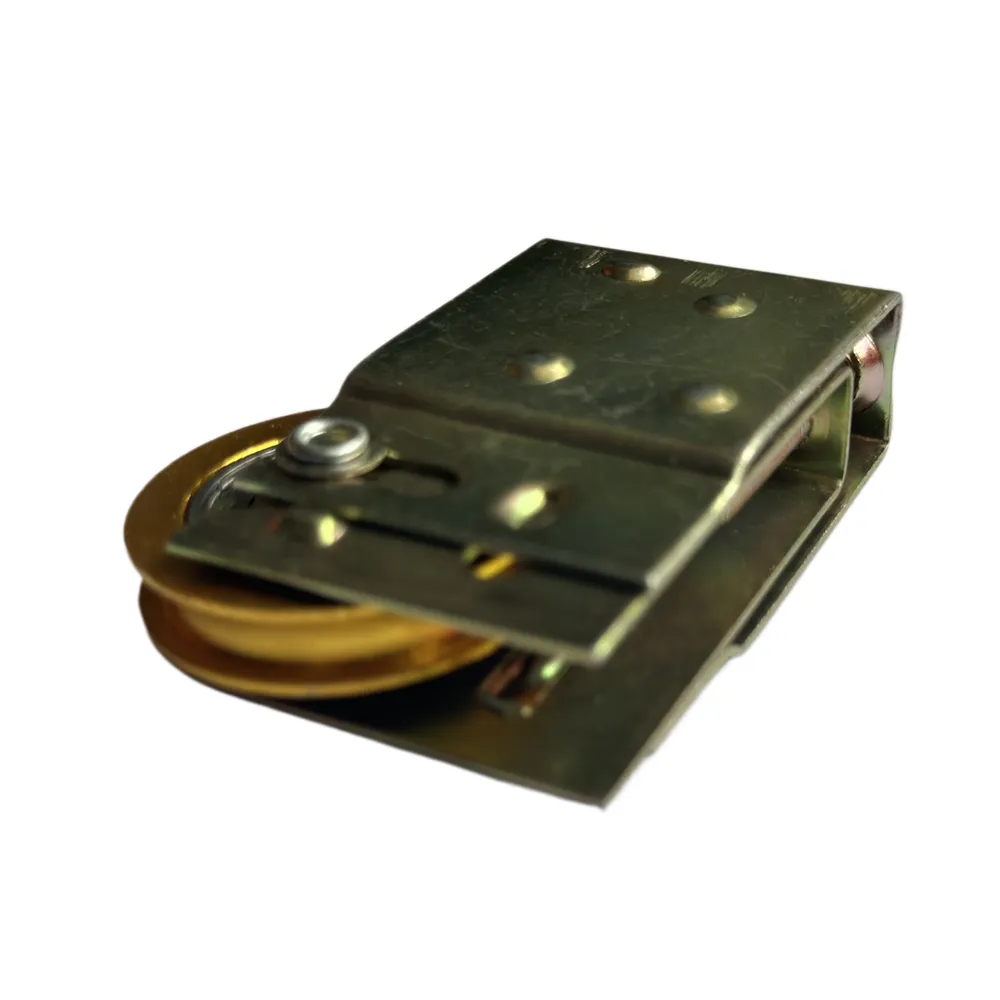

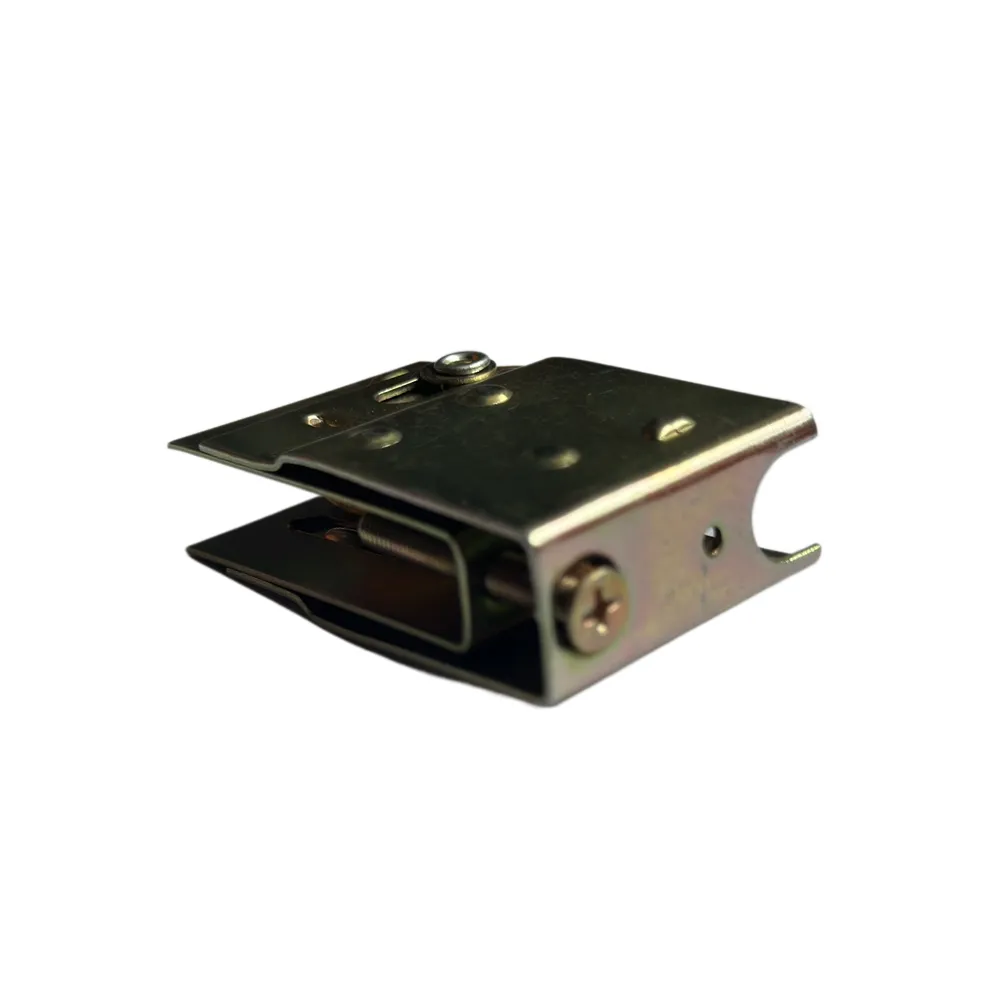

Premium Sliding Window Rollers | Smooth & Quiet Operation

Industry Trends in Advanced Roller Systems

The industrial landscape for roller systems, particularly those designed for demanding applications like heavy-duty sliding mechanisms, is evolving rapidly. Key drivers include the relentless pursuit of enhanced durability, reduced maintenance overhead, and superior operational efficiency across various sectors. Manufacturers and operators are increasingly prioritizing components that offer extended service life and consistent performance under extreme conditions.

Emerging trends point towards the integration of advanced materials, such as specialized alloys and high-performance polymers, to combat corrosion, abrasion, and fatigue. There's a growing demand for precise engineering and manufacturing processes that deliver tighter tolerances and smoother operation, thereby minimizing friction and energy consumption. Furthermore, the adoption of smart manufacturing principles is leading to rollers with integrated monitoring capabilities, allowing for predictive maintenance and optimized operational cycles. This shift impacts components like sliding window roller systems, which are critical in a multitude of industrial and architectural applications, ranging from robust hangar doors to automated factory gates and heavy machinery access panels. The emphasis is on systems that not only facilitate smooth movement but also contribute significantly to the overall structural integrity and energy efficiency of the installations they serve.

Technical Specifications of High-Performance Sliding Rollers

Understanding the intricate technical specifications is paramount for selecting the appropriate sliding window roller for any given industrial application. These specifications dictate the roller's load-bearing capacity, operational lifespan, environmental resilience, and overall performance envelope. Key parameters include material composition, bearing type, surface hardness, corrosion resistance, and operating temperature range.

| Parameter | Specification | Unit/Description |

|---|---|---|

| Material Composition | High-Strength Alloy Steel (e.g., 42CrMo), Stainless Steel (e.g., 304, 316), UHMW-PE (for specific applications) | Material Type |

| Load Capacity (Static) | Up to 500 kN (depending on size and material) | Kilonewtons (kN) |

| Load Capacity (Dynamic) | Up to 250 kN (depending on speed and material) | Kilonewtons (kN) |

| Bearing Type | Precision Sealed Ball Bearings, Tapered Roller Bearings | Type |

| Surface Hardness | HRC 58-62 (for metallic components, heat-treated) | Rockwell C Scale |

| Corrosion Resistance | Excellent (e.g., Stainless Steel, specialized coatings) | Rating/Material |

| Operating Temperature Range | -40°C to +200°C (depending on lubricant and material) | Degrees Celsius |

| Service Life (MTBF) | >100,000 operational cycles or 5 years (under specified conditions) | Cycles/Years |

| Track Compatibility | U-Groove, V-Groove, Flat Track | Profile |

The selection of materials is critical. For instance, in highly corrosive environments, 316 stainless steel offers superior resistance compared to standard carbon steel. For heavy loads and shock resistance, heat-treated alloy steels are often preferred. Bearings are sealed to prevent ingress of contaminants, extending service life, and are typically chosen for their ability to handle both radial and axial loads efficiently. These specifications ensure the sliding window roller performs optimally, minimizing friction and wear across its operational lifespan.

Application Scenarios Across Diverse Industries

The versatility of modern roller systems allows for their deployment in an extensive array of industrial and commercial applications. From facilitating the movement of massive industrial doors to supporting precision machinery, the robust design of the sliding window roller is indispensable. Key application scenarios include:

- Heavy Industrial Doors: Found in warehouses, factories, aircraft hangars, and shipyards, these rollers support substantial door weights, ensuring smooth and reliable operation, even for automated systems.

- Material Handling Systems: Integrated into conveyor systems, automated storage and retrieval systems (AS/RS), and gantry cranes, providing guided movement for heavy loads.

- Automated Gate Systems: Used in commercial and high-security access control gates, where durability and consistent performance are paramount.

- Specialized Machinery: Incorporated into the movement mechanisms of bespoke industrial machinery, offering precise and controlled linear motion.

- Architectural Sliding Panels: For large, heavy architectural elements in commercial buildings requiring smooth, almost silent operation.

In critical infrastructure, such as power generation facilities or petrochemical plants, these rollers must withstand harsh environmental conditions, including high temperatures, chemical exposure, and corrosive atmospheres. Their design often incorporates specialized coatings or materials like stainless steel to ensure longevity and minimize the risk of operational failure. Similarly, in logistics and manufacturing, their reliability contributes directly to streamlined operations and reduced downtime, illustrating their critical role in maintaining operational continuity.

Technical Advantages and Performance Metrics

The technical advantages of a well-engineered sliding window roller translate directly into operational benefits for B2B clients. These advantages extend beyond mere movement to encompass factors like energy efficiency, reduced maintenance, enhanced safety, and prolonged asset life. Key technical advantages include:

- Exceptional Load Bearing: Engineered to support significant static and dynamic loads without deformation or premature wear, ensuring structural integrity for heavy industrial applications.

- Corrosion and Chemical Resistance: Utilization of advanced materials and surface treatments provides superior protection against aggressive chemicals, moisture, and extreme weather, critical for industries like petrochemical and water treatment.

- Low Friction Operation: Precision-machined components and high-quality bearings reduce rolling resistance, leading to energy savings and reduced strain on drive mechanisms.

- Extended Service Life: Robust construction and stringent quality control result in significantly longer operational periods, reducing the frequency and cost of replacements. Typical service life under optimal conditions can exceed 5-7 years, significantly outperforming standard alternatives.

- Minimal Maintenance Requirements: Sealed bearings and durable materials require less frequent lubrication and inspection, contributing to lower operational expenditures (OpEx).

- High Temperature Resilience: Capable of operating effectively in environments with extreme temperature fluctuations, vital for metallurgical facilities and industrial furnaces.

These advantages are quantified through rigorous testing, adhering to international standards such as ISO 9001 for quality management and ANSI standards for specific component dimensions and performance. For example, a high-quality roller door rollers system can demonstrate a 30% reduction in friction coefficients compared to conventional designs, directly translating into tangible energy savings for automated systems. The choice of appropriate materials, such as hardened steel or stainless steel for the roller body, combined with high-precision internal bearings, contributes significantly to these superior performance metrics.

Manufacturing Process Flow of Industrial Sliding Rollers

The manufacturing of high-performance industrial rollers is a complex, multi-stage process demanding precision engineering and rigorous quality control. Our process ensures that each roller meets stringent technical specifications for durability, load capacity, and operational smoothness.

-

Material Selection & Preparation:

- High-grade alloy steels (e.g., 42CrMo4, 34CrNiMo6) or stainless steels (e.g., 304, 316) are selected based on application-specific requirements for strength, wear, and corrosion resistance.

- Raw materials are sourced from certified suppliers, undergoing initial metallurgical inspection to verify composition and structural integrity.

-

Forging or Casting (Dependent on Design):

- For high-stress applications, forging is employed to enhance grain structure, eliminating porosity and improving mechanical properties (tensile strength, fatigue resistance).

- For complex geometries or larger rollers, precision casting might be used, followed by stress relief annealing.

-

Rough Machining:

- Initial turning, boring, and milling operations shape the roller to near-net dimensions, removing excess material.

-

Heat Treatment:

- Processes like hardening, tempering, and carburizing are applied to achieve target surface hardness (e.g., HRC 58-62) and core toughness, significantly extending service life and wear resistance.

- Stress relief is also performed to prevent distortion during subsequent machining.

-

Precision CNC Machining & Grinding:

- Utilizing advanced CNC lathes and grinding machines, critical dimensions, bearing seats, and track profiles (U-groove, V-groove, flat) are machined to micron-level tolerances.

- This ensures optimal fit with sliding door track rollers and minimal friction during operation.

-

Surface Treatment (Optional/Application-Specific):

- For enhanced corrosion protection or wear resistance, surface treatments like chrome plating, nickel plating, nitriding, or specialized polymer coatings (e.g., PTFE) may be applied.

-

Assembly & Bearing Integration:

- High-precision sealed bearings (e.g., deep groove ball bearings, tapered roller bearings) are pressed into place, often pre-lubricated with high-performance grease.

- Seals are installed to protect bearings from dust and moisture.

-

Quality Control & Testing:

- Each sliding door rollers assembly undergoes comprehensive testing, including dimensional checks, hardness testing, surface finish analysis, run-out testing, and load-bearing simulations.

- Testing adheres to international standards such as ISO 492 (Rolling Bearings – Tolerances), ANSI/ABMA standards, and internal quality protocols to ensure a service life exceeding typical industry benchmarks.

-

Final Inspection & Packaging:

- Visual inspection and final performance checks are conducted.

- Products are carefully packaged to prevent damage during transit, often using rust-inhibiting wraps and sturdy crating.

This meticulous process ensures that our sliding rollers deliver superior energy efficiency through reduced friction, exceptional corrosion resistance in challenging environments (e.g., petrochemical and water supply & drainage systems), and unmatched durability for target industries like metallurgy, where high temperatures and heavy loads are standard. Our adherence to ISO 9001 certified manufacturing practices underpins the reliability and long-term performance of every unit.

Vendor Comparison: Key Differentiators in Roller Manufacturing

When sourcing industrial rollers, B2B decision-makers face a critical choice among various vendors. A thorough comparison requires evaluating not just price, but also material quality, manufacturing precision, customization capabilities, and post-sales support. While many suppliers offer standard sliding door rollers, significant distinctions exist in performance and long-term value.

| Feature/Vendor | Our Offering | Typical Competitor A | Typical Competitor B |

|---|---|---|---|

| Material Quality | Certified Alloy Steel (e.g., 42CrMo), 316L SS | Standard Carbon Steel, 304 SS | Proprietary Alloys (often non-standard) |

| Manufacturing Process | Forged & CNC Machined, Heat Treated, Precision Ground | Cast & Machined (lower precision) | CNC Machined from stock bar (less structural integrity) |

| Bearing Quality | SKF/FAG Equivalent, Double-Sealed, Heavy-Duty | Generic Unsealed or Single-Sealed | Mid-range Sealed Bearings |

| Corrosion Resistance | Excellent (316L SS or specialized coatings) | Fair (basic paint or 304 SS) | Good (standard galvanization) |

| Customization Options | Extensive (material, dimensions, track profile, load, coatings) | Limited (standard sizes only) | Moderate (some dimensional changes) |

| Certifications | ISO 9001, Material Certs, Performance Test Reports | Basic QC, no specific external certs | Internal Certs only |

| Warranty | 2-5 Years (Application Dependent) | 1 Year Standard | 1-2 Years |

Our commitment to using premium materials and advanced manufacturing techniques, including precision forging and CNC machining, directly translates to superior product longevity and performance. This is further supported by rigorous adherence to international quality standards like ISO 9001. While initial costs might appear higher than some competitors, the total cost of ownership (TCO) is significantly lower due to reduced maintenance, prolonged service life, and enhanced operational efficiency. We also provide extensive customization options, allowing clients to specify precise requirements for their sliding window roller systems.

Customized Solutions for Unique Industrial Demands

Standard off-the-shelf rollers often fall short of the specific demands posed by complex industrial environments. Recognizing this, we specialize in providing bespoke sliding window roller solutions tailored to exact client specifications. Our engineering team collaborates closely with clients to develop custom rollers that address unique challenges related to load capacity, environmental conditions, operational speed, and integration requirements.

Customization options include:

- Material Specificity: Selection of exotic alloys, specialized stainless steels, or high-performance polymers for extreme temperatures, corrosive agents, or food-grade applications.

- Dimensional Adjustments: Precision engineering to match exact bore sizes, outer diameters, tread profiles (V-groove, U-groove, flat, custom), and overall roller lengths.

- Load and Speed Optimization: Design modifications to bearings and roller body for higher dynamic or static loads, or for operations at elevated speeds without compromising lifespan.

- Integrated Features: Incorporation of specialized features such as lubrication-free designs, integrated sensors for condition monitoring, or specific mounting interfaces.

- Surface Coatings: Application of advanced surface treatments like ceramic coatings, diamond-like carbon (DLC), or specialized anti-corrosion paints for enhanced wear and environmental resistance.

This bespoke approach ensures that clients receive a product perfectly suited to their operational needs, maximizing efficiency and minimizing potential failure points. Our extensive experience and in-house engineering capabilities allow us to prototype, test, and manufacture custom solutions efficiently, significantly reducing lead times for specialized orders.

Application Case Studies

Our sliding rollers have been deployed in numerous challenging industrial scenarios, demonstrating their superior performance and reliability.

Case Study 1: Petrochemical Plant - Heavy Blast Door Rollers

- Challenge: A major petrochemical facility required extremely durable and corrosion-resistant rollers for their heavy blast doors (each weighing 15 tons) in a highly corrosive atmosphere with intermittent exposure to acidic vapors. Existing rollers failed within 18 months due to severe corrosion and bearing fatigue.

- Solution: We designed and supplied custom sliding window roller assemblies made from marine-grade 316L stainless steel, integrated with fully sealed ceramic bearings for superior chemical resistance and zero maintenance. The rollers featured a specialized composite polymer outer shell to prevent sparking.

- Result: The new rollers have been in continuous operation for over 6 years without a single failure or signs of corrosion, far exceeding the client's expectations and significantly reducing maintenance costs and safety risks.

Case Study 2: Metallurgy Industry - Furnace Access Gate Rollers

- Challenge: A metallurgical plant needed rollers for heavy furnace access gates, exposed to extreme temperatures (>150°C continuous, up to 250°C intermittent) and heavy abrasive dust. Standard rollers seized frequently due to lubricant degradation and dust ingress.

- Solution: We provided high-temperature alloy steel rollers, heat-treated for enhanced hardness and fitted with specialized high-temperature graphite bearings. The roller design included a multi-labyrinth seal system to effectively exclude abrasive particles.

- Result: The client reported a 75% reduction in gate maintenance frequency and a 40% improvement in gate opening/closing times due to smoother operation. The rollers have sustained operations for over 4 years in these harsh conditions.

Frequently Asked Questions (FAQ)

Q1: What is the typical lead time for custom sliding window roller orders?

A1: For standard configurations, lead time is typically 4-6 weeks from order confirmation. For highly customized solutions, this can range from 8-12 weeks, depending on material sourcing and complexity. We work closely with clients to meet urgent requirements where feasible.

Q2: What is your warranty policy for industrial rollers?

A2: We offer a comprehensive warranty ranging from 2 to 5 years, depending on the product series and application. This covers manufacturing defects and performance under specified operational conditions. Detailed warranty terms are provided with each quotation.

Q3: How do you ensure the quality and authenticity of materials?

A3: All raw materials are sourced from reputable, certified suppliers and undergo stringent incoming inspection, including material chemical analysis and mechanical property testing. We provide material certifications (e.g., MTCs) upon request to verify authenticity and adherence to standards like ASTM or EN.

Q4: Do you offer technical support for installation and maintenance?

A4: Yes, our technical support team is available to assist with installation guidance, maintenance best practices, and troubleshooting. We can also arrange on-site support or training programs for complex projects upon agreement.

Ordering, Fulfillment & Customer Support

We are committed to a seamless experience from inquiry to post-sales support. Our streamlined process ensures efficient order fulfillment and reliable product delivery.

Lead Time & Fulfillment

Our standard lead times for manufacturing and delivery typically range from 4 to 12 weeks, depending on the complexity of the sliding window roller, material availability, and order volume. For urgent requirements, expedited production and shipping options can be discussed. We utilize a robust supply chain management system to ensure timely procurement and maintain open communication with our clients regarding production status and delivery schedules.

Warranty Commitments

Every industrial roller we produce is backed by a comprehensive warranty, affirming our confidence in our engineering and manufacturing quality. Standard warranties range from 2 to 5 years against defects in material and workmanship under normal operating conditions. Extended warranty options and specific service level agreements (SLAs) are available for critical applications, providing our clients with peace of mind and assurance of long-term reliability.

Dedicated Customer Support

Our commitment extends beyond product delivery. We provide dedicated technical support throughout the product lifecycle, from initial consultation and design assistance to installation guidance and ongoing maintenance advice. Our team of experienced engineers is readily available to address any inquiries, provide troubleshooting assistance, and ensure optimal performance of our rollers in your operations.

References

- International Organization for Standardization. ISO 9001:2015 - Quality management systems – Requirements.

- American National Standards Institute (ANSI) / American Bearing Manufacturers Association (ABMA) Standards.

- ASM International. (2001). ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys.

- Engineered Materials Handbook, Desk Edition. (1995). ASM International.

- SKF. (2007). SKF General Catalogue.

-

Plough Wheel Cast Iron Material Enhances Load-BearingNewsNov.10,2025

-

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNewsNov.10,2025

-

Rubber Strip Shock Absorption Protects Window EdgesNewsNov.10,2025

-

Aluminum Profiles High Corrosion Resistance Suits Coastal AreasNewsNov.10,2025

-

Window Handle Aluminum Material Ensures Lightweight DurabilityNewsNov.10,2025

-

Sliding Roller Plastic Housing Fits Aluminum Sliding WindowsNewsNov.10,2025

-

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing -

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating -

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges