Cast Iron Railheads - Durable, Decorative, Custom Castings

A field note on cast iron railheads in 2025: the spear point everyone still asks for

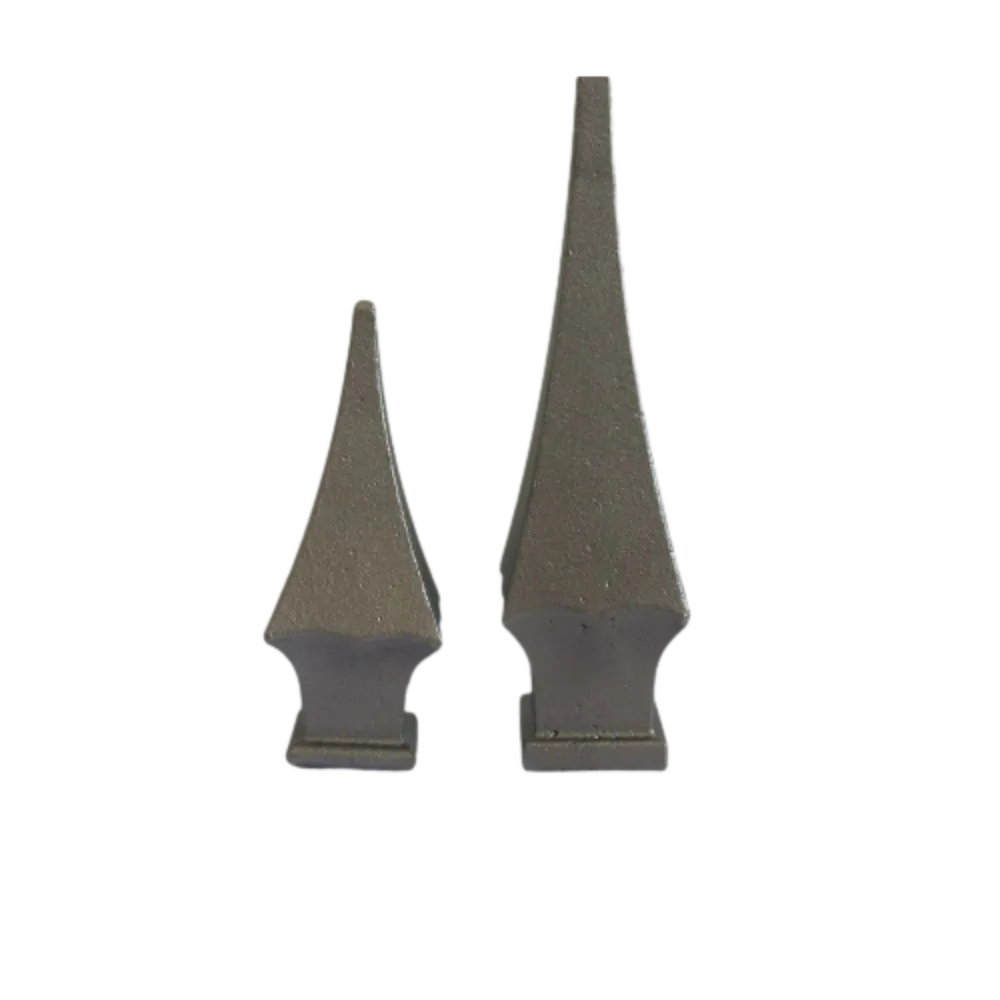

I’ve walked more fence lines than I care to admit, and—surprisingly—the classic spear point keeps winning bids. The why is simple: detail, weight, and longevity. The model I’m looking at today is the Cast Iron Spear Point Finial made in Shijiazhuang, Hebei, China. It’s a small piece, but it carries a lot of spec for such an old-school component.

Quick spec snapshot (real-world use may vary)

| Product name | Cast Iron Spear Point Finial |

| Overall size | H137 × W90 mm |

| Socket options | 1/2" and 5/8" I.D. (for typical pickets) |

| Material | Gray cast iron ≈ EN-GJL-200/250 or ASTM A48 Class 30–35 (vendor confirms) |

| Finish options | As-cast, powder-coated, or hot-dip galvanized; topcoat optional |

| Typical weight | ≈0.7 kg per piece (design-dependent) |

| Origin | Shijiazhuang, Hebei Province, China |

Process flow, testing, and service life

Materials: pig iron + clean steel scrap, carbon and silicon control; chill checks kept minimal for nicer detail. Methods: green sand molding, induction melt, controlled pour; then fettling, shot-blast, and machining of the socket. Coatings: hot-dip galvanizing per ISO 1461 (or EN ISO 1461) and architectural powder coat as needed. Testing: chemical analysis via spectrometer; hardness target HB 170–220; dimensional checks with jigs; coating thickness ≈80–120 μm (powder) or per zinc spec; corrosion screening via ASTM B117 / ISO 9227 salt spray (240–500 h typical before red rust with duplex systems). Expected service life: around 10–25 years depending on coating system and environment—coastal sites need galvanizing plus a quality topcoat, to be honest.

Where these actually get used

- Estate and residential fencing that needs a “period” look without the price of wrought iron.

- Municipal railings, parks, transit barriers—lots of repeatable, safe geometry.

- Heritage refurbishments where cast iron railheads must visually match historic stock.

Advantages? Weight that feels right, crisp ornament from iron’s fluidity, and honest durability. Many customers say they like the damping feel—iron deadens clangs compared to aluminum, which, I guess, matters on busy streets.

Vendor landscape (approximate, based on typical quotes)

| Feature | TJJ Iron Casting | Vendor A (EU) | Vendor B (Domestic) |

|---|---|---|---|

| MOQ | ≈500–1,000 pcs | Lower, but higher unit price | Varies; stock SKUs only |

| Lead time | 30–45 days after tooling | 15–30 days | Immediate for standard items |

| Customization | Logo, socket size, finish | Design tweaks only | Limited; off-the-shelf |

| QC & certs | ISO 9001, material certs on request | ISO 9001 common | COC; limited mill data |

Customization notes

Tooling for new cast iron railheads shapes is usually a one-time charge; modest changes—like switching socket from 1/2" to 5/8"—are easier. Finishes can be duplex (galvanize + powder), and I’d recommend it for coastal ZIPs. Engraved logos? Possible, but check draft angles.

Mini case notes

- Historic park retrofit: 1,800 pcs, duplex-coated, passed 500 h salt spray with no red rust; inspectors happy.

- Coastal estate gate: galvanize + polyester topcoat; customer feedback after 18 months—“still looks new”.

Standards, data, and paperwork

Base iron per EN 1561 or ASTM A48. Galvanizing per ISO 1461. Powder per manufacturer TDS; adhesion checked to ASTM D3359. Corrosion screening to ASTM B117 / ISO 9227. Factory quality systems typically ISO 9001. Coatings can be supplied RoHS/REACH compliant on request. For specifiers: ask for hardness logs (HB 170–220), composition printouts, and coating thickness reports. That covers 90% of RFIs on cast iron railheads.

Authoritative citations:

- EN 1561: Founding – Grey cast irons.

- ASTM A48/A48M: Standard Specification for Gray Iron Castings.

- ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles.

- ASTM B117 / ISO 9227: Salt Spray (Fog) Testing methods.

- ASTM D3359: Standard Test Methods for Rating Adhesion by Tape Test.

-

Plough Wheel Cast Iron Material Enhances Load-BearingNewsNov.10,2025

-

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNewsNov.10,2025

-

Rubber Strip Shock Absorption Protects Window EdgesNewsNov.10,2025

-

Aluminum Profiles High Corrosion Resistance Suits Coastal AreasNewsNov.10,2025

-

Window Handle Aluminum Material Ensures Lightweight DurabilityNewsNov.10,2025

-

Sliding Roller Plastic Housing Fits Aluminum Sliding WindowsNewsNov.10,2025

-

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing -

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating -

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges