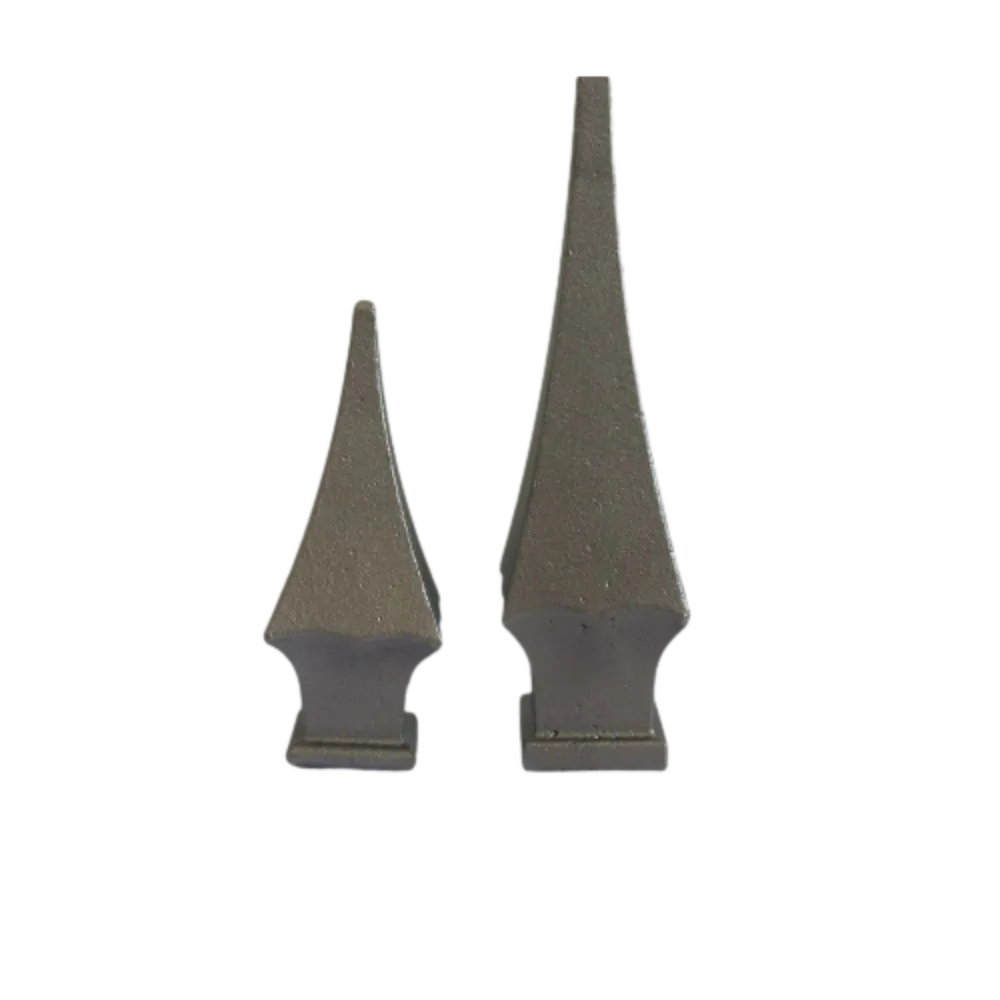

Premium Cast Iron Railheads | Durable Decorative Finials

The Enduring Strength of Cast Iron Railheads in Modern Infrastructure

In the intricate landscape of modern infrastructure and architectural design, the choice of materials plays a pivotal role in ensuring both structural integrity and aesthetic appeal. Among the myriad options, cast iron railheads stand out as a testament to enduring strength, classic elegance, and versatile application. These components, primarily used as decorative and protective elements atop fences, gates, and railings, are experiencing a renewed surge in demand due to their inherent durability, low maintenance requirements, and ability to be intricately customized. The industry is witnessing a trend towards resilient, long-lasting materials that offer both security and a refined finish, aligning perfectly with the properties of traditional yet technologically advanced cast iron products.

Beyond their decorative function, modern applications of cast iron railheads extend into robust security perimeters for commercial, industrial, and public spaces, where longevity and resistance to environmental factors are paramount. The meticulous engineering and advanced casting techniques now employed ensure that these components not only meet but often exceed stringent performance standards. This section will delve into the technical nuances, manufacturing excellence, and diverse applications that solidify cast iron as a material of choice for discerning specifiers and project managers worldwide, emphasizing its role in sustainable and secure construction.

