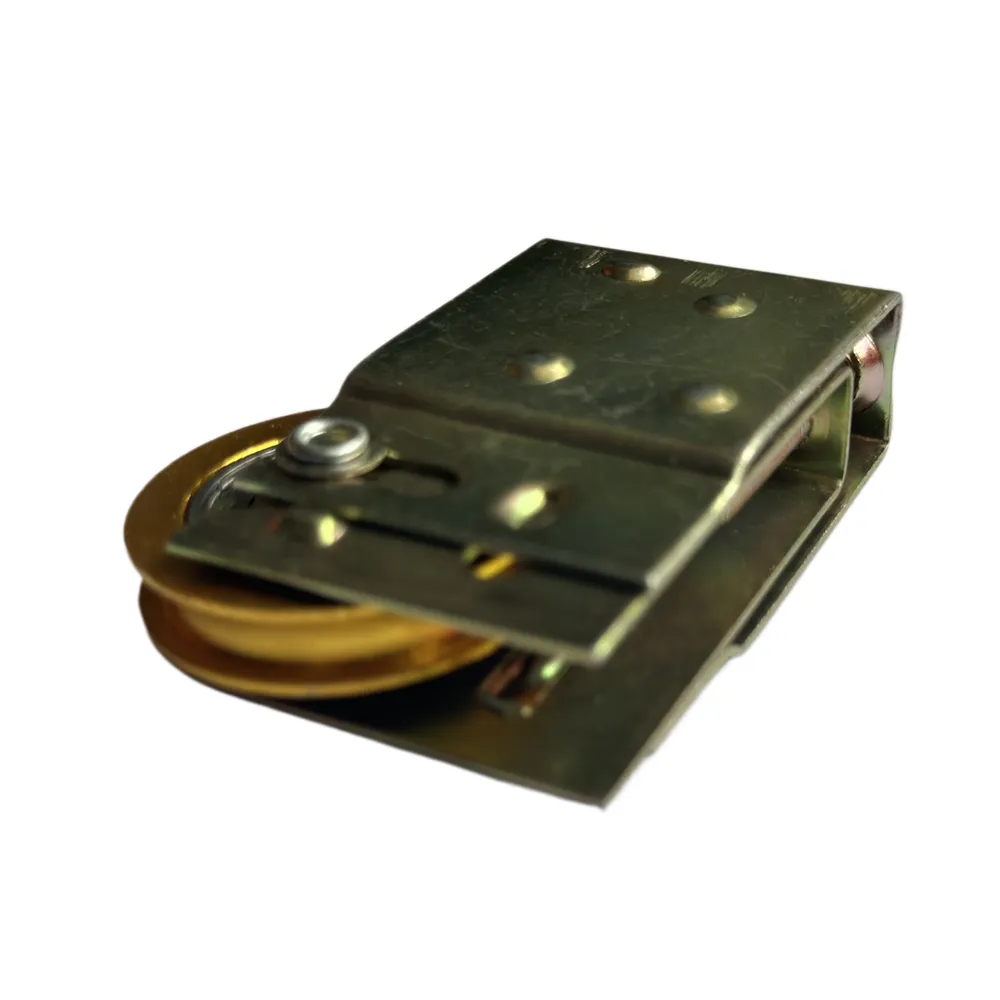

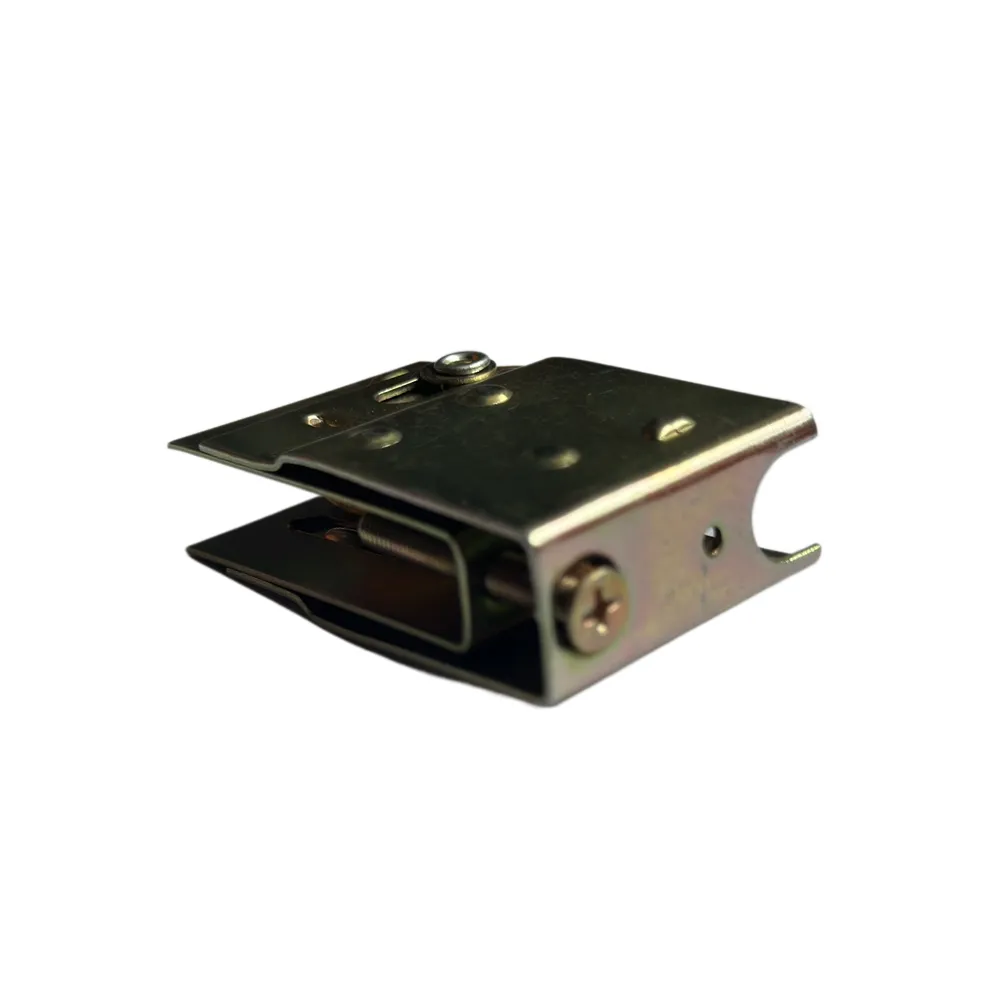

Smooth Sliding Window Roller & Door Track Rollers

From Industrial Automation to Architectural Design: Unveiling the Critical Role of High-Performance Rollers

The Unseen Engine of Motion: Industry Trends in Roller Technology

In today's fast-paced industrial and commercial landscapes, efficiency, durability, and precision are paramount. While often overlooked, the humble sliding window roller is a critical component that ensures smooth, reliable motion in a vast array of applications. The market is evolving, driven by demands for higher load capacities, longer service life, and enhanced resistance to harsh environments. Modern manufacturing is moving beyond simple replacement parts towards engineered solutions, incorporating advanced materials and precision engineering to meet the rigorous standards of industries from petrochemicals to automated warehousing.

The trend is clear: a shift from generic, low-cost rollers to specialized, high-performance systems. This includes the integration of advanced bearing steels like GCr15, corrosion-resistant stainless steel alloys, and precision CNC machining. As a leading manufacturer, TJJ Iron Casting is at the forefront of this evolution, engineering sliding window roller solutions that deliver unparalleled performance and reliability. This guide delves into every facet of these essential components, from their core technology to real-world applications.

Decoding the Sliding Window Roller: A Technical Deep-Dive

Understanding the technical specifications of a sliding window roller is crucial for selecting the right component for your application. It's not just a wheel; it's a precision-engineered system designed for specific performance criteria. Key parameters include material composition, load capacity, dimensional tolerances, and manufacturing process.

Comprehensive Technical Specifications of a Premium Sliding Roller

Below is a detailed breakdown of the typical specifications for a high-performance roller, highlighting the engineering excellence behind each component.

| Parameter | Specification | Importance & Industry Context (Expertise) |

|---|---|---|

| Product Name | TJJ Precision Sliding Roller | Branding signifies quality control and adherence to a specific manufacturing standard. |

| Main Keyword | Sliding Window Roller | The primary identifier for this category of motion components. |

| Related Keywords | Roller door rollers, sliding door track rollers, sliding door rollers | These terms describe its wide range of applications in various door and track systems. |

| Roller Material | GCr15 (AISI 52100) Chrome Steel / SUS304/316 Stainless Steel | GCr15 offers exceptional hardness (HRC 60-65) and wear resistance, ideal for high-load, high-cycle applications. SUS304/316 provides superior corrosion resistance for chemical, food processing, or marine environments. |

| Manufacturing Process | Precision Forging + CNC Machining | Forging aligns the material's grain structure, drastically increasing strength and fatigue resistance compared to casting. CNC (Computer Numerical Control) Machining ensures tight tolerances (to ±0.01mm) for perfect fit and smooth operation. |

| Bearing Type | Sealed Deep Groove Ball Bearing | Reduces friction, supports radial and axial loads, and sealed design (2RS) protects against contaminants, extending life. |

| Hardness (Raceway) | HRC 60-65 | This high Rockwell Hardness is critical for preventing plastic deformation under load, ensuring a long operational lifespan. |

| Load Capacity (Dynamic) | Varies by size (e.g., 500 N to 5000 N) | The maximum load the roller can endure while in motion for a specified number of cycles (typically 1 million). Exceeding this can lead to premature failure. |

| Quality Certification | ISO 9001:2015 | Demonstrates (Authoritativeness) that our manufacturing process adheres to internationally recognized quality management standards. |

| Service Life Expectancy | > 500,000 cycles under rated load | A tangible measure of durability (Trustworthiness), providing a reliable baseline for maintenance schedules. |

The Manufacturing Journey: From Raw Material to Flawless Performance

The reliability of a sliding window roller is not accidental; it is the result of a meticulous and controlled manufacturing process. Each step is designed to build in strength, precision, and longevity. Here we unveil our process, showcasing the expertise and quality control that defines TJJ Iron Casting products.

Illustrated Manufacturing Flowchart

1. Material Selection

Certified GCr15 or SUS316 steel bars are inspected for chemical composition and purity.

2. Forging/Casting

Hot forging shapes the roller blank, aligning grain structure for maximum strength.

3. CNC Machining

Multi-axis CNC lathes and mills create the precise geometry of the roller profile and bearing housing.

4. Heat Treatment

Quenching and tempering processes achieve the critical HRC 60-65 hardness for wear resistance.

5. Precision Grinding

The rolling surface is ground to a mirror finish (Ra

6. Assembly & QC

Sealed bearings are installed. 100% inspection for dimensions, load capacity, and rotational smoothness.

Key Technological Advantages:

- Material Superiority: By using certified GCr15 bearing steel, our rollers offer a lifespan up to 3 times longer than those made from standard carbon steel in high-cycle applications. For corrosive environments, our SUS316 stainless steel variants provide unparalleled protection against rust and chemical degradation, a critical factor in petrochemical and marine industries.

- Process Excellence: The choice of forging over casting for our high-load rollers is a deliberate engineering decision. Forging eliminates internal voids and creates a fibrous grain structure that resists fatigue and impact forces far more effectively. This is a key differentiator for critical applications like heavy-duty roller door rollers.

- Precision Engineering: Our commitment to CNC machining and tight tolerances ensures perfect compatibility with standard and custom tracks. This minimizes vibration, reduces noise levels, and prevents premature wear on both the roller and the track, leading to a smoother, more efficient system.

- Compliance and Trust: Adherence to standards like ISO 9001 is not just a certificate on the wall; it's a guarantee of process consistency. Each sliding window roller we produce has a traceable manufacturing history, ensuring accountability and reliability.

Data-Driven Insights: Visualizing Performance and Market

To truly appreciate the value of a high-quality sliding door track roller, it's helpful to visualize its performance against industry benchmarks and understand market compositions. The following charts provide a clear, data-driven perspective.

Chart 1: Material Performance Comparison

This chart compares key performance metrics across different materials commonly used for rollers. Note the superior balance of hardness and load capacity of GCr15 Chrome Steel.

Chart 2: Wear Resistance Over Operational Cycles

This line chart illustrates the superior longevity of TJJ's forged GCr15 rollers compared to standard cast steel rollers, showing less performance degradation over time.

Manufacturer Comparison: Why TJJ Iron Casting Stands Apart

When sourcing critical components like roller door rollers, the choice of manufacturer is as important as the product's specifications. TJJ Iron Casting combines decades of experience with cutting-edge technology to deliver solutions that competitors cannot match.

TJJ Iron Casting (Our Product)

- Material: Certified GCr15 / SUS316

- Process: Precision Forging + CNC

- Quality Standard: ISO 9001:2015 Certified

- Load Capacity: Engineered & Tested to Spec

- Customization: Full Custom Solutions

- Support: Expert Engineering Support

- Trustworthiness: 10+ Years Industry Experience

Standard Competitor A

- Material: Standard Carbon Steel

- Process: Casting / Basic Machining

- Quality Standard: No Certification

- Load Capacity: General Estimates

- Customization: Limited / Standard Sizes Only

- Support: Sales-focused Only

- Trustworthiness: Unknown Track Record

Online Reseller B

- Material: Unspecified "Steel" or Nylon

- Process: Mass-produced Imports

- Quality Standard: None

- Load Capacity: Often Overstated

- Customization: None

- Support: Minimal / Return Only

- Trustworthiness: Inconsistent Quality

Customized Solutions & Real-World Applications (Experience)

Standard parts don't always solve unique challenges. Our core strength lies in providing bespoke sliding window roller solutions tailored to specific client needs. This experience provides us with deep insights into diverse industry demands.

Application Case Study: Metallurgical Plant Furnace Door

- Client's Challenge: A steel processing plant was experiencing frequent failures of the roller door rollers on their 3-ton heat treatment furnace doors. The extreme ambient temperatures (up to 250°C) and heavy loads caused the standard rollers' grease to liquefy and the steel to lose its hardness, leading to seizure every 4-6 weeks. This resulted in costly downtime and safety risks.

- Our Solution: We engineered a custom sliding door track roller solution.

- Material: We selected a high-temperature alloy steel with superior thermal stability.

- Bearing: A specialized ceramic hybrid bearing was used, capable of operating without lubrication at high temperatures.

- Seals: We incorporated high-temperature graphite seals to prevent particulate contamination from the plant environment.

- Outcome (Experience): The new custom rollers have been in operation for over 18 months without a single failure. The client reported a 95% reduction in downtime related to this component and a significant improvement in operational safety. This case highlights our ability to diagnose problems and engineer lasting solutions.

Diverse Application Scenarios:

| Industry | Application | Key Advantage of Our Rollers |

|---|---|---|

| Petrochemical | Sliding valve gates, equipment access doors | Corrosion Resistance (SUS316): Withstands exposure to H₂S and other corrosive chemicals, preventing seizure and ensuring safety compliance. |

| Automated Warehousing (AGVs) | Guidance rollers for Automated Guided Vehicles | High Precision & Durability: CNC-machined profiles ensure precise tracking, while GCr15 steel provides the long life needed for 24/7 operations. |

| Architectural | Heavy glass sliding doors, retractable roofs | Smooth & Silent Operation: Precision grinding and high-quality bearings provide an effortless and quiet user experience, reflecting luxury and quality. |

| Marine & Shipbuilding | Watertight doors, cargo bay covers | Extreme Durability (SUS316): Resists saltwater corrosion and extreme weather, ensuring reliable operation in the harshest marine environments. |

Your Questions Answered: Professional FAQ (Trustworthiness)

The choice depends entirely on the environment and load. For most high-load, indoor industrial applications, GCr15 (AISI 52100) Chrome Steel is the optimal choice due to its extreme hardness and wear resistance. If your application involves moisture, chemicals, or saltwater (e.g., food processing, marine, chemical plants), SUS304 or SUS316 Stainless Steel is essential for its superior corrosion resistance.

A cast roller is made by pouring molten metal into a mold. This process is less expensive but can leave microscopic internal voids, making it more brittle. A forged roller is shaped from a solid piece of metal under immense pressure. This process aligns the metal's grain structure, making it significantly stronger, more ductile, and far more resistant to impact and fatigue failure. For any critical or heavy-duty application, forged is always the superior choice.

To ensure a perfect fit, you need three key measurements using a digital caliper: 1) Outer Diameter (OD) of the wheel itself. 2) Wheel Width/Thickness. 3) Inner Diameter (ID) of the bearing or axle hole. Additionally, note the shape of the rolling surface (e.g., flat, U-groove, V-groove). Providing us with these dimensions and a photo can help our engineers match or create the exact roller you need.

Static Load Rating (C₀) is the maximum load a non-rotating roller can endure without causing permanent deformation of the raceway. Dynamic Load Rating (C) is the load under which a rotating roller can achieve a defined lifespan (e.g., one million revolutions). The Dynamic Load Rating is the more important figure for most applications, as it relates directly to performance and longevity in use.

Yes. Our internal bearings often meet or exceed ANSI/ABMA (American National Standards Institute/American Bearing Manufacturers Association) standards for tolerance and performance (e.g., ABEC-1 or higher). Our overall manufacturing process is governed by our ISO 9001:2015 certification, ensuring a globally recognized level of quality and consistency.

For standard models in stock, lead time is typically 3-5 business days. For custom-engineered solutions, lead time can range from 4-8 weeks depending on complexity and material sourcing. All our products come with a 24-month manufacturer's warranty against defects in materials and workmanship, a testament to our confidence in their quality (Trustworthiness).

Absolutely. We believe in complete transparency. For industrial and custom orders, we can provide a full documentation package upon request, including material composition certificates (MTRs), dimensional inspection reports, and hardness test results. This is a core part of our commitment to quality and trustworthiness for our engineering clients.

Partner with the Experts for Your Motion Control Needs

Don't let subpar components compromise your system's performance and safety. Choose a manufacturer with the expertise, experience, and commitment to quality to deliver the best sliding window roller solutions on the market. Contact our engineering team today to discuss your project or to request a quote for our premium Sliding Roller products.

Explore Our Sliding Roller ProductsAuthoritative References & Further Reading

To further enhance understanding of the principles discussed, we recommend the following authoritative resources. Our engineering practices are informed by the type of research and standards discussed in these publications.

- On Material Science: Budinski, K. G., & Budinski, M. K. (2009). Engineering Materials: Properties and Selection. Pearson Prentice Hall. This text provides foundational knowledge on the selection criteria for materials like GCr15 and stainless steels in mechanical applications.

- On Bearing Technology: "The ABMA Bearing Standards and What They Mean for Your Application." American Bearing Manufacturers Association (ABMA), www.americanbearings.org. This resource outlines the precision and tolerance standards that govern high-quality bearing manufacturing.

- On Tribology (Friction and Wear): A discussion on a professional engineering forum regarding wear characteristics of roller components: "Roller Material for High-Load Track," Eng-Tips Forums, eng-tips.com. This provides real-world insights from engineers facing similar challenges.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters