Sliding Rollers: Essential Components for Smooth Sliding Mechanisms

Sliding roller is a fundamental component in various sliding systems, designed to reduce friction between moving parts and ensure seamless operation of doors, gates, and windows. These small yet critical devices come in diverse designs, materials, and sizes, tailored to meet the specific load-bearing and usage demands of different applications. Unlike fixed hinges that limit movement to a single axis, sliding roller enables linear motion, making it ideal for spaces where swing-open mechanisms would waste space or cause inconvenience. From residential Sliding Door Rollers to industrial sliding gate rollers, the performance of sliding roller directly impacts the usability, durability, and safety of the entire sliding system. Common materials used for sliding roller include stainless steel, nylon, and rubber, each offering unique benefits—stainless steel for strength and corrosion resistance, nylon for quiet operation, and rubber for shock absorption.

Sliding Door Roller is a specialized type of sliding roller engineered explicitly for residential and commercial sliding doors, such as patio doors, closet doors, and interior partition doors

This component is designed to support the weight of the door while minimizing friction, allowing users to open and close doors with minimal effort. Sliding Door Roller typically consists of a wheel, a bracket, and a bearing system; the sliding wheel’s diameter and width vary based on the door’s weight and the track’s design. For example, heavy glass patio doors require larger, more robust Sliding Door Rollers with stainless steel sliding wheels to handle the weight, while lightweight closet doors can use smaller nylon sliding wheels for quieter operation. Many Sliding Door Rollers also feature adjustable brackets, which let users fine-tune the roller’s height to ensure the door aligns perfectly with the track and operates smoothly without sticking.

Sliding wheel, a key part of sliding roller assemblies, plays a vital role in determining the overall performance and lifespan of sliding systems

This circular component is the point of contact between the sliding roller and the track, so its material and design must match the system’s specific needs. Sliding wheels made of hard materials like stainless steel or hardened plastic excel in high-load applications, such as sliding gate rollers, where they need to withstand constant use and exposure to outdoor elements. In contrast, soft rubber sliding wheels are preferred for indoor sliding systems, like office partition doors, as they reduce noise and prevent scratches on the track. The surface texture of a sliding wheel also matters—smooth sliding wheels work best on flat, polished tracks, while grooved sliding wheels are designed for V-shaped or U-shaped tracks to prevent derailing and ensure stable movement.

Sliding gate rollers are heavy-duty sliding roller units built to handle the large size and weight of sliding gates, commonly used in driveways, industrial yards, and commercial properties

Unlike residential Sliding Door Rollers, sliding gate rollers must endure outdoor conditions, including rain, snow, dust, and temperature fluctuations, so they are often constructed with corrosion-resistant materials like galvanized steel or powder-coated aluminum. These sliding roller assemblies typically feature large-diameter sliding wheels (up to 10 inches or more) to distribute the gate’s weight evenly and reduce pressure on the track. Many sliding gate rollers also include sealed bearings to prevent dirt and moisture from entering, which would otherwise cause friction buildup and premature wear. Additionally, sliding gate rollers may be paired with guide rollers—smaller sliding roller components that keep the gate aligned with the track and prevent it from swaying during operation.

Sliding roller technology continues to evolve to meet the growing demands for efficiency, durability, and sustainability in modern sliding systems

Manufacturers are now developing sliding roller designs with recycled materials, such as nylon made from post-consumer plastic, to reduce environmental impact. For Sliding Door Rollers used in energy-efficient buildings, some models integrate thermal breaks into their brackets to minimize heat transfer, aligning with green building standards. In sliding gate rollers, smart features like wear sensors are being added—these sensors detect when the sliding wheel or bearing is deteriorating and send alerts to users, allowing for timely maintenance and preventing unexpected system failures. Even basic sliding wheel designs are being optimized, with improved bearing systems that extend lifespan and reduce the need for frequent lubrication.

In summary, sliding roller is an indispensable component that powers the smooth operation of countless sliding systems, from everyday Sliding Door Rollers in homes to heavy-duty sliding gate rollers in industrial settings. The sliding wheel, as the core part of sliding roller assemblies, dictates key performance factors like friction levels, noise, and durability, while the specific design of each sliding roller type is tailored to its application’s unique demands. As technology advances, sliding roller systems are becoming more sustainable, durable, and user-friendly, ensuring they continue to meet the needs of modern construction and design. Whether in residential, commercial, or industrial spaces, sliding roller remains a quiet yet essential force that enhances functionality, saves space, and improves the overall user experience of sliding mechanisms.

Sliding Roller FAQs

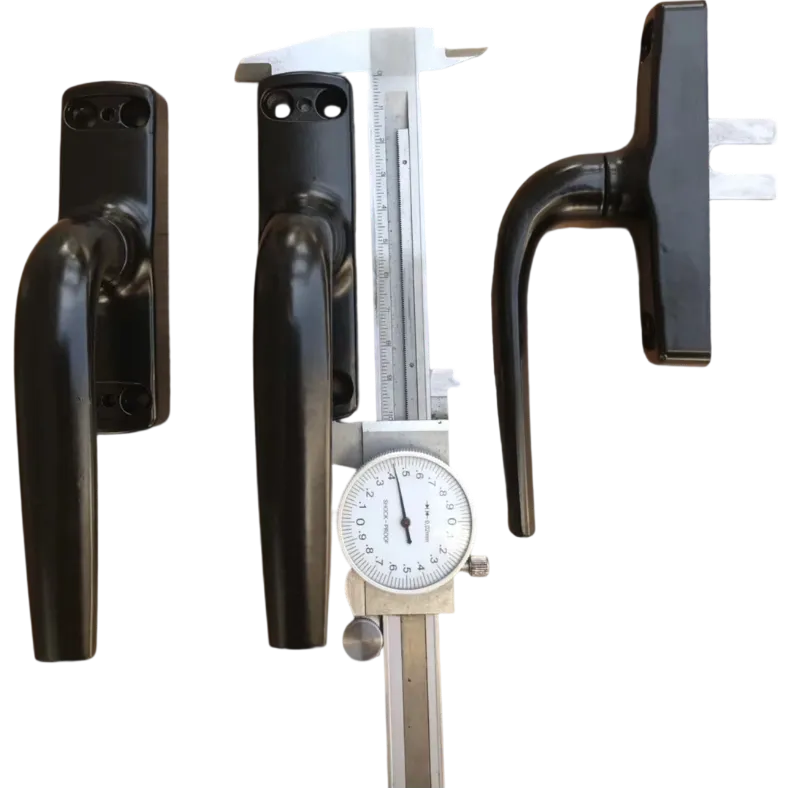

1. What types of sliding roller systems are compatible with aluminum window handles?

Modern sliding roller mechanisms are engineered for smooth operation with both contemporary and classic aluminum window handles, ensuring effortless window movement.

2. How does the sliding roller mechanism affect the functionality of a vintage aluminum window handle?

A well-maintained sliding roller is crucial for restoring the original smooth gliding motion to windows equipped with older aluminum window handles.

3. Can a new sliding roller system be integrated with existing aluminum window handles?

Yes, contemporary sliding roller tracks and carriages can often be fitted to work seamlessly with a building's original aluminum window handles.

4. Why is the sliding roller important for the durability of aluminum window handles?

The sliding roller absorbs the friction and weight of the window sash, preventing premature wear and strain on the aluminum window handles during operation.

5. What should be considered when maintaining the sliding roller for windows with aluminum window handles?

Regular cleaning and lubrication of the sliding roller channel are essential to prevent sticking and ensure the long-term performance of the aluminum window handles.

-

Plough Wheel Cast Iron Material Enhances Load-BearingNewsNov.10,2025

-

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNewsNov.10,2025

-

Rubber Strip Shock Absorption Protects Window EdgesNewsNov.10,2025

-

Aluminum Profiles High Corrosion Resistance Suits Coastal AreasNewsNov.10,2025

-

Window Handle Aluminum Material Ensures Lightweight DurabilityNewsNov.10,2025

-

Sliding Roller Plastic Housing Fits Aluminum Sliding WindowsNewsNov.10,2025

-

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing

Plough Wheel Cast Iron Material Enhances Load-BearingNov-10-2025Plough Wheel Cast Iron Material Enhances Load-Bearing -

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating

Cast Iron Cooking Stove Heat Retention Ensures Even Food HeatingNov-10-2025Cast Iron Cooking Stove Heat Retention Ensures Even Food Heating -

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges

Rubber Strip Shock Absorption Protects Window EdgesNov-10-2025Rubber Strip Shock Absorption Protects Window Edges