Precision Manufacturing: The Journey of Cast Iron Spear Point Finials

The production of high-quality cast iron railheads, such as the Cast Iron Spear Point Finial, involves a sophisticated multi-stage process that combines traditional metallurgical principles with modern engineering precision. It begins with the selection of premium grade cast iron, typically grey iron (e.g., ASTM A48 Class 30 or EN-GJL-200), known for its excellent castability, vibration damping, and compressive strength. The primary manufacturing technique is sand casting, a highly adaptable and cost-effective method for producing complex shapes with high dimensional accuracy. This process involves creating a mold cavity from sand, into which molten iron, heated to temperatures exceeding 1400°C (2550°F), is poured.

Following solidification, the rough castings are meticulously extracted and undergo a series of finishing operations. This often includes fettling to remove risers and gates, shot blasting to achieve a clean surface finish, and grinding or CNC machining for precise dimensional conformity. For specific designs or enhanced strength, some components may incorporate elements of wrought iron spear production, though the primary structure remains cast. Quality control is rigorous throughout, adhering to international standards such as ISO 9001 for quality management and ANSI/ASTM standards for material properties and dimensional tolerances. Each batch undergoes non-destructive testing, including visual inspection, dimensional checks, and material composition analysis using spectrometry, ensuring optimal performance and an extended service life often exceeding 50 years even in harsh environments.

Image: Typical manufacturing stages for precision cast iron railheads, highlighting quality control points.

Technical Specifications and Performance Metrics

Understanding the technical specifications of cast iron railheads is crucial for ensuring their optimal integration into various projects. These finials are engineered to withstand significant environmental stressors while maintaining their structural integrity and aesthetic appeal. Key parameters include material grade, typically specified by national or international standards like ASTM A48, ranging from Class 20 to Class 40 depending on required tensile strength, or equivalent EN-GJL grades. Surface finishes can range from natural black oxide to various powder coatings or hot-dip galvanization, offering enhanced corrosion resistance, particularly important in coastal or industrial settings.

The dimensional accuracy of cast iron castings is critical, often controlled to within ±0.5mm for critical interfaces and ±1.5mm for overall dimensions, ensuring seamless installation onto existing railing systems. The specific gravity of cast iron, approximately 7.1 g/cm³, contributes to its substantial feel and robust nature. Our products are rigorously tested to ensure compliance with relevant industry standards, demonstrating exceptional resistance to impact, abrasion, and cyclic loading. This meticulous attention to detail and adherence to specified performance metrics guarantee reliability and longevity for all applications, from residential fencing to high-security industrial perimeters.

Typical Specifications for Cast Iron Spear Point Finials

| Parameter | Value/Description |

|---|---|

| Material Grade | Grey Cast Iron (e.g., ASTM A48 Class 30 / EN-GJL-200) |

| Tensile Strength | Min. 200 MPa (29,000 psi) |

| Hardness (Brinell) | 180-240 HB |

| Corrosion Resistance | Excellent (enhanced with galvanization/coating) |

| Dimensional Tolerance | ISO 2768-mK / CT8-CT10 (for casting) |

| Surface Finish Options | Self-color, Primer, Powder Coating, Hot-dip Galvanized |

| Typical Lifespan | 50+ years with proper installation and maintenance |

| Weight Range (per unit) | 0.5 kg - 5 kg (depending on size/design) |

Diverse Applications and Key Advantages

The versatility of cast iron railheads makes them ideal for a broad spectrum of applications across various industries and sectors. In architectural projects, they serve as elegant enhancements for residential and commercial fencing, balconies, and stairway railings, providing a timeless aesthetic that complements both classical and contemporary designs. Within industrial environments, particularly in the petrochemical and power generation sectors, their robust nature and corrosion resistance, especially when paired with advanced coatings, make them suitable for securing perimeters or marking restricted areas. Their inherent mass and strength offer superior deterrent capabilities compared to lighter alternatives.

Beyond traditional fencing, decorative iron elements like these are increasingly employed in public infrastructure projects such as parks, bridges, and municipal buildings, where durability and minimal long-term maintenance are critical for public safety and budget control. The ability of decorative castings to withstand harsh weather, UV radiation, and physical impacts without significant degradation underscores their economic advantage over their lifecycle. For instance, in water supply and drainage systems, where perimeter security is crucial, these railheads provide reliable and enduring barriers that resist environmental degradation, contributing to enhanced operational safety and reducing the need for frequent replacements. Their robust construction ensures they maintain their protective and aesthetic qualities even in challenging industrial or public settings.

Customization Capabilities and Client Success Stories

Recognizing that every project has unique requirements, leading manufacturers of cast iron railheads offer extensive customization options. This includes variations in size, design, and finish to perfectly match architectural specifications or brand aesthetics. Whether requiring a specific spear point profile, a unique base for mounting, or a particular color match for urban landscaping, advanced manufacturing facilities can accommodate bespoke orders with efficiency. Our team leverages state-of-the-art 3D modeling and prototyping to ensure that custom designs meet precise client expectations before full-scale production commences, minimizing lead times and maximizing satisfaction.

We have a proven track record of delivering high-quality cast iron railheads for diverse projects globally. For a major municipal park restoration in North America, our custom-designed spear point finials were chosen to replicate historical designs, providing period authenticity while incorporating modern corrosion-resistant coatings, extending the lifespan significantly. In another instance, for a petrochemical facility's security upgrade, we supplied thousands of galvanized railheads that met stringent blast resistance and security standards, showcasing our capability to handle large-volume, high-specification orders. Our commitment to quality, backed by over two decades of industry experience, ensures that each product delivers on its promise of durability and aesthetic excellence.

Ensuring Trustworthiness: FAQs, Delivery, and Warranty

Transparency and reliability are cornerstone principles when sourcing industrial components. We understand that B2B clients require clear communication regarding product performance, logistics, and after-sales support. All our cast iron railheads are manufactured under strict adherence to ISO 9001 quality management systems, ensuring consistent product quality. Our products have been rigorously tested to comply with international standards, and we can provide relevant certifications, including material test reports (MTRs) and conformity declarations, upon request.

Frequently Asked Questions (FAQs)

-

Q: What is the typical lead time for custom cast iron railheads?

A: Standard orders typically ship within 3-4 weeks. For custom designs or large-volume projects, lead times range from 6-10 weeks, depending on complexity and order size. We provide detailed timelines upon order confirmation. -

Q: How do you ensure corrosion resistance in your products?

A: Our products offer inherent corrosion resistance, but for enhanced protection in harsh environments, we recommend hot-dip galvanization (conforming to ASTM A123) and/or high-quality powder coating. These treatments significantly extend the product's lifespan and appearance. -

Q: What kind of warranty do you offer?

A: We offer a comprehensive 10-year limited warranty against manufacturing defects and material failures under normal use and proper installation. Our robust quality control procedures minimize such occurrences, ensuring your long-term satisfaction. -

Q: Can your decorative castings be integrated with existing metalwork?

A: Yes, our products are designed with standard fitting dimensions where applicable, and our custom fabrication services ensure seamless integration with diverse railing and fence systems, whether new or existing.

Delivery and Support

Our streamlined logistics network ensures efficient and timely global delivery. We work with trusted freight partners to provide competitive shipping options and trackable shipments from our facility to your project site. Our dedicated customer support team is available to assist with technical inquiries, order tracking, and any post-delivery assistance required, ensuring a smooth project execution from start to finish. We prioritize clear communication and proactive support to build lasting partnerships with our clients.

Authoritative References and Industry Insights

- American Society for Testing and Materials (ASTM) International Standards on Cast Iron.

- International Organization for Standardization (ISO) 9001: Quality Management Systems – Requirements.

- ASM Handbook, Volume 15: Casting.

- National Association of Architectural Metal Manufacturers (NAAMM) Metal Finishes Manual.

- Corrosion and Protection of Metals, European Federation of Corrosion Publications.

-

Wrought Iron Components: Timeless Elegance and Structural StrengthNewsJul.28,2025

-

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsNewsJul.28,2025

-

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersNewsJul.28,2025

-

Sliding Rollers: Smooth, Silent, and Built to LastNewsJul.28,2025

-

Cast Iron Stoves: Timeless Heating with Modern EfficiencyNewsJul.28,2025

-

Cast Iron Pipe and Fitting: Durable, Fire-Resistant Solutions for Plumbing and DrainageNewsJul.28,2025

-

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength

Wrought Iron Components: Timeless Elegance and Structural StrengthJul-28-2025Wrought Iron Components: Timeless Elegance and Structural Strength -

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions

Window Hardware Essentials: Rollers, Handles, and Locking SolutionsJul-28-2025Window Hardware Essentials: Rollers, Handles, and Locking Solutions -

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters

Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff CuttersJul-28-2025Small Agricultural Processing Machines: Corn Threshers, Cassava Chippers, Grain Peelers & Chaff Cutters