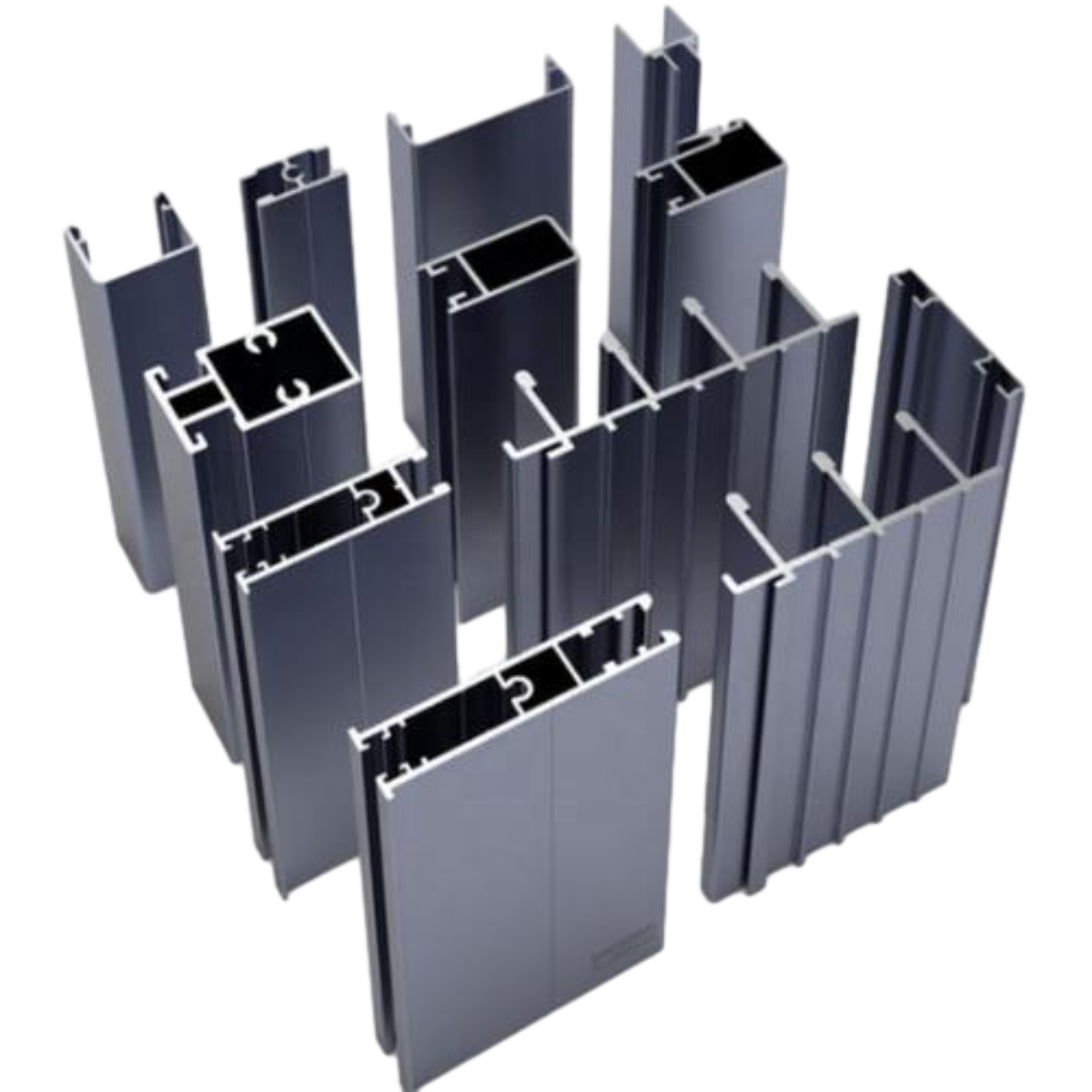

Aluminium Windows Profiles: The Backbone of High-Performance Window Systems

Aluminium Windows Profiles, crafted through precision and innovative manufacturing processes, stand as the pinnacle of excellent design, delivering unparalleled performance and versatility for residential, commercial, and industrial projects. These profiles serve as the structural foundation of aluminum windows, defining their durability, thermal efficiency, and aesthetic appeal. Unlike traditional materials such as wood or vinyl, Aluminium Windows Profiles boast high strength-to-weight ratios—they are lightweight enough to simplify transportation and installation yet robust enough to withstand harsh weather conditions, from heavy rain and strong winds to extreme temperatures. Their inherent resistance to corrosion, thanks to natural oxide layers or additional coatings, ensures long-term performance without warping, rotting, or fading, making them a reliable choice for both interior and exterior window applications.

Aluminium Windows Profiles excel in customization, allowing for tailored solutions that meet the unique needs of different building designs

Manufacturers can adjust the shape, thickness, and cross-sectional structure of Aluminium Windows Profiles to accommodate various window types, including casement, sliding, awning, and tilt-and-turn styles. For example, sliding window systems require sleek, low-profile Aluminium Windows Profiles to enable smooth gliding, while casement windows need reinforced profiles to support hinge mechanisms and withstand wind pressure. Additionally, these profiles can be integrated with thermal breaks—insulating strips placed within the profile structure—to reduce heat transfer, enhancing the energy efficiency of windows. This customization not only improves the functional performance of windows but also aligns with diverse architectural aesthetics, from modern minimalist designs to classic styles.

Aluminum profiles, a broader category that includes Aluminium Windows Profiles, share core material advantages but are optimized specifically for window applications to balance strength and functionality

While general aluminum profiles may be used in construction frameworks or furniture, aluminum profiles for windows undergo additional refinements, such as precision cutting and surface treatments, to ensure seamless integration with window components like handles, locks, and glass panels. These profiles feature prefabricated grooves and holes that simplify the assembly process, reducing installation time and minimizing errors. Moreover, aluminum profiles for windows are often designed with drainage channels to prevent water accumulation, a critical detail that protects the window structure and extends its lifespan. Whether used in high-rise residential buildings or industrial warehouses, these specialized aluminum profiles maintain consistent performance across diverse environments.

Aluminium Windows Profiles rely on advanced production techniques, with the aluminium extrusion profile process being a key step in their manufacturing

The aluminium extrusion profile process involves forcing heated aluminum alloy through a custom die to create the desired cross-sectional shape, ensuring uniformity and precision in every piece. This process allows for the creation of complex profiles with intricate details—such as multi-chambered structures for improved insulation or thin-walled designs for weight reduction—without compromising strength. After extrusion, Aluminium Windows Profiles undergo surface treatments like anodizing, powder coating, or electrophoretic coating. Anodizing enhances corrosion resistance and adds a matte finish, while powder coating offers a wide range of colors to match building exteriors. These treatments not only improve the durability of Aluminium Windows Profiles but also expand their aesthetic possibilities.

Aluminium Windows Profiles adapt seamlessly to the evolving demands of sustainable building practices, making them a preferred choice for eco-friendly projects

Their recyclability is a standout feature—aluminum can be recycled repeatedly without losing its structural properties, reducing the environmental impact of window production. Additionally, the thermal efficiency of Aluminium Windows Profiles, especially those with thermal breaks, helps reduce building energy consumption by minimizing heat loss in winter and heat gain in summer. This translates to lower carbon footprints for buildings and reduced utility costs for occupants. Furthermore, the long lifespan of Aluminium Windows Profiles means fewer replacements over time, cutting down on waste generated by discarded window systems.

In summary, Aluminium Windows Profiles are the cornerstone of modern, high-performance window systems, combining precision engineering, durability, and versatility to meet the needs of residential, commercial, and industrial projects. As a specialized subset of aluminum profiles, they undergo tailored manufacturing processes—including the aluminium extrusion profile method—to deliver structures that support diverse window types and integrate with essential components. Their resistance to corrosion, customization capabilities, and alignment with sustainable practices further solidify their role in contemporary architecture. As building standards continue to emphasize energy efficiency and durability, Aluminium Windows Profiles will remain a vital component, evolving with advancements in material science and manufacturing to deliver even greater performance and value for future construction projects.

Aluminium Windows Profiles FAQs

1. What are the key advantages of using aluminum window profiles in construction?

Aluminum window profiles offer exceptional strength-to-weight ratio, corrosion resistance, and long-term durability for various architectural applications.

2. How do aluminum window profiles contribute to energy efficiency in buildings?

These profiles can be thermally broken with insulating barriers that significantly reduce heat transfer and improve overall building energy performance.

3. What design flexibility do aluminum window profiles provide for modern architecture?

The material allows for slim sightlines, large glass expanses, and custom shapes while maintaining structural integrity and meeting safety requirements.

4. How sustainable are aluminum window profiles as a building material?

Aluminum is infinitely recyclable without quality loss, and modern production methods have reduced the environmental impact of manufacturing processes.

5. What maintenance requirements do aluminum window profiles typically have?

They require minimal maintenance due to natural oxidation resistance and can be finished with durable powder coatings that retain color and protect against weathering.

-

Plough Wheel Cast Iron Material Enhances Load-BearingNewsNov.10,2025

-

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNewsNov.10,2025

-

Rubber Strip Shock Absorption Protects Window EdgesNewsNov.10,2025

-

Aluminum Profiles High Corrosion Resistance Suits Coastal AreasNewsNov.10,2025

-

Window Handle Aluminum Material Ensures Lightweight DurabilityNewsNov.10,2025

-

Sliding Roller Plastic Housing Fits Aluminum Sliding WindowsNewsNov.10,2025

-

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing -

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating -

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges