Are Cast Iron Fence Decorations Durable and Rust-Resistant?

Iron Gate Cast Iron Panels: a field note from the foundry floor

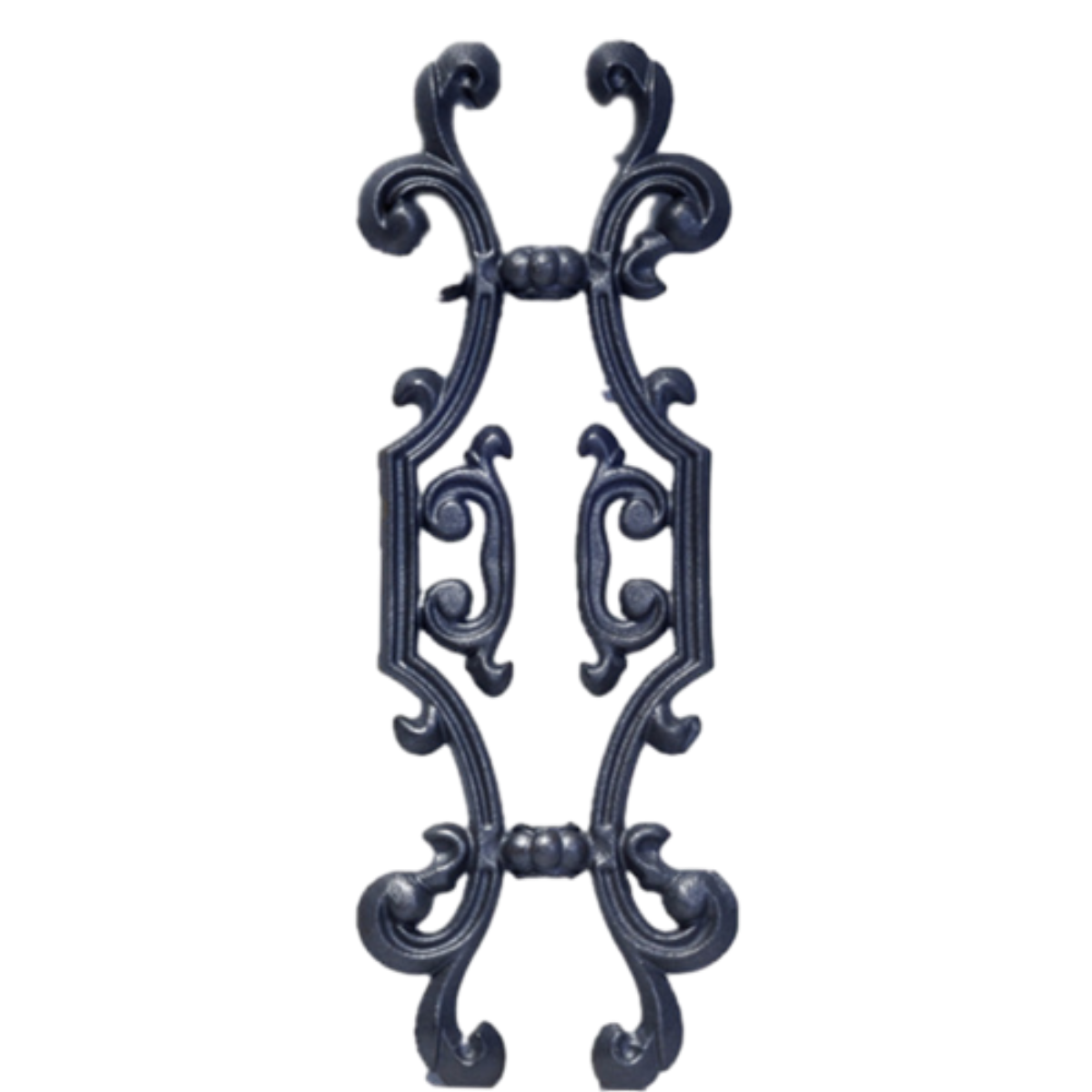

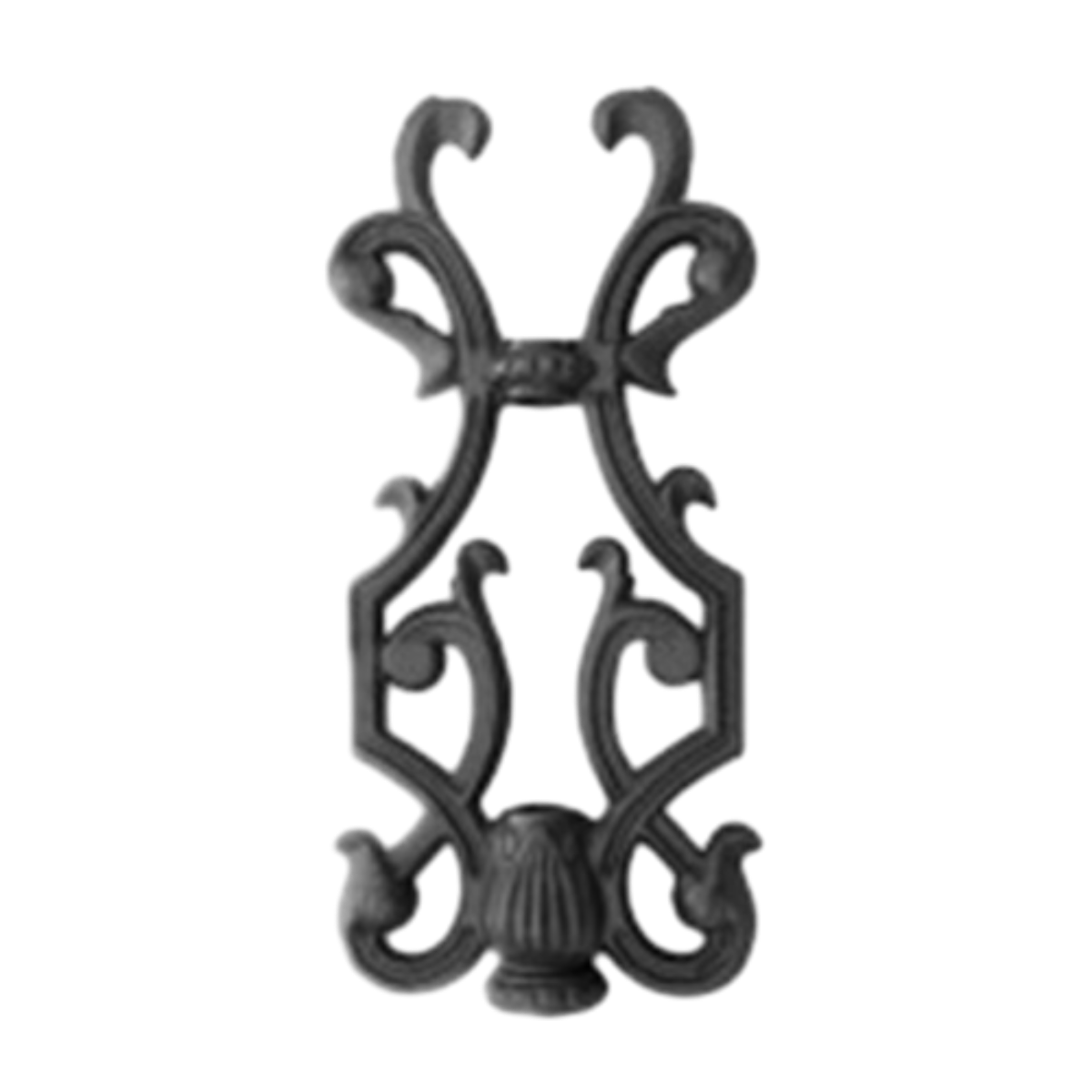

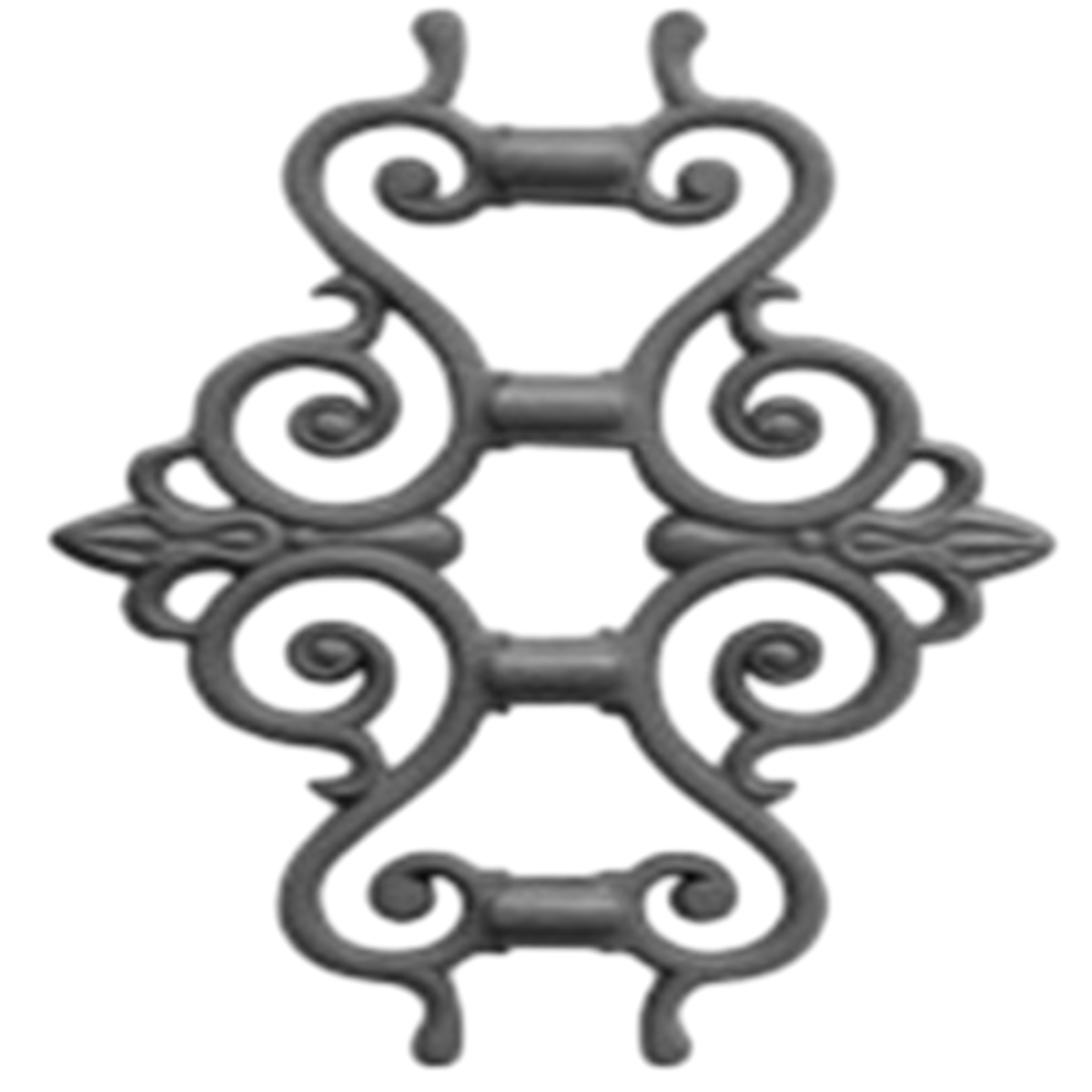

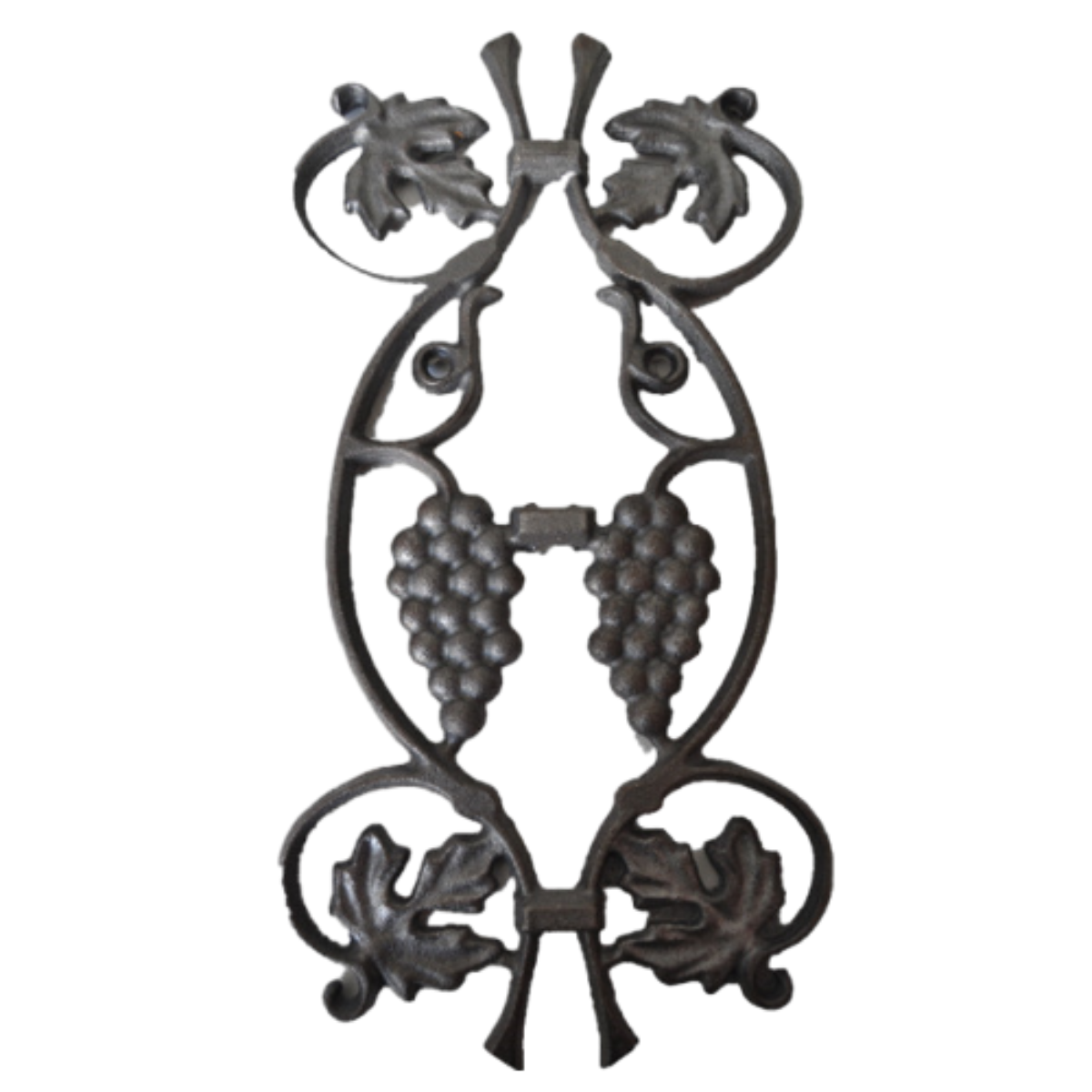

If you’ve ever run your fingers along a century-old gate and felt that cool, solid flourish under your palm—you already understand why cast iron fence decorations are having a quiet, confident comeback. From Shijiazhuang, Hebei Province, China, the Iron Gate Cast Iron Panels range blends old-world craft with modern testing and coatings. I’ve toured similar foundries; the good ones sound like a symphony of sand, steel, and patience.

What’s trending right now

- Modular heritage patterns—classic rosettes with modern fastening points.

- Durable eco-finishes—zinc-rich primers + polyester powder coats (low VOC), typically ISO 12944 C3–C4 duty.

- Security meets style—hidden fasteners, tamper-resistant brackets.

- Customization—CAD-to-casting workflows; RAL color matching is almost expected.

Technical specs at a glance

| Parameter | Typical Value (≈) |

|---|---|

| Base metal | Gray iron EN-GJL-200 (ASTM A48 Class 30); optional ductile EN-GJS-400 |

| Panel size | 300–900 mm modules; thickness 6–12 mm (custom on request) |

| Finish system | SA 2½ blast → zinc-rich epoxy primer → polyester powder topcoat |

| Coating thickness | 80–120 μm total (ISO 2808) |

| Salt spray | ≥ 1,000 h ISO 9227/ASTM B117 (lab), real-world may vary |

| Tolerances | ISO 8062-3 CT8 (typ.), tighter on machined interfaces |

| Service life | 20–30 years with periodic wash and touch-up in C3 environments |

From sketch to street: the process

Materials are selected (chemistry checked via spectrometer), then patterns are cut (often CNC). Sand casting is followed by fettling, shot-blast, and straightening. Critical holes are machined; edges are dressed for a clean arris. Coatings are tested: adhesion (ISO 2409), DFT (ISO 2808), and periodic salt-spray. Honestly, the boring bit—process control—makes the beautiful bit last.

Where they shine

- Residential gates, balconies, garden borders.

- Hospitality entrances and boutique hotels (photo ops matter!).

- Municipal streetscapes, parks, heritage restorations.

- Retail façades that need texture, not just glass and steel.

Why choose these panels

Strength, weight, and that unmistakable shadowline. Many customers say they chose cast iron fence decorations because aluminum felt “too light,” and welded steel lacked the intricacy. Here, motifs are crisp, repeatable, and surprisingly affordable at scale.

Vendor comparison (quick reality check)

| Vendor | Alloy/Finish | Lead Time | Certs | Notes |

|---|---|---|---|---|

| TJJ Iron Casting (Shijiazhuang) | EN-GJL-200 + zinc/PP powder | 30–45 days | ISO 9001; coating test reports | Strong OEM/ODM, flexible MOQ |

| Local fabricator | Often steel, welded, painted | 1–4 weeks | Varies | Fast but fewer patterns; less relief |

| Generic importer | Mixed alloys/finishes | Uncertain | Limited documentation | Lowest cost, variable QC |

Customization and QC

Send DWG/DXF or even a hand sketch; you’ll get CAD renders and a sample casting. Options include ductile iron for impact zones, anti-climb spikes, and RAL colors. QC includes chemical analysis, hardness checks (HB 180–220), and fit-up trials. To be honest, I like seeing the adhesion cross-hatch photos before sign-off.

Case notes (field feedback)

- Coastal B&B in Cornwall: after 18 months, no creep rust at cut edges; owner loved the “weighty feel.”

- Municipal park, Oregon: upgraded to ductile iron near pathways—less chipping from scooters.

- Retail façade in Dubai: matte RAL 9005, low-gloss powder reduced glare under strong sun.

Bottom line: if you want the romance of heritage ironwork with the predictability of modern QA, these cast iron fence decorations hit a sweet spot—honestly, that’s why specifiers keep shortlisting them.

Standards and references

Relevant standards often cited in submittals include ASTM A48 for base metal, ISO 9227 (or ASTM B117) for salt spray, and ISO 12944 for coating system selection by environment. Ask for test reports—good suppliers are happy to share.

- ASTM A48/A48M – Standard Specification for Gray Iron Castings.

- ISO 9227 – Corrosion tests in artificial atmospheres — Salt spray tests.

- ISO 12944 – Paints and varnishes — Corrosion protection of steel structures by protective paint systems.

-

Plough Wheel Cast Iron Material Enhances Load-BearingNewsNov.10,2025

-

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNewsNov.10,2025

-

Rubber Strip Shock Absorption Protects Window EdgesNewsNov.10,2025

-

Aluminum Profiles High Corrosion Resistance Suits Coastal AreasNewsNov.10,2025

-

Window Handle Aluminum Material Ensures Lightweight DurabilityNewsNov.10,2025

-

Sliding Roller Plastic Housing Fits Aluminum Sliding WindowsNewsNov.10,2025

-

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing -

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating -

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges