Aluminum Profiles: Versatile Solutions for Modern Construction and Design

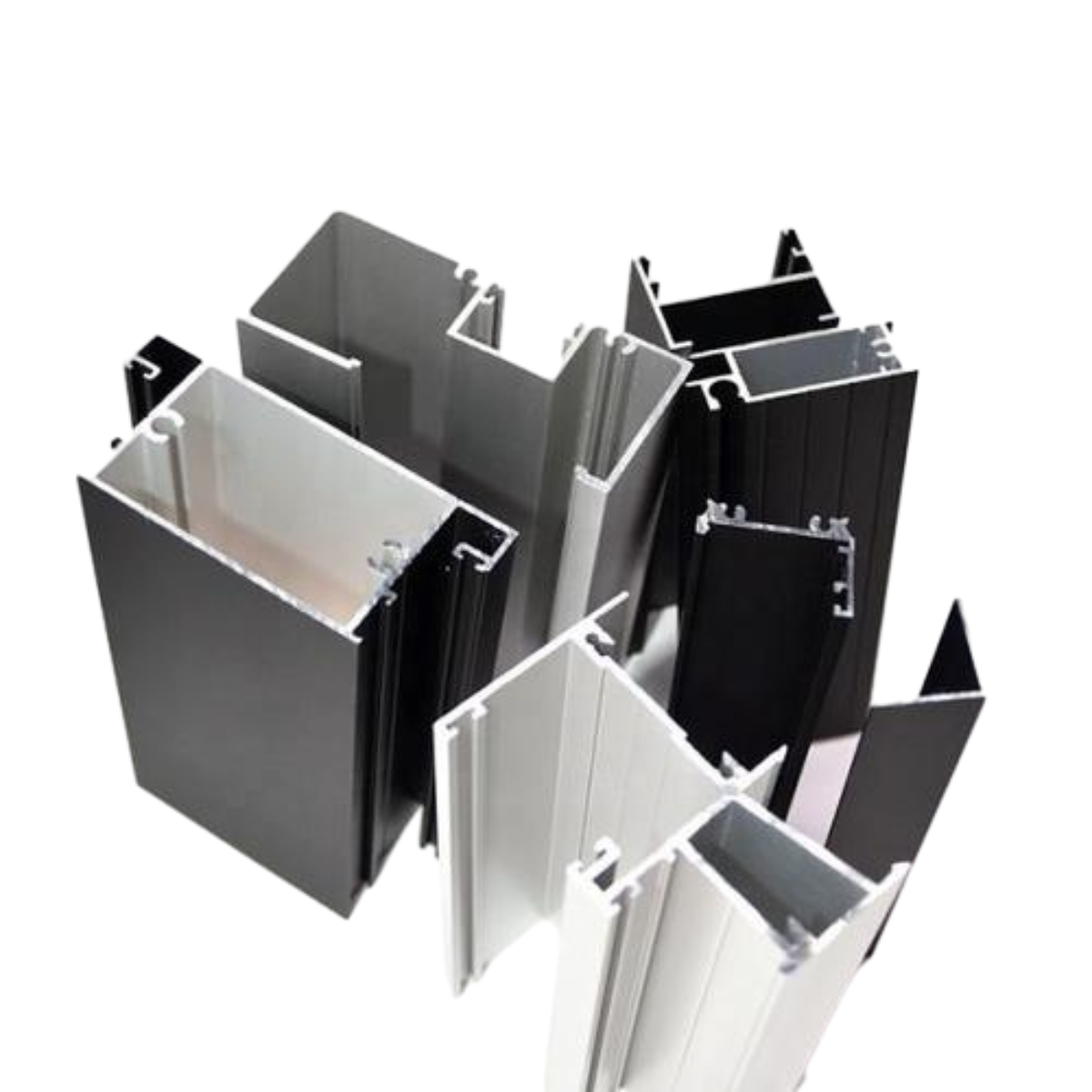

Aluminum profiles are extruded aluminum shapes with a wide variety of cross-sectional designs that are used in a broad range of applications. These profiles are produced by forcing aluminum through a die to create consistent shapes that can be tailored to specific needs. The inherent properties of aluminum—such as lightweight, corrosion resistance, and high strength-to-weight ratio—make Aluminum profiles a preferred choice in industries ranging from construction to automotive manufacturing. Unlike heavier materials like steel or wood, Aluminum profiles are easy to transport, install, and modify, while their resistance to rust ensures long-term durability even in harsh environmental conditions. Additionally, Aluminum profiles can be further enhanced through processes like anodizing or powder coating, which improve their aesthetic appeal and provide additional protection against wear and tear.

Aluminum profiles serve as the backbone for many structural and decorative elements in modern buildings, with a significant focus on their use in fenestration systems

Among the most common applications is the production of Aluminium extrusion profile, which are specialized Aluminum profiles crafted to meet the precise requirements of building components. Aluminium extrusion profile is created using advanced extrusion techniques that allow for complex cross-sections, such as hollow frames or reinforced edges, which are essential for supporting the weight and ensuring the stability of windows and doors. These profiles can be customized to fit different sizes and load-bearing needs, making them adaptable to both residential and commercial projects. For example, in high-rise buildings, Aluminium extrusion profile used in window frames must be designed to withstand strong winds and seismic activity, while those for residential doors may prioritize thermal insulation and soundproofing.

Aluminum profiles for windows and doors are a specific category of Aluminum profiles that combine functionality with energy efficiency and design flexibility

These profiles are engineered to address the unique demands of fenestration, such as maintaining a tight seal against weather elements and supporting glass panels of varying thicknesses. Aluminium profiles for windows and doors often feature hollow chambers that can be filled with insulation materials, reducing heat transfer and improving the overall energy efficiency of a building. This insulation capability is particularly important in regions with extreme temperatures, as it helps lower heating and cooling costs. Furthermore, these profiles can be manufactured in a wide range of colors and finishes, allowing them to complement any architectural style—from sleek modern designs to traditional aesthetics. The durability of Aluminum profiles for windows and doors also means they require minimal maintenance over time, unlike wood frames that may warp or rot, or vinyl frames that can become brittle in sunlight.

Aluminum profiles play a key role in the growing popularity of Slim profile aluminium windows, a modern fenestration trend that emphasizes minimalism and unobstructed views

Slim profile aluminium windows rely on narrow yet strong Aluminum profiles to create thin frame lines, which maximize the glass area and let in more natural light. The use of high-strength Aluminum profiles in these windows ensures that even with their slim design, they maintain the necessary structural integrity to support large glass panes. Additionally, the slim Aluminum profiles used in these windows can be paired with advanced hardware systems, such as hidden hinges and multi-point locking mechanisms, which enhance both the functionality and security of the windows. Slim profile aluminium windows are especially popular in contemporary homes, offices, and commercial spaces where a clean, open look is desired, as they blend seamlessly with modern interior and exterior designs while still offering the durability and energy efficiency associated with Aluminum profiles.

Aluminum profiles also offer significant advantages in terms of sustainability, which is a key consideration in modern construction

Aluminum is a fully recyclable material, and Aluminum profiles can be recycled repeatedly without losing their structural properties. This recyclability reduces the environmental impact of manufacturing, as recycling aluminum requires only a fraction of the energy needed to produce new aluminum from raw materials. Additionally, the long lifespan of Aluminum profiles means they do not need to be replaced frequently, further reducing waste. Even in specialized applications like Aluminium extrusion profile or Aluminum profiles for windows and doors, the recyclable nature of the material remains intact, making them a sustainable choice for eco-conscious builders and designers.

In summary, Aluminum profiles are indispensable components in modern construction and design, offering a unique blend of versatility, durability, and sustainability. From the customizable Aluminium extrusion profile that forms the basis of structural elements to the specialized Aluminum profiles for windows and doors that enhance energy efficiency, these profiles cater to a wide range of needs. The rise of Slim profile aluminium windows further showcases how Aluminum profiles can adapt to evolving design trends, providing sleek, functional solutions that prioritize both aesthetics and performance. Whether used in residential, commercial, or industrial projects, Aluminum profiles continue to stand out as a reliable, cost-effective, and eco-friendly option, solidifying their place as a cornerstone of modern building practices.

Aluminum Profiles FAQs

1. What are the primary advantages of using aluminum profiles?

The key advantages include their high strength-to-weight ratio, excellent corrosion resistance, and exceptional design flexibility. Aluminum profiles can be easily customized into complex cross-sectional shapes through the extrusion process. They are also highly sustainable, being 100% recyclable without any loss of quality.

2. How are aluminum profiles typically finished or treated?

Common finishing options for aluminum profiles include anodizing, which enhances corrosion resistance and allows for various colors, and powder coating, which provides a durable, scratch-resistant polymer coating in a wide spectrum of colors. Other treatments include mechanical brushing or polishing for a specific aesthetic.

3. What factors determine the strength of aluminum profiles?

The strength of aluminum profiles is primarily determined by the specific aluminum alloy used, such as the 6000 series which is common for extrusion. The geometric design of the cross-section also significantly impacts structural strength and stiffness. Heat treatment processes like T5 or T6 tempering further enhance the mechanical properties.

4. In which industries are aluminum profiles most commonly applied?

Aluminum profiles are ubiquitous across many industries. They are fundamental in construction for windows, doors, and curtain walls. In manufacturing, they are the core component of machine frames, assembly lines, and automation equipment. The transportation sector also relies heavily on them for vehicle and aerospace structures.

5. Why is the extrusion process so well-suited for creating aluminum profiles?

The extrusion process is ideal because it allows for the cost-effective production of continuous, complex shapes with a consistent cross-section. It facilitates the creation of profiles with multiple functionalities, such as integrated T-slots for easy assembly, which would be difficult or expensive to achieve with other manufacturing methods like machining or welding.

-

Plough Wheel Cast Iron Material Enhances Load-BearingNewsNov.10,2025

-

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNewsNov.10,2025

-

Rubber Strip Shock Absorption Protects Window EdgesNewsNov.10,2025

-

Aluminum Profiles High Corrosion Resistance Suits Coastal AreasNewsNov.10,2025

-

Window Handle Aluminum Material Ensures Lightweight DurabilityNewsNov.10,2025

-

Sliding Roller Plastic Housing Fits Aluminum Sliding WindowsNewsNov.10,2025

-

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing -

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating -

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges