Sliding Rollers and Their Applications in Home & Commercial Settings

Sliding roller is a fundamental component in various sliding mechanisms, designed to reduce friction between moving parts and enable smooth, effortless operation of sliding structures in both residential and commercial spaces. From small household items to large industrial installations, sliding roller plays a critical role in ensuring that sliding elements—such as doors, gates, and windows—function reliably over time. Unlike fixed components, sliding roller allows for linear movement, distributing weight evenly to prevent wear and tear on the sliding structure. For example, in a typical sliding closet door, sliding roller is mounted at the top or bottom of the door panel, gliding along a track to open and close the door without jamming. Sliding roller comes in diverse materials, including plastic, metal, and rubber, each selected based on the weight of the sliding structure and the frequency of use. Just as window handles are essential home items that blend functionality with aesthetic appeal, sliding roller is a behind-the-scenes essential that ensures daily convenience—without well-functioning sliding roller, even the most stylish sliding door or window would become cumbersome to operate.

Sliding Door Roller is a specialized type of sliding roller tailored explicitly for sliding doors, which are widely used in homes, offices, and retail spaces for their space-saving design and modern appearance

Unlike generic sliding roller, Sliding Door Roller is engineered to support the heavier weight of door panels (which can range from lightweight aluminum to solid wood) and withstand frequent use. For instance, in a home’s patio sliding door, Sliding Door Roller is often made of durable stainless steel with a rubberized outer layer—this combination provides strength to hold the door’s weight while minimizing noise during movement. Sliding Door Roller can be mounted in different configurations: bottom-mounted Sliding Door Roller is common for heavier doors, as it distributes weight directly to the floor track, while top-mounted versions are used for lighter doors to avoid floor track damage. Similar to how window handles add charm to a room, Sliding Door Roller contributes to the overall user experience of sliding doors—high-quality Sliding Door Roller ensures that the door opens and closes with a gentle push, enhancing the comfort of daily life.

Sliding wheel is a term often used interchangeably with sliding roller, referring to the circular component that enables sliding motion in various mechanical systems, from small household tools to large sliding structures

While sliding roller typically emphasizes the entire rolling mechanism (including the axle and housing), sliding wheel specifically denotes the circular part that comes into direct contact with the track. Sliding wheel is a key element in sliding roller assemblies, as its material and design directly impact friction levels and durability. For example, in a sliding drawer, the sliding wheel (part of the drawer’s sliding roller system) is usually made of high-density plastic, which is lightweight and resistant to scratches, ensuring the drawer slides smoothly in and out. Sliding wheel also varies in size: small sliding wheels are used in items like sliding storage bins, while larger sliding wheels are integrated into sliding roller systems for heavy-duty applications like industrial sliding gates. In home settings, sliding wheel works alongside other essential components—just as window handles are necessary for opening and closing windows, sliding wheel is necessary for the smooth operation of sliding elements that make homes more functional.

Sliding gate rollers are heavy-duty sliding roller units designed for large sliding gates, which are commonly used in residential driveways, commercial parking lots, and industrial facilities to control access and ensure security

Unlike standard sliding roller or Sliding Door Roller, sliding gate rollers must support extremely heavy weights (often several hundred pounds) and withstand outdoor conditions like rain, snow, and extreme temperatures. Sliding gate rollers are typically made of galvanized steel or cast iron for corrosion resistance, with large, thick sliding wheels that provide stability and reduce pressure on the gate track. For example, a residential driveway sliding gate relies on two or more sliding gate rollers mounted along the gate’s bottom edge, gliding along a concrete or metal track to open and close the gate smoothly. Sliding gate rollers also often include sealed bearings to prevent dust and debris from entering, which would otherwise cause jamming—this feature ensures long-term reliability even in harsh environments. While sliding gate rollers are less visible than window handles, they are equally important for property security and convenience, as a malfunctioning sliding gate roller can leave a property vulnerable or make the gate impossible to operate.

Windows roller is a specialized sliding roller designed for sliding windows, which are popular in homes and apartments for their ease of use and ability to allow maximum natural light.

Windows roller is smaller and more compact than Sliding Door Roller or sliding gate rollers, as sliding windows are lighter and require less force to operate. Typically mounted at the bottom of the window sash, windows roller glides along a narrow track, enabling the window to slide horizontally or vertically (in the case of double-hung sliding windows). Windows roller is often made of plastic or nylon, materials that are lightweight, quiet, and resistant to wear from frequent opening and closing. For example, in a kitchen sliding window, windows roller ensures that the window can be easily slid open to let in fresh air, even after years of use. Windows roller works in tandem with window handles—while window handles provide a grip to push or pull the window, windows roller ensures that the movement is smooth and effortless. A well-maintained windows roller prevents the window from sticking or becoming misaligned, just as a sturdy window handle prevents slipping and ensures safe operation.

In summary, sliding roller, along with its specialized variants—Sliding Door Roller, sliding wheel, sliding gate rollers, and windows roller—forms a versatile family of components that enable smooth, reliable sliding motion in countless residential and commercial applications. Sliding roller serves as the core, providing friction reduction and weight distribution for all sliding systems, while each specialized type caters to specific needs: Sliding Door Roller for heavy door panels, sliding wheel for general rolling motion, sliding gate rollers for large security gates, and windows roller for compact sliding windows. Just as window handles are essential for adding charm and functionality to windows, these sliding components are essential for the practical operation of sliding structures—without them, sliding doors, gates, and windows would be difficult to use or prone to damage. Whether in a home’s bedroom, a commercial storefront, or an industrial facility, these sliding components work behind the scenes to enhance convenience, security, and comfort, making them indispensable in modern living and working spaces. As design and material technologies advance, sliding roller and its variants will continue to evolve, offering even greater durability, efficiency, and compatibility with diverse sliding systems.

Sliding Door Roller FAQs

1. What are the key features of a high-quality sliding door roller?

High-quality sliding door rollers are characterized by smooth and quiet operation, durability, and easy adjustability. They are typically constructed from robust materials like stainless steel or hardened nylon, and often feature built-in noise reduction technology for a seamless user experience.

2. How does the design of a sliding door roller impact its functionality?

The design of a sliding door roller directly influences its load capacity, smoothness of glide, and longevity. A well-engineered roller with a precision bearing system ensures the door moves effortlessly along the track without wobbling or jumping, even under significant weight.

3. What types of sliding door rollers are available for different door weights?

There are various types of sliding door rollers designed for specific weight classes. Light-duty rollers are for hollow-core or lightweight doors, while heavy-duty rollers with double or triple bearings are engineered to support solid wood or large glass doors without sagging.

4. Why is proper maintenance important for sliding door rollers?

Proper maintenance, such as regular cleaning of the track and occasional lubrication, is crucial to prevent dirt and debris from causing premature wear. This ensures the rollers continue to function smoothly and quietly, extending the product's overall service life.

5. Can sliding door rollers be easily replaced if they wear out?

Yes, most sliding door rollers are designed for straightforward replacement. Systems often feature an adjustable mechanism that allows for easy height correction and roller removal without the need to dismantle the entire door from its frame.

-

Plough Wheel Cast Iron Material Enhances Load-BearingNewsNov.10,2025

-

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNewsNov.10,2025

-

Rubber Strip Shock Absorption Protects Window EdgesNewsNov.10,2025

-

Aluminum Profiles High Corrosion Resistance Suits Coastal AreasNewsNov.10,2025

-

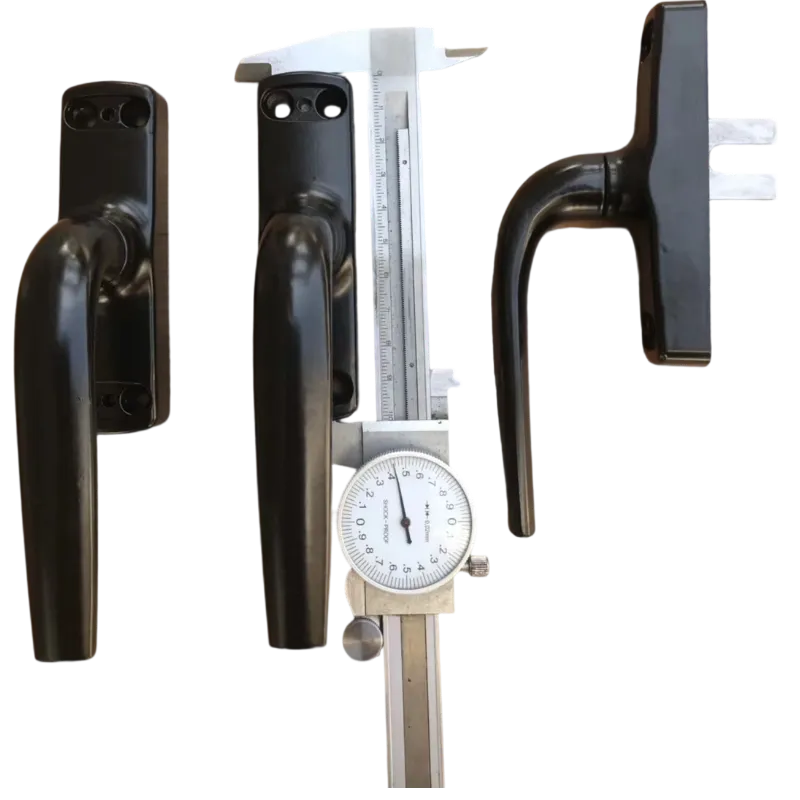

Window Handle Aluminum Material Ensures Lightweight DurabilityNewsNov.10,2025

-

Sliding Roller Plastic Housing Fits Aluminum Sliding WindowsNewsNov.10,2025

-

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing -

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating -

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges