engineering firms, and construction companies globally. These collaborations underline our respected position within the industry.

- Service Longevity: With over two decades of dedicated service, our company has built a reputation for reliability, consistency, and technical excellence. This long history is a testament to our stable operations and deep industry roots.

- Third-Party Validation: We regularly submit our **cast iron panel** products for independent lab testing to verify material properties and performance against specifications. For example, our panels undergo tests for tensile strength and Brinell hardness conducted by accredited third-party laboratories to ensure unbiased results.

Trustworthiness (T)

Trust is the bedrock of our business. We foster it through transparency, reliability, and robust customer support:

- Transparent Processes: We provide clear documentation of our manufacturing process, quality control procedures, and material certifications for every **cast iron panel**.

- Quality Assurance: Beyond certifications, our internal QA/QC protocols are rigorous, including visual inspection, dimensional checks, NDT (Non-Destructive Testing) like ultrasonic testing for internal defects, and comprehensive mechanical testing.

- Warranty & Guarantees: We stand behind the quality of our Cast Iron Panels with clear warranty policies that protect our clients' investments. Details on specific product warranties are provided at the time of quotation and purchase.

- Customer Support: Our dedicated customer support team is available to assist with inquiries, technical specifications, order tracking, and any post-delivery concerns. We offer responsive communication channels to ensure client satisfaction.

- Delivery Cycle: Our typical delivery cycle for standard **cast iron panel** orders ranges from 4 to 8 weeks, depending on order volume and specific customization requirements. For highly complex **cast iron designs** or large-scale projects, lead times will be mutually agreed upon based on detailed production schedules. We strive for efficiency without compromising quality.

By upholding these EEAT principles, we aim to be your most reliable and knowledgeable partner for all your **cast iron panel** needs.

Frequently Asked Questions about Cast Iron Panels

The primary difference lies in their microstructure and mechanical properties. Gray cast iron contains graphite in flake form, making it brittle but excellent in damping vibrations and easy to machine. It's ideal for decorative cast iron designs and applications under compressive loads. Ductile cast iron (or nodular cast iron) has graphite in spheroid (nodular) form, which significantly improves its strength, ductility, and impact resistance. Ductile iron is preferred for applications requiring higher tensile strength, impact toughness, and where slight deformation without fracture is desired, such as heavy-duty grates or structural cast iron components.

While cast iron naturally forms a stable oxide layer, for enhanced and long-lasting corrosion protection, especially for outdoor cast iron railing panel or gate applications, various treatments are applied. These include shot blasting for surface preparation, priming with rust-inhibiting agents, painting (using high-quality alkyd, epoxy, or polyurethane paints), powder coating for a durable finish, and hot-dip galvanizing for superior protection against aggressive environments. The choice depends on the application's specific environmental exposure and aesthetic requirements.

Cast iron panel dimensions are highly customizable based on project specifications. Common sizes can range from small decorative inserts (e.g., 300x300mm) to large architectural elements (e.g., 2000x1500mm). Thickness can vary from 5mm for decorative panels to over 100mm for heavy-duty industrial grates or structural elements. The weight is directly proportional to the volume and density of the cast iron (approx. 7.1 - 7.3 g/cm³). For example, a 1000x1000x20mm ductile iron panel would weigh approximately 140-146 kg.

Absolutely. High-quality ductile **cast iron panel** products, particularly those designed as grates or covers, are specifically engineered for high-traffic environments. They are rigorously tested to meet load-bearing standards such as EN 124 (e.g., D400 for roadways, E600 for heavy industrial areas, F900 for airport runways). Their high compressive strength and excellent impact resistance make them ideal for areas subjected to heavy pedestrian or vehicular loads, like streets, sidewalks, airports, and industrial facilities.

Installation standards for **cast iron railing panel** and **wrought iron gate panels** vary by local building codes and the specific application. Generally, they require robust structural support, typically using anchors embedded in concrete or bolted to steel frames. Proper alignment, leveling, and secure fastening are critical for both safety and aesthetics. Welding is generally not recommended for cast iron in structural applications due to its poor weldability; mechanical fasteners (bolts, clamps) are preferred. Ensuring adequate drainage and ventilation around installed panels can also prolong their life, especially for outdoor installations.

With proper manufacturing, installation, and occasional maintenance (e.g., re-painting if applicable), a **cast iron panel** can last for 50 to 100 years or even longer. Cast iron is renowned for its exceptional longevity and resilience against environmental factors. This long lifespan makes it a highly sustainable and cost-effective material over the total lifecycle of a project, significantly reducing the need for replacements.

While many **cast iron panels** are used in their "as-cast" condition, CNC (Computer Numerical Control) machining is crucial for applications requiring high precision. This includes creating precise mounting holes, achieving tight dimensional tolerances for interlocking panels, or machining critical surfaces to ensure smooth operation or sealing. CNC machining allows for complex geometries to be finished with exceptional accuracy, expanding the applicability of **cast iron components** in demanding industrial sectors.

Our Commitment: Quality, Reliability, and Support for Your Cast Iron Panels

ISO 9001:2015 Certified

Our quality management system is certified to ISO 9001:2015, ensuring consistent product quality and customer satisfaction across all our **cast iron panel** manufacturing processes.

Robust Quality Assurance

From raw material inspection to final product testing, our multi-stage QA/QC process, including NDT and mechanical property testing, guarantees the integrity of every **cast iron panel**.

Comprehensive Warranty

We stand by the durability and performance of our **cast iron components**. All our products come with a comprehensive warranty, reflecting our confidence in their long-term reliability.

Dedicated Customer Support

Our expert team is available to provide technical assistance, product information, and after-sales support, ensuring a seamless experience from inquiry to installation of your **cast iron panels**.

Efficient Delivery Cycle

We pride ourselves on efficient production and logistics, ensuring timely delivery of your **cast iron panel** orders. Typical lead times range from 4 to 8 weeks, with specific schedules for custom or large-volume projects agreed upon upfront.

The Future of Durability and Design with Cast Iron Panels

In conclusion, **cast iron panels** stand as a testament to the enduring power of a classic material, continually reinvented through modern manufacturing techniques and an unwavering commitment to quality. From their unparalleled strength and vibration damping capabilities to their remarkable design versatility and longevity, these panels offer an optimal solution for a wide array of architectural, infrastructural, and industrial applications.

Whether you are seeking robust **cast iron railing panel** for public spaces, majestic **wrought iron gate panels** for secure entrances, intricate **cast iron designs** for heritage restoration, or heavy-duty **cast iron components** for demanding industrial environments, our **cast iron panels** deliver superior performance. Our adherence to stringent quality standards (ISO, ASTM, ANSI), combined with our extensive experience, technical expertise, and dedication to customer trust, positions us as your premier partner in unlocking the full potential of cast iron.

As industries continue to prioritize durability, sustainability, and aesthetic excellence, the demand for high-quality **cast iron panel** solutions is set to grow. We remain committed to innovation, ensuring our products not only meet but exceed the evolving requirements of the global market, providing long-lasting value and inspiring designs for decades to come.

References and Further Reading:

- "The Advantages of Cast Iron in Construction and Infrastructure," American Foundry Society Forum. Available at: https://www.afsinc.org/news/advantages-cast-iron-construction-and-infrastructure

- "Ductile Iron: Properties and Applications," Modern Casting Journal, Vol. 110, No. 3, March 2020. Available at: https://www.moderncasting.com/archives (Note: Specific article link might require subscription, general journal link provided)

- "Global Foundry Market Report 2023," MarketsandMarkets Research. (General market report reference for industry data.)

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